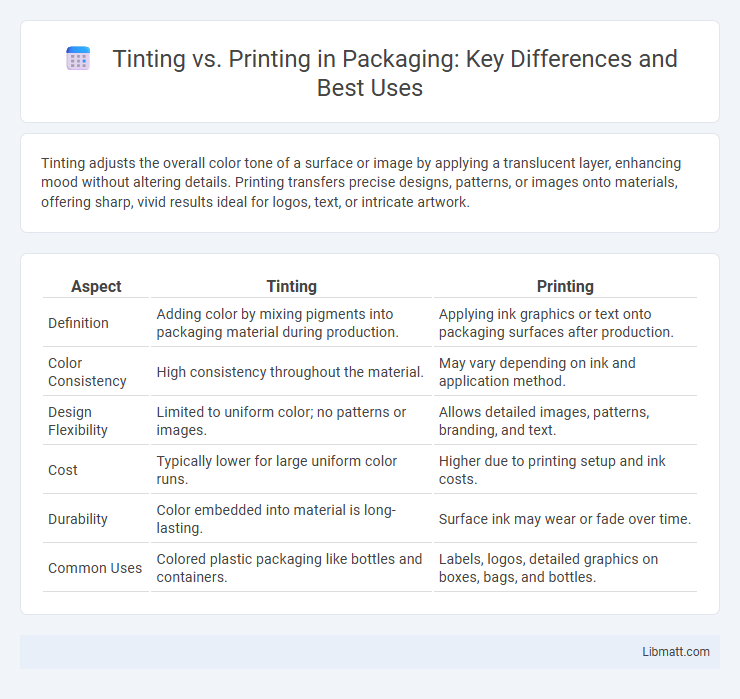

Tinting adjusts the overall color tone of a surface or image by applying a translucent layer, enhancing mood without altering details. Printing transfers precise designs, patterns, or images onto materials, offering sharp, vivid results ideal for logos, text, or intricate artwork.

Table of Comparison

| Aspect | Tinting | Printing |

|---|---|---|

| Definition | Adding color by mixing pigments into packaging material during production. | Applying ink graphics or text onto packaging surfaces after production. |

| Color Consistency | High consistency throughout the material. | May vary depending on ink and application method. |

| Design Flexibility | Limited to uniform color; no patterns or images. | Allows detailed images, patterns, branding, and text. |

| Cost | Typically lower for large uniform color runs. | Higher due to printing setup and ink costs. |

| Durability | Color embedded into material is long-lasting. | Surface ink may wear or fade over time. |

| Common Uses | Colored plastic packaging like bottles and containers. | Labels, logos, detailed graphics on boxes, bags, and bottles. |

Understanding Tinting: Definition and Process

Tinting involves adding white to a pure color to create a lighter shade, altering its hue without changing the base pigment. This process is essential in various industries, such as paint manufacturing and digital design, where precise control over color lightness is required. Understanding tinting enables accurate color customization and improved visual aesthetics in both physical and digital media.

What is Printing? Core Concepts Explained

Printing is the process of reproducing text and images onto various substrates using techniques such as offset, digital, or screen printing. It involves transferring ink from a carrier onto a surface, ensuring high precision and consistency in color and detail. This method is widely used for mass production of materials like books, labels, packaging, and promotional items, emphasizing durability and replication accuracy.

Key Differences Between Tinting and Printing

Tinting alters the color of a surface or material by adding a translucent layer of pigment, which changes its overall hue without covering details, whereas printing applies ink or toner onto a substrate to create distinct images, patterns, or text. Tinting is commonly used in art and design to adjust tones subtly, while printing is essential for producing precise graphics and reproducing detailed visuals. Your choice between tinting and printing depends on whether you want to enhance color depth or achieve high-resolution image replication.

Materials Used in Tinting vs Printing

Tinting primarily involves the use of dyes and pigments that are absorbed into the surface of materials such as glass, textiles, or automotive windows, altering their color without adding texture or thickness. Printing relies on inks and toners applied on top of substrates like paper, fabric, or plastic, creating detailed images or patterns with varying degrees of opacity and vibrancy. Understanding the differences in these materials helps you choose the right method for durability, colorfastness, and project requirements.

Advantages of Tinting for Customization

Tinting offers precise color customization by allowing subtle adjustments to achieve unique shades that match brand identities exactly. It enhances consistency across different product batches by integrating color directly into the material rather than applying it externally. This method also increases durability, as tinted materials resist fading and wear better than printed surfaces.

Benefits of Printing for Design Quality

Printing offers superior design quality by producing crisp, vibrant colors and intricate details that tinting cannot achieve. High-resolution printing ensures consistent color accuracy and sharpness across various materials, enhancing visual appeal. Advanced printing techniques also allow for complex patterns and gradients, elevating the overall aesthetic and customization possibilities.

Cost Comparison: Tinting Versus Printing

Tinting generally offers a more cost-effective solution for small to medium-scale projects due to lower setup expenses and minimal material usage. Printing incurs higher initial costs from equipment, plates, or digital files but becomes more economical at large volumes through economies of scale. Your choice between tinting and printing should consider project size and budget, balancing upfront costs against long-term efficiency.

Durability and Maintenance Factors

Tinting offers enhanced durability by applying a protective film that resists scratches, UV rays, and fading, reducing the need for frequent maintenance. Printing on surfaces may show signs of wear and color degradation over time, requiring touch-ups or replacements to maintain appearance. Maintenance for tinted materials is generally simpler, involving gentle cleaning to preserve the film's integrity, while printed items often need specialized care to avoid ink smudging or peeling.

Ideal Applications for Tinting and Printing

Tinting is ideal for automotive and architectural glass applications where precise color matching and enhanced UV protection are essential for comfort and energy efficiency. Printing excels in packaging, textiles, and advertising, enabling detailed graphics, logos, and patterns with high durability and color vibrancy. Choosing between tinting and printing depends on material type, visual requirements, and functional properties like light transmission and resistance.

Choosing the Right Method for Your Project

When deciding between tinting and printing for your project, consider the material and desired finish; tinting adds a translucent color layer ideal for glass and plastics, enhancing light diffusion without obscuring details. Printing applies opaque or translucent inks directly onto surfaces, allowing for intricate designs and vibrant colors, making it ideal for fabric, paper, and promotional materials. Evaluate project goals, budget, and durability requirements to select the method that best aligns with your creative vision and functional needs.

Tinting vs printing Infographic

libmatt.com

libmatt.com