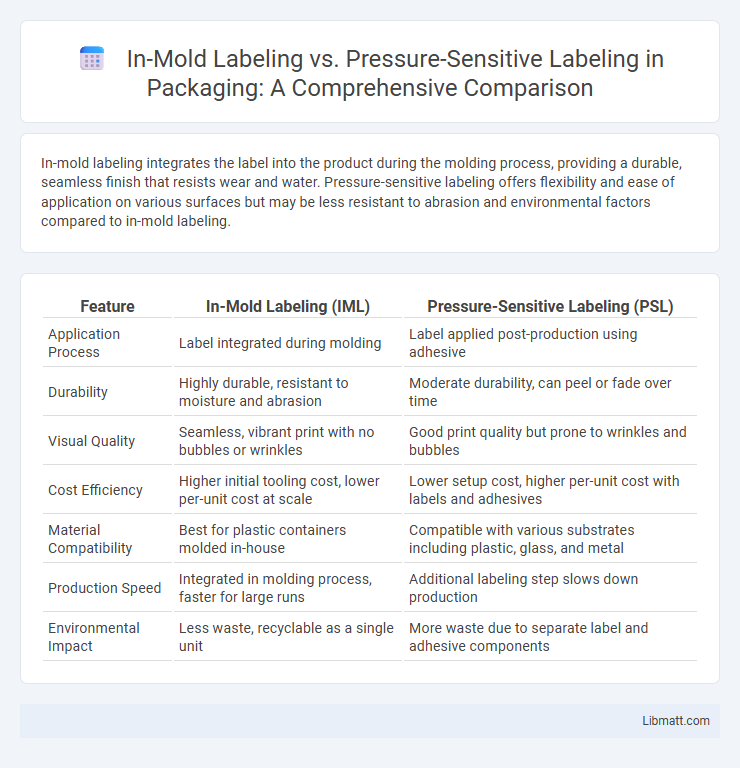

In-mold labeling integrates the label into the product during the molding process, providing a durable, seamless finish that resists wear and water. Pressure-sensitive labeling offers flexibility and ease of application on various surfaces but may be less resistant to abrasion and environmental factors compared to in-mold labeling.

Table of Comparison

| Feature | In-Mold Labeling (IML) | Pressure-Sensitive Labeling (PSL) |

|---|---|---|

| Application Process | Label integrated during molding | Label applied post-production using adhesive |

| Durability | Highly durable, resistant to moisture and abrasion | Moderate durability, can peel or fade over time |

| Visual Quality | Seamless, vibrant print with no bubbles or wrinkles | Good print quality but prone to wrinkles and bubbles |

| Cost Efficiency | Higher initial tooling cost, lower per-unit cost at scale | Lower setup cost, higher per-unit cost with labels and adhesives |

| Material Compatibility | Best for plastic containers molded in-house | Compatible with various substrates including plastic, glass, and metal |

| Production Speed | Integrated in molding process, faster for large runs | Additional labeling step slows down production |

| Environmental Impact | Less waste, recyclable as a single unit | More waste due to separate label and adhesive components |

Introduction to In-Mold and Pressure-Sensitive Labeling

In-mold labeling (IML) integrates the label directly into the plastic container during the molding process, resulting in a seamless, durable surface that resists peeling and provides high-quality graphics. Pressure-sensitive labeling (PSL) involves applying pre-printed adhesive labels onto containers post-production, offering flexibility, ease of application, and cost-effectiveness for short runs or variable packaging designs. Both labeling methods serve distinct packaging needs, with IML preferred for durability and premium appearance, while PSL excels in adaptability and broader material compatibility.

Overview of In-Mold Labeling Technology

In-mold labeling (IML) integrates labels directly into the plastic container during the molding process, creating a seamless, durable finish resistant to wear and moisture. This technology enhances product aesthetics and branding by allowing high-resolution, full-color graphics embedded in the container walls. In contrast to pressure-sensitive labels, IML offers superior durability and recyclability, making it ideal for food, beverage, and consumer goods packaging.

Understanding Pressure-Sensitive Labeling

Pressure-sensitive labeling (PSL) employs adhesive-backed labels that adhere instantly to container surfaces without heat or solvents, offering versatility across materials such as glass, plastic, and metal. This method enables high-speed application suitable for diverse shapes and sizes, ensuring efficient production lines in industries like food, beverage, and pharmaceuticals. Compared to in-mold labeling, PSL provides flexibility in label design changes and is often more cost-effective for short to medium production runs.

Material Compatibility and Selection

In-mold labeling offers superior durability by integrating labels directly into the mold during the plastic forming process, making it compatible with materials like polypropylene and polyethylene used in injection molding. Pressure-sensitive labeling provides greater flexibility with a broad range of materials, including PET, glass, and metal, where label adhesion relies on adhesive properties rather than molding integration. Your choice depends on the base material and desired durability, with in-mold labeling excelling in applications requiring seamless, long-lasting labels.

Design Flexibility and Aesthetic Options

In-mold labeling offers superior design flexibility by allowing full-color graphics and complex shapes to be integrated directly into the container during the molding process, ensuring a seamless and durable finish. Pressure-sensitive labeling provides a wide range of aesthetic options, including textured finishes, metallic foils, and transparent films, which can be applied post-production for easy customization. Your choice depends on whether you prioritize long-lasting, vibrant designs or versatile, cost-effective labels that can be quickly updated.

Efficiency and Production Speed Comparison

In-mold labeling (IML) offers higher efficiency and faster production speeds by integrating the label application directly into the molding process, eliminating secondary labeling steps. Pressure-sensitive labeling (PSL) requires a separate application phase, which can slow down production and increase labor costs. IML typically results in reduced cycle times and increased automation compatibility compared to PSL, making it preferable for high-volume manufacturing environments.

Cost Analysis: In-Mold vs Pressure-Sensitive Labels

In-mold labeling (IML) typically incurs higher initial costs due to specialized equipment and mold modifications, but offers lower per-unit costs in high-volume production by integrating labels directly into the packaging during molding. Pressure-sensitive labels (PSL) feature lower upfront expenses and greater flexibility for small runs or frequent design changes, yet come with higher material and application costs over time. Your choice depends on volume, budget constraints, and the desired durability and appearance of the label.

Durability and Performance in Different Environments

In-mold labeling offers superior durability by fusing the label directly into the container's surface, making it highly resistant to abrasion, moisture, and chemicals, ideal for harsh environments like industrial or outdoor settings. Pressure-sensitive labeling provides good adhesion and flexibility but can peel or degrade under extreme temperatures, moisture, or heavy wear, making it less reliable for long-term exposure to challenging conditions. Your choice should consider the environmental stressors the product will face, with in-mold labeling delivering enhanced performance where durability is critical.

Sustainability and Environmental Impact

In-mold labeling significantly reduces waste by integrating the label into the container during the molding process, eliminating the need for additional adhesives and separate label disposal. Pressure-sensitive labeling relies on adhesives that can complicate recycling efforts and increase environmental impact due to non-recyclable label and liner materials. Choosing in-mold labeling supports your commitment to sustainability by enhancing recyclability and minimizing resource consumption.

Choosing the Right Labeling Method for Your Application

Selecting the right labeling method depends on your product's packaging material, production speed, and durability requirements. In-mold labeling offers seamless integration and superior resistance to wear, making it ideal for high-volume manufacturing of durable goods. Pressure-sensitive labeling provides flexibility and ease of application, suitable for diverse shapes and smaller production runs.

In-mold labeling vs pressure-sensitive labeling Infographic

libmatt.com

libmatt.com