Monomaterial packaging offers superior recyclability due to its single material composition, simplifying sorting and processing in recycling facilities. Composite packaging combines multiple materials to enhance barrier properties and durability, but this complexity often hinders efficient recycling and increases environmental impact.

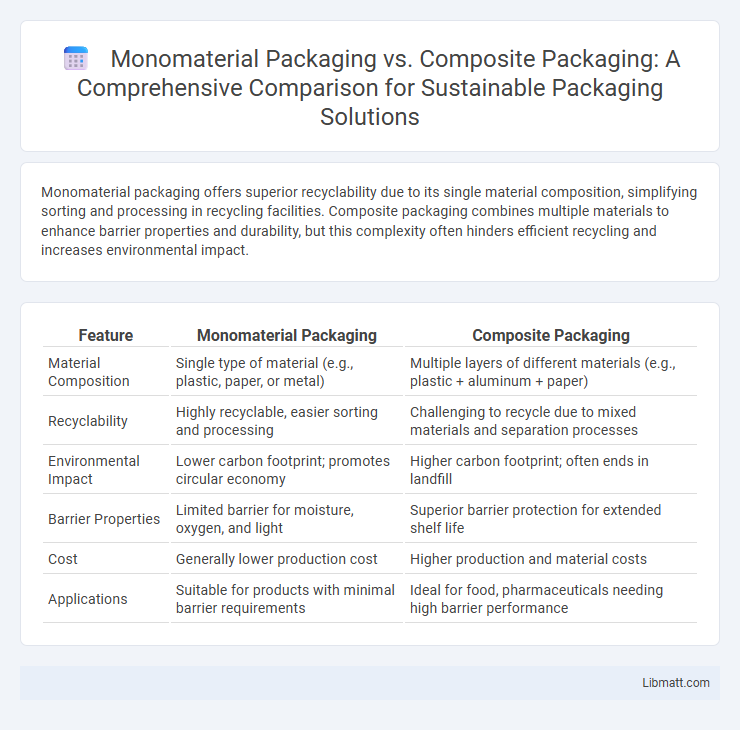

Table of Comparison

| Feature | Monomaterial Packaging | Composite Packaging |

|---|---|---|

| Material Composition | Single type of material (e.g., plastic, paper, or metal) | Multiple layers of different materials (e.g., plastic + aluminum + paper) |

| Recyclability | Highly recyclable, easier sorting and processing | Challenging to recycle due to mixed materials and separation processes |

| Environmental Impact | Lower carbon footprint; promotes circular economy | Higher carbon footprint; often ends in landfill |

| Barrier Properties | Limited barrier for moisture, oxygen, and light | Superior barrier protection for extended shelf life |

| Cost | Generally lower production cost | Higher production and material costs |

| Applications | Suitable for products with minimal barrier requirements | Ideal for food, pharmaceuticals needing high barrier performance |

Introduction to Packaging Types

Monomaterial packaging consists of a single type of material, such as polyethylene or polypropylene, enabling easier recycling and reduced environmental impact compared to composite packaging. Composite packaging combines multiple layers of different materials, like plastic, aluminum, and paper, providing enhanced barrier properties but complicating recycling processes. The choice between monomaterial and composite packaging depends on balancing product protection requirements with sustainability goals in supply chain operations.

Defining Monomaterial Packaging

Monomaterial packaging consists entirely of a single type of material, such as polyethylene or polypropylene, which enhances recyclability by simplifying the sorting and recycling process. Unlike composite packaging, which combines multiple materials like plastic, aluminum, and paper, monomaterial packaging reduces contamination and improves efficiency in recycling facilities. Your choice of monomaterial packaging supports sustainable waste management by enabling higher recovery rates and lowering environmental impact.

Understanding Composite Packaging

Composite packaging combines multiple materials such as plastic, paper, and aluminum to enhance product protection and shelf life, often making recycling more complex due to the difficulty of separating these materials. In contrast, monomaterial packaging uses a single material type, improving recyclability and reducing environmental impact by simplifying waste processing. Understanding composite packaging helps you evaluate its benefits in product preservation against its challenges in sustainable disposal and recycling.

Material Composition and Structure

Monomaterial packaging consists of a single type of material such as polyethylene or polypropylene, allowing for easier recycling due to its uniform composition and simplified structure. Composite packaging combines multiple layers of different materials like plastic, aluminum, and paper, creating a barrier with enhanced protection but complicating the recycling process due to the difficulty of separating materials. The structural complexity of composite packaging improves product shelf life and durability but poses significant challenges for sustainable waste management compared to monomaterial options.

Environmental Impact Comparison

Monomaterial packaging significantly reduces environmental impact due to its easier recyclability and lower contamination rates in recycling streams compared to composite packaging, which complicates processing and often ends up in landfills. Recycling monomaterial packaging conserves resources and reduces greenhouse gas emissions by facilitating higher recycling yield and less waste generation. Your choice of packaging can drive sustainability efforts by prioritizing monomaterial options that support circular economy principles and minimize ecological footprints.

Recycling and End-of-Life Solutions

Monomaterial packaging offers superior recyclability compared to composite packaging due to its uniform material composition, allowing for efficient sorting and processing in recycling facilities. Composite packaging, often made from multiple bonded layers like plastic, aluminum, and paper, poses challenges in recycling because these layers must be separated before processing, leading to higher costs and lower recovery rates. You can enhance your product's sustainability impact by choosing monomaterial packaging, which supports circular economy initiatives and simplifies end-of-life waste management.

Performance and Barrier Properties

Monomaterial packaging offers superior recyclability due to its uniform material composition but may have limitations in barrier properties compared to composite packaging, which combines multiple layers to enhance protection against moisture, oxygen, and light. Composite packaging delivers exceptional performance in preserving product freshness and extending shelf life by leveraging synergistic barrier properties of different materials. Your choice depends on balancing environmental impact with the required barrier effectiveness for your specific product.

Cost Implications and Economic Factors

Monomaterial packaging generally offers lower recycling costs and streamlined processing due to its uniform material composition, which reduces sorting complexity and enhances circular economy potential. Composite packaging incurs higher production expenses because of its multi-layer structure involving diverse materials, leading to increased waste management and recycling challenges that elevate overall costs. Economic factors favor monomaterial solutions by promoting material recovery efficiency and reducing environmental fees, while composite packaging often results in higher operational expenditures and limited end-of-life value.

Industry Adoption and Market Trends

Monomaterial packaging has seen rapid adoption across the food and beverage industry due to its recyclability and alignment with circular economy goals, with companies like Nestle and Unilever committing to 100% recyclable packaging by 2025. Composite packaging, although offering superior barrier properties and product protection, faces challenges in market growth due to recycling complexities and limited infrastructure. Market trends indicate a strong shift towards monomaterial solutions driven by regulatory pressures, consumer demand for sustainability, and innovations in polymer technology enhancing performance and cost-efficiency.

Future Outlook: Innovations in Packaging

Monomaterial packaging is gaining traction due to its recyclability and ease of sorting, driven by circular economy goals and stringent environmental regulations. Innovations such as bio-based monomaterials and enhanced barrier properties are improving performance, enabling wider application in food and consumer goods. Composite packaging continues to advance with smart technologies like embedded sensors and multilayer recyclability solutions, but efforts are increasingly focused on simplifying material composition to meet sustainability targets.

Monomaterial packaging vs composite packaging Infographic

libmatt.com

libmatt.com