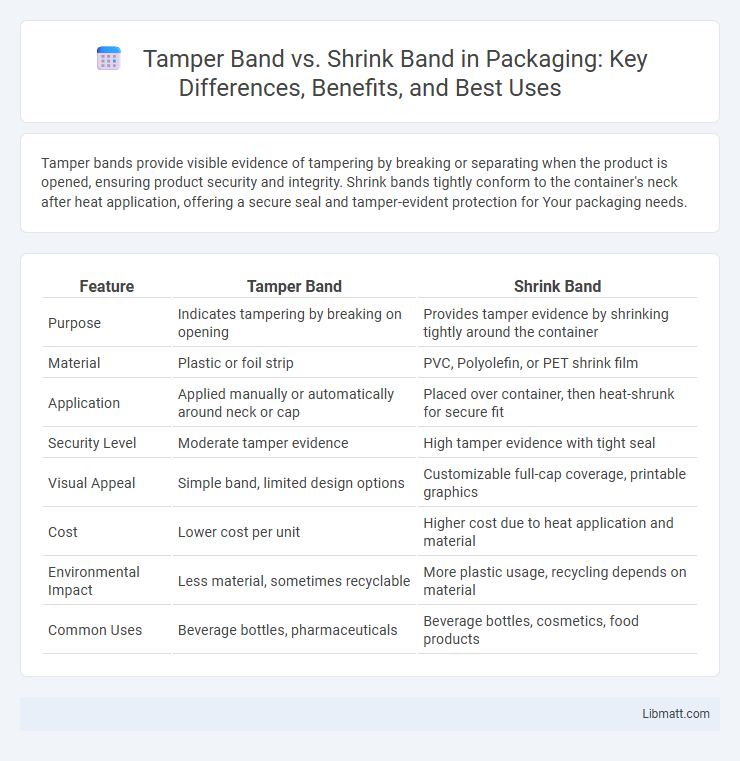

Tamper bands provide visible evidence of tampering by breaking or separating when the product is opened, ensuring product security and integrity. Shrink bands tightly conform to the container's neck after heat application, offering a secure seal and tamper-evident protection for Your packaging needs.

Table of Comparison

| Feature | Tamper Band | Shrink Band |

|---|---|---|

| Purpose | Indicates tampering by breaking on opening | Provides tamper evidence by shrinking tightly around the container |

| Material | Plastic or foil strip | PVC, Polyolefin, or PET shrink film |

| Application | Applied manually or automatically around neck or cap | Placed over container, then heat-shrunk for secure fit |

| Security Level | Moderate tamper evidence | High tamper evidence with tight seal |

| Visual Appeal | Simple band, limited design options | Customizable full-cap coverage, printable graphics |

| Cost | Lower cost per unit | Higher cost due to heat application and material |

| Environmental Impact | Less material, sometimes recyclable | More plastic usage, recycling depends on material |

| Common Uses | Beverage bottles, pharmaceuticals | Beverage bottles, cosmetics, food products |

Introduction to Tamper Bands and Shrink Bands

Tamper bands and shrink bands are security seals designed to protect product integrity and indicate unauthorized access. Tamper bands typically feature breakable rings or collars that detach upon opening, providing visible evidence of tampering. Shrink bands are plastic sleeves that conform tightly to containers after heat application, forming a sealed barrier that must be removed to access the product.

Key Differences Between Tamper Bands and Shrink Bands

Tamper bands and shrink bands both serve as security seals but differ in application and material. Tamper bands are typically made from plastic or metal and are designed to break or show visible damage when removed, providing a clear indication of unauthorized access. Shrink bands, made from heat-shrinkable plastic film, tightly conform to the container's neck when heated, offering a secure and tamper-evident seal that is difficult to reseal without detection.

Material Composition and Manufacturing Process

Tamper bands are typically made from materials like polyethylene or polypropylene, designed to break or tear upon opening, ensuring product integrity. Shrink bands consist primarily of PVC or polyolefin films, which shrink tightly around the container when exposed to heat during the manufacturing process. Your choice between these bands should consider the durability of materials and the specific sealing needs dictated by their distinct manufacturing techniques.

Application Methods for Tamper Bands vs Shrink Bands

Tamper bands are typically applied using manual or automated banding machines that securely fasten the bands around bottle necks or caps, ensuring visible evidence of tampering. Shrink bands require heat application via heat guns or tunnels, causing the band to conform tightly around the container, providing a tamper-evident seal. Your choice depends on the production line setup, with tamper bands offering quick application and shrink bands providing a tamper-resistant barrier through heat shrink technology.

Security Features: How Each Band Prevents Tampering

Tamper bands feature unique breakaway designs that provide visible evidence if someone tries to open or remove the seal, enhancing security by preventing unauthorized access. Shrink bands tighten securely around a container's cap or neck, creating a sealed barrier that must be removed or destroyed to access the contents, ensuring tamper evidence through physical deformation. Your choice between tamper bands and shrink bands should consider the level of tamper resistance and visual detection required for your security needs.

Cost Comparison: Tamper Bands Versus Shrink Bands

Tamper bands typically offer a more cost-effective solution due to lower material and application expenses compared to shrink bands, which require heat application equipment and often higher energy consumption. Shrink bands provide a tighter seal and enhanced tamper evidence but come with increased upfront and operational costs. Your choice depends on balancing budget constraints with security needs, as tamper bands minimize costs while shrink bands deliver superior protection.

Compatibility with Different Packaging Types

Tamper bands offer superior compatibility with a wide range of container neck sizes and shapes, fitting securely on bottles, jars, and tubs to ensure product integrity. Shrink bands require heat application to conform tightly around packaging, making them ideal for uniform bottle shapes but less adaptable to irregular surfaces. Your choice depends on the packaging design and the level of tamper-evidence required for your product line.

Regulatory Compliance and Industry Standards

Tamper bands and shrink bands play critical roles in regulatory compliance by providing visible evidence of product tampering, aligning with FDA and ISO standards for consumer safety and packaging integrity. Shrink bands comply with global packaging regulations by forming a tight seal that deters unauthorized access, while tamper bands offer clear breakage indicators essential for meeting pharmaceutical and food industry guidelines. Both band types support traceability and authentication protocols mandated by GMP (Good Manufacturing Practices) and prevent counterfeiting, reinforcing adherence to stringent industry standards.

Aesthetic and Branding Considerations

Tamper bands offer a clean, minimalistic look that enhances product aesthetics while clearly indicating if tampering has occurred, reinforcing customer trust in your brand. Shrink bands provide a sleek, form-fitting appearance that can be customized with branded graphics or colors to boost visual appeal and brand recognition. Choosing between tamper band vs shrink band depends on your packaging goals: tamper bands emphasize security and visible protection, whereas shrink bands excel in delivering a polished, professional look that supports your branding strategy.

Choosing the Right Band for Your Product

Choosing the right band for your product depends on the level of security and presentation you require. Tamper bands offer visible evidence of tampering through breakable seals, ideal for products needing high-security packaging. Shrink bands provide a tamper-evident, airtight seal that enhances shelf appeal while keeping contents secure from contamination and tampering.

Tamper band vs shrink band Infographic

libmatt.com

libmatt.com