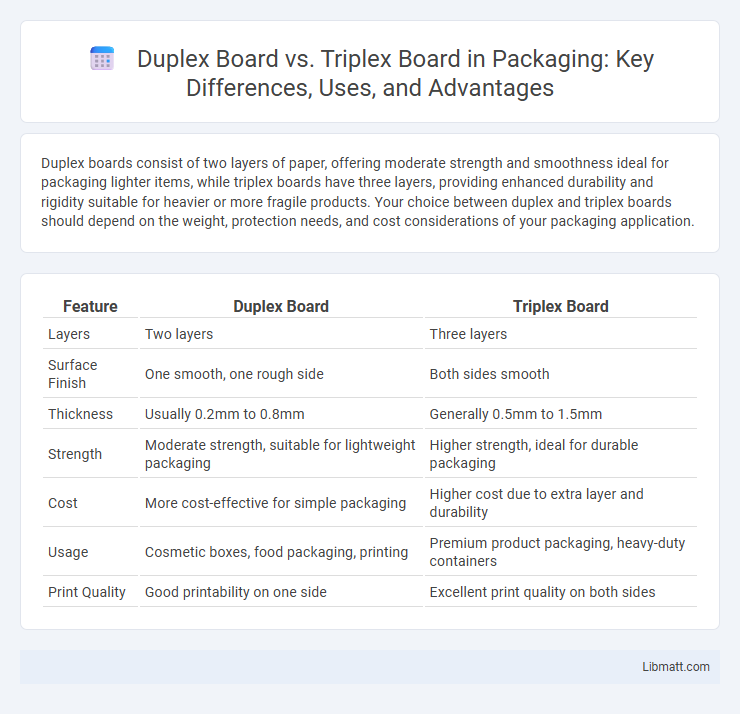

Duplex boards consist of two layers of paper, offering moderate strength and smoothness ideal for packaging lighter items, while triplex boards have three layers, providing enhanced durability and rigidity suitable for heavier or more fragile products. Your choice between duplex and triplex boards should depend on the weight, protection needs, and cost considerations of your packaging application.

Table of Comparison

| Feature | Duplex Board | Triplex Board |

|---|---|---|

| Layers | Two layers | Three layers |

| Surface Finish | One smooth, one rough side | Both sides smooth |

| Thickness | Usually 0.2mm to 0.8mm | Generally 0.5mm to 1.5mm |

| Strength | Moderate strength, suitable for lightweight packaging | Higher strength, ideal for durable packaging |

| Cost | More cost-effective for simple packaging | Higher cost due to extra layer and durability |

| Usage | Cosmetic boxes, food packaging, printing | Premium product packaging, heavy-duty containers |

| Print Quality | Good printability on one side | Excellent print quality on both sides |

Introduction to Duplex and Triplex Boards

Duplex board consists of two layers of paperboard, providing a smooth and printable surface ideal for packaging and cartons, while maintaining rigidity and durability. Triplex board features three layers, enhancing strength and stiffness, making it suitable for heavier products and more demanding applications. Both boards differ in thickness, weight, and durability, with duplex offering lighter protection and triplex supporting greater structural integrity.

Composition and Structure Differences

Duplex board consists of two layers of paper laminated together, featuring a coated top layer for print quality and a rough uncoated backside for writing or supporting purposes. Triplex board comprises three layers, including an additional middle layer that enhances thickness, rigidity, and strength compared to duplex board. This structural difference makes triplex board more suitable for applications requiring higher durability and sturdier packaging solutions.

Manufacturing Process Overview

Duplex board is manufactured by laminating two layers of paper, typically combining a bleached white top ply with a recycled brown back ply, resulting in a smooth surface ideal for printing. Triplex board involves three layers, often including a thick middle layer made from recycled fibers sandwiched between two outer plies of stronger paper to enhance rigidity and strength. The triplex manufacturing process incorporates additional pressing and drying steps to achieve greater thickness and durability compared to the simpler, faster duplex board production.

Key Physical Properties Comparison

Duplex board features a smooth, white surface on one side and a rough, brown surface on the other, offering moderate stiffness and good printability, making it suitable for packaging lightweight products. Triplex board consists of three layers of pulp with a white top layer and a brown backing, providing higher stiffness, improved durability, and better resistance to bending and compression compared to duplex board. You should choose triplex board for applications requiring enhanced structural strength, while duplex board works well for less demanding packaging needs.

Applications of Duplex Board

Duplex board is primarily used for packaging applications that require a smooth surface for printing and moderate strength, such as food packaging, cartons, and cosmetic boxes. Its semi-bleached coating on one side makes it ideal for high-quality graphics and product presentation. In contrast, triplex board, being thicker and sturdier, is suited for heavier packaging needs and industrial uses where durability is critical.

Applications of Triplex Board

Triplex board is widely used in packaging applications that require higher strength and durability compared to duplex board, such as heavy-duty cartons, industrial packaging, and boxes for electronics or appliances. Its triple-layer construction provides excellent rigidity and impact resistance, making it ideal for shipping and storage solutions that protect fragile or heavy items. Your choice of triplex board ensures enhanced protection and stability for demanding packaging needs.

Strength and Durability Analysis

Duplex board features a single layer coated for enhanced strength and moderate durability, making it ideal for lightweight packaging and printing applications. Triplex board consists of three layers, offering superior strength and increased durability suited for heavy-duty packaging and protection. Your choice between duplex and triplex boards depends on the required load-bearing capacity and resistance to wear during transit or storage.

Cost and Economic Considerations

Duplex board typically costs less than triplex board due to its simpler two-layer construction, making it an economical choice for packaging and printing applications with moderate durability requirements. Triplex board, with its three-layer composition, provides enhanced strength and rigidity but comes at a higher price, justified in situations demanding superior performance and protection. Businesses must weigh triplex board's increased cost against potential savings from reduced product damage and improved brand perception to determine the most cost-effective option.

Environmental Impact and Sustainability

Duplex board is generally more eco-friendly due to its simpler composition and higher recyclability, consisting of two layers of paperboard made from recycled fibers and renewable sources. Triplex board, with its three layers including a thicker middle layer often containing virgin fibers, tends to have a larger environmental footprint but offers greater strength and durability for packaging needs. Your choice between duplex and triplex boards can influence sustainability goals, favoring duplex for lower carbon emissions and easier recycling.

Choosing the Right Board for Your Needs

Duplex board offers a smooth, dull finish suitable for printing and packaging that requires high-quality graphics, while triplex board, with its thicker and more rigid structure, provides superior durability and strength for heavier or more protective packaging solutions. Your choice depends on the balance between aesthetic appeal and structural integrity needed for your product, with duplex ideal for lightweight items and triplex better for products requiring extra sturdiness. Consider the specific application, weight, and protection level desired to ensure you select the right board that meets your packaging or printing requirements efficiently.

Duplex board vs triplex board Infographic

libmatt.com

libmatt.com