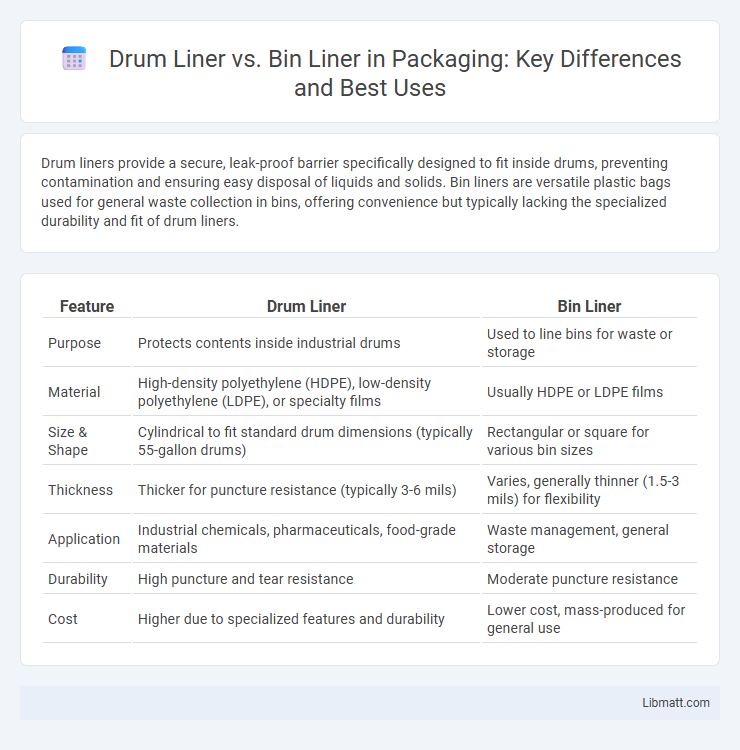

Drum liners provide a secure, leak-proof barrier specifically designed to fit inside drums, preventing contamination and ensuring easy disposal of liquids and solids. Bin liners are versatile plastic bags used for general waste collection in bins, offering convenience but typically lacking the specialized durability and fit of drum liners.

Table of Comparison

| Feature | Drum Liner | Bin Liner |

|---|---|---|

| Purpose | Protects contents inside industrial drums | Used to line bins for waste or storage |

| Material | High-density polyethylene (HDPE), low-density polyethylene (LDPE), or specialty films | Usually HDPE or LDPE films |

| Size & Shape | Cylindrical to fit standard drum dimensions (typically 55-gallon drums) | Rectangular or square for various bin sizes |

| Thickness | Thicker for puncture resistance (typically 3-6 mils) | Varies, generally thinner (1.5-3 mils) for flexibility |

| Application | Industrial chemicals, pharmaceuticals, food-grade materials | Waste management, general storage |

| Durability | High puncture and tear resistance | Moderate puncture resistance |

| Cost | Higher due to specialized features and durability | Lower cost, mass-produced for general use |

Introduction to Drum Liners and Bin Liners

Drum liners are heavy-duty bags designed to fit the interior of large industrial drums, providing protection against contamination and facilitating easy disposal of hazardous or non-hazardous materials. Bin liners, also known as trash bags or garbage liners, are flexible plastic liners used to line waste bins or containers, preventing leaks and maintaining cleanliness in residential, commercial, or industrial settings. Both serve as essential containment solutions but differ primarily in size, thickness, and application based on the type of container and waste management requirements.

Key Differences Between Drum Liners and Bin Liners

Drum liners are specifically designed to fit inside industrial drums, providing a secure and leak-proof barrier for liquids or granular materials, while bin liners are larger and more flexible bags intended to line waste or storage bins to contain solid refuse and debris. Drum liners typically have thicker, more durable materials to handle heavy-duty use and prevent punctures, whereas bin liners prioritize volume capacity and may vary in thickness depending on the application, such as household or commercial waste. The key differences lie in size, material strength, and intended use, with drum liners suited for chemical or hazardous contents and bin liners optimized for general waste containment.

Materials Used in Drum Liners vs Bin Liners

Drum liners are typically made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE), providing strong puncture resistance and chemical compatibility suitable for industrial waste containment. Bin liners often use similar polyethylene materials but may incorporate recycled content or thinner gauges to balance durability with cost-effectiveness for everyday waste disposal. Your choice between drum liners and bin liners should consider the material strength and application requirements to ensure optimal protection and environmental compliance.

Size and Capacity Comparison

Drum liners typically range from 30 to 110 gallons, designed to fit industrial drums with tight seals for secure containment. Bin liners come in broader sizes, often from 10 to 96 gallons, tailored for household or commercial waste bins with various thickness options for strength. The capacity difference aligns with their use cases: drum liners handle larger, heavy-duty waste, while bin liners suit smaller, everyday trash disposal.

Typical Applications for Drum Liners

Drum liners are widely used in industrial and manufacturing settings to protect steel drums during the storage and transportation of hazardous chemicals, powders, and bulk solids. They prevent contamination, moisture ingress, and facilitate easy discharge of contents, making them essential in pharmaceutical, food processing, and chemical industries. Typical applications include safely containing corrosive materials, minimizing product waste, and enhancing compliance with environmental regulations.

Common Uses for Bin Liners

Bin liners are commonly used in household waste management, commercial garbage disposal, and industrial waste containment to prevent contamination and facilitate easy waste removal. They are designed to fit various bin sizes, making them ideal for kitchens, offices, and outdoor trash bins. Their durability and moisture resistance ensure efficient handling of wet and dry waste, unlike drum liners which are typically used for hazardous or bulk material containment in drums.

Durability and Strength: Drum Liner vs Bin Liner

Drum liners offer superior durability and strength compared to bin liners, designed to withstand heavy loads and sharp edges typical in industrial settings. Their thicker gauge polyethylene material resists punctures, tears, and chemical corrosion, ensuring enhanced protection and longevity. Choosing the right liner depends on your application's weight and durability requirements, with drum liners providing reliable containment for demanding environments.

Environmental Impact and Sustainability

Drum liners and bin liners differ in environmental impact, with biodegradable and compostable options available for both that reduce landfill waste and lower carbon footprints. Drum liners typically offer heavier-duty protection, potentially extending product life and reducing material waste through durability. Choosing recycled or reusable liners enhances sustainability, supporting circular economy principles by minimizing resource extraction and promoting waste reduction.

Cost Considerations and Budgeting

Drum liners generally cost more than bin liners due to their thicker, more durable materials designed for heavy-duty industrial use, impacting budget allocation for large-scale waste management. Bin liners offer a more economical option for everyday, lighter waste disposal, making them suitable for offices and households where cost efficiency is crucial. Budget planning should consider liner size, material strength, and waste type to optimize expenses without compromising functionality.

How to Choose the Right Liner for Your Needs

Selecting the right liner depends on the container size and application requirements; drum liners are designed for cylindrical drums typically used for hazardous or liquid waste, offering superior chemical resistance and durability. Bin liners are versatile for various bin sizes, suited for solid waste and general refuse, available in different thicknesses and materials tailored to specific waste types. Assess the waste type, container dimensions, and disposal regulations to ensure optimal liner performance and environmental compliance.

Drum liner vs bin liner Infographic

libmatt.com

libmatt.com