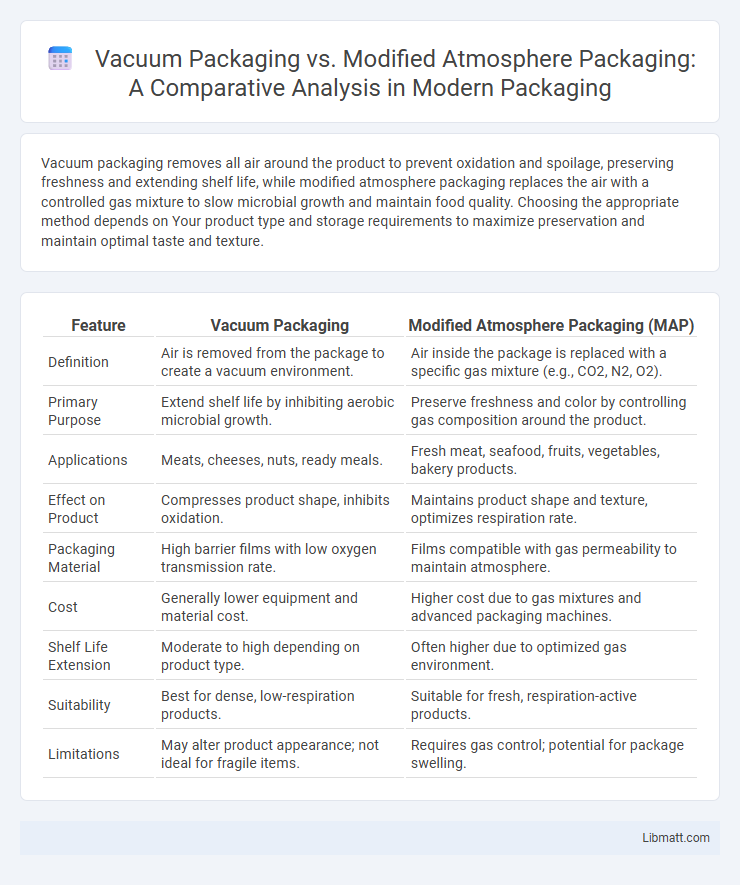

Vacuum packaging removes all air around the product to prevent oxidation and spoilage, preserving freshness and extending shelf life, while modified atmosphere packaging replaces the air with a controlled gas mixture to slow microbial growth and maintain food quality. Choosing the appropriate method depends on Your product type and storage requirements to maximize preservation and maintain optimal taste and texture.

Table of Comparison

| Feature | Vacuum Packaging | Modified Atmosphere Packaging (MAP) |

|---|---|---|

| Definition | Air is removed from the package to create a vacuum environment. | Air inside the package is replaced with a specific gas mixture (e.g., CO2, N2, O2). |

| Primary Purpose | Extend shelf life by inhibiting aerobic microbial growth. | Preserve freshness and color by controlling gas composition around the product. |

| Applications | Meats, cheeses, nuts, ready meals. | Fresh meat, seafood, fruits, vegetables, bakery products. |

| Effect on Product | Compresses product shape, inhibits oxidation. | Maintains product shape and texture, optimizes respiration rate. |

| Packaging Material | High barrier films with low oxygen transmission rate. | Films compatible with gas permeability to maintain atmosphere. |

| Cost | Generally lower equipment and material cost. | Higher cost due to gas mixtures and advanced packaging machines. |

| Shelf Life Extension | Moderate to high depending on product type. | Often higher due to optimized gas environment. |

| Suitability | Best for dense, low-respiration products. | Suitable for fresh, respiration-active products. |

| Limitations | May alter product appearance; not ideal for fragile items. | Requires gas control; potential for package swelling. |

Introduction to Food Packaging Technologies

Vacuum packaging removes air to inhibit microbial growth and extend shelf life, making it ideal for delicate foods like meats and cheeses. Modified atmosphere packaging (MAP) replaces the air inside a package with a specific gas mixture, optimizing oxygen, carbon dioxide, and nitrogen levels to preserve freshness and color in fresh produce and meats. Choosing the right food packaging technology enhances Your product's quality, safety, and marketability.

What is Vacuum Packaging?

Vacuum packaging is a preservation method that removes air from the package before sealing, significantly reducing oxygen levels to slow microbial growth and oxidation. This technology is widely used in the food industry for meats, cheeses, and processed goods to extend shelf life and maintain product freshness. By creating an anaerobic environment, vacuum packaging helps retain moisture, flavor, and texture while preventing spoilage and contamination.

Defining Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) involves altering the composition of gases surrounding a product, typically fresh food, within a sealed package to extend shelf life and maintain quality. Unlike vacuum packaging, which removes air entirely, MAP replaces oxygen with gases like nitrogen and carbon dioxide to slow oxidation and microbial growth. Understanding MAP helps you choose the best packaging method for preserving freshness and preventing spoilage.

Key Differences Between Vacuum Packaging and MAP

Vacuum packaging removes air entirely from the package, creating a tight seal that inhibits aerobic bacterial growth and oxidation, while Modified Atmosphere Packaging (MAP) replaces the air inside the package with a specific gas mixture, often nitrogen, carbon dioxide, or oxygen, to extend product shelf life and maintain color and freshness. Vacuum packaging is ideal for products that are sensitive to oxygen and require an anaerobic environment, whereas MAP is better suited for fresh produce and meats that benefit from controlled gas compositions to slow spoilage. The choice between vacuum packaging and MAP depends on the product type, desired shelf life, and preservation goals related to maintaining texture, flavor, and microbial safety.

Shelf Life Extension: Vacuum vs MAP

Vacuum packaging extends shelf life by removing oxygen, significantly slowing microbial growth and oxidation, ideal for meats and cheeses with a shelf life increase of 2 to 3 times. Modified Atmosphere Packaging (MAP) replaces oxygen with gases like nitrogen or carbon dioxide, optimizing the atmosphere to preserve freshness and extend shelf life up to 5 times longer than conventional packaging. Your choice depends on product type and desired shelf life, as MAP offers more control over gas composition for sensitive fresh produce and bakery items.

Impact on Food Quality and Freshness

Vacuum packaging removes air to inhibit microbial growth and oxidation, effectively preserving the freshness and extending the shelf life of foods like meats and cheeses by maintaining texture and flavor. Modified atmosphere packaging (MAP) replaces the air with specific gas blends (such as nitrogen and carbon dioxide) to slow spoilage and retain the color, aroma, and nutritional quality of fresh produce and deli items. Your choice between these methods will affect how well the product maintains its sensory attributes and overall food quality during storage.

Cost Comparison: Vacuum Packaging vs MAP

Vacuum packaging generally incurs lower initial equipment and material costs compared to modified atmosphere packaging (MAP), making it more accessible for small to medium-sized businesses. However, MAP offers extended shelf life and improved product quality, which can lead to reduced food waste and potentially lower overall expenses over time. The choice between vacuum packaging and MAP often depends on balancing upfront investment with long-term savings related to product preservation and marketability.

Suitable Applications and Product Types

Vacuum packaging is ideal for solid, non-perishable foods such as cured meats, cheese, and nuts, where oxygen removal extends shelf life and prevents spoilage. Modified atmosphere packaging (MAP) suits fresh produce, deli meats, and bakery products by replacing oxygen with gases like nitrogen or carbon dioxide to maintain color, texture, and freshness. Both methods optimize preservation but differ in application based on product sensitivity to oxygen and required shelf life.

Sustainability and Environmental Considerations

Vacuum packaging significantly reduces oxygen exposure, extending shelf life and lowering food waste, which contributes to sustainability, although it often relies on non-biodegradable plastic films. Modified atmosphere packaging (MAP) uses gas mixtures to inhibit microbial growth, also extending freshness but typically involves complex multilayer materials that challenge recyclability. Innovations in bio-based and recyclable films for both vacuum and MAP formats are crucial to minimizing environmental impact and enhancing the eco-friendliness of food packaging solutions.

Choosing the Right Packaging Method for Your Needs

Vacuum packaging removes air to extend shelf life by inhibiting microbial growth, ideal for products that are moisture-sensitive or need airtight sealing. Modified atmosphere packaging (MAP) replaces the air with a gas mix, such as nitrogen or carbon dioxide, to maintain freshness and color, making it suitable for fresh produce and meats. Your choice depends on product type, shelf-life requirements, and storage conditions to ensure optimal quality and safety.

Vacuum packaging vs modified atmosphere packaging Infographic

libmatt.com

libmatt.com