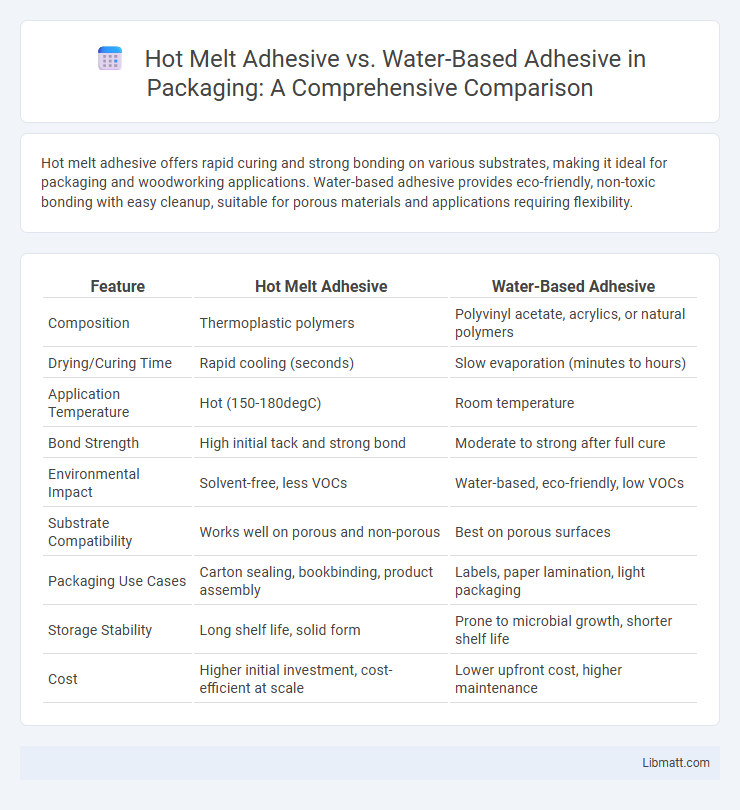

Hot melt adhesive offers rapid curing and strong bonding on various substrates, making it ideal for packaging and woodworking applications. Water-based adhesive provides eco-friendly, non-toxic bonding with easy cleanup, suitable for porous materials and applications requiring flexibility.

Table of Comparison

| Feature | Hot Melt Adhesive | Water-Based Adhesive |

|---|---|---|

| Composition | Thermoplastic polymers | Polyvinyl acetate, acrylics, or natural polymers |

| Drying/Curing Time | Rapid cooling (seconds) | Slow evaporation (minutes to hours) |

| Application Temperature | Hot (150-180degC) | Room temperature |

| Bond Strength | High initial tack and strong bond | Moderate to strong after full cure |

| Environmental Impact | Solvent-free, less VOCs | Water-based, eco-friendly, low VOCs |

| Substrate Compatibility | Works well on porous and non-porous | Best on porous surfaces |

| Packaging Use Cases | Carton sealing, bookbinding, product assembly | Labels, paper lamination, light packaging |

| Storage Stability | Long shelf life, solid form | Prone to microbial growth, shorter shelf life |

| Cost | Higher initial investment, cost-efficient at scale | Lower upfront cost, higher maintenance |

Introduction to Hot Melt Adhesives and Water-Based Adhesives

Hot melt adhesives are thermoplastic materials that melt upon heating and solidify upon cooling, offering fast bonding and strong adhesion for packaging, woodworking, and automotive applications. Water-based adhesives consist of polymer dispersions in water, known for their environmental friendliness, ease of cleanup, and versatility in paper, textile, and packaging industries. The choice between hot melt and water-based adhesives depends on substrate compatibility, drying time, and application requirements.

Chemical Composition and Formulation Differences

Hot melt adhesives primarily consist of thermoplastic polymers such as ethylene-vinyl acetate, polyolefins, or synthetic rubbers, which are melted and applied in a molten state without solvents or water. Water-based adhesives are formulated with polymers like polyvinyl acetate (PVA), acrylics, or natural rubber latex dispersed in water, relying on water evaporation for adhesion. The chemical composition differences influence drying mechanisms, application methods, and environmental impact, with hot melts offering rapid setting and water-based adhesives providing lower VOC emissions.

Application Methods and Equipment Requirements

Hot melt adhesives require specialized equipment such as heated applicators or glue guns to melt and apply the adhesive, making them ideal for fast-setting, high-strength bonds in industrial settings. Water-based adhesives typically use simpler application methods like spraying, brushing, or roll coating, requiring less complex and more cost-effective equipment suitable for porous materials and flexible manufacturing processes. Your choice of adhesive should consider the compatibility with your application equipment and production speed to optimize performance and efficiency.

Bonding Strength and Performance Comparison

Hot melt adhesives offer superior bonding strength and faster set times compared to water-based adhesives, making them ideal for high-performance applications requiring quick assembly and durable bonds. Water-based adhesives provide excellent flexibility and are more environmentally friendly but typically exhibit lower initial tack and slower curing times. Evaluating your project's requirements for bond durability and processing speed will determine the optimal adhesive choice.

Drying and Curing Times

Hot melt adhesives solidify quickly upon cooling, offering rapid setting and minimal downtime suitable for high-speed production lines. Water-based adhesives require longer drying and curing times due to evaporation of water, often necessitating extended air-drying or heat application stages. The choice between these adhesives depends on production speed requirements and the substrates involved, with hot melts favored for instant bonding and water-based options preferred for eco-friendly applications.

Environmental Impact and Sustainability

Hot melt adhesives generate minimal volatile organic compounds (VOCs) and have a low environmental footprint due to their solvent-free formulation and efficient curing process. Water-based adhesives rely on water as a carrier, reducing hazardous emissions but often require more energy for drying, impacting sustainability profiles. Choosing the right adhesive can enhance Your product's eco-friendliness by balancing VOC emissions, energy consumption, and recyclability.

Cost Analysis and Economic Considerations

Hot melt adhesives generally offer lower long-term costs due to faster curing times and reduced energy consumption compared to water-based adhesives, which require longer drying periods and more energy. The initial investment in hot melt equipment can be higher, but operational savings and increased production speed often offset this expense. Your choice should consider both the upfront costs and ongoing economic impact based on application volume and efficiency requirements.

Industry Applications and Suitability

Hot melt adhesives excel in packaging, woodworking, and automotive industries due to their fast bonding, high strength, and resistance to moisture. Water-based adhesives are preferred in paper, textiles, and eco-friendly product applications because of their low toxicity, ease of cleanup, and environmental compliance. Selecting between these adhesives depends on application requirements such as bonding speed, substrate type, and regulatory standards.

Health and Safety Considerations

Hot melt adhesives pose lower inhalation risks due to minimal volatile organic compound (VOC) emissions, but require careful handling to prevent burns from high application temperatures around 150-200degC. Water-based adhesives have reduced fire hazards and lower toxicity, but the presence of preservatives and solvents can cause respiratory irritation or allergic reactions in sensitive individuals. Proper ventilation and personal protective equipment (PPE) are essential for both types to minimize occupational health risks during application.

Choosing the Right Adhesive: Key Decision Factors

Choosing the right adhesive depends on application requirements such as drying time, bonding strength, and substrate compatibility. Hot melt adhesives offer rapid curing and strong bonds on non-porous materials, while water-based adhesives provide eco-friendly options with excellent adhesion to porous substrates and easy cleanup. Consider environmental conditions, material types, and production speed to optimize adhesive performance and cost-effectiveness.

Hot melt adhesive vs water-based adhesive Infographic

libmatt.com

libmatt.com