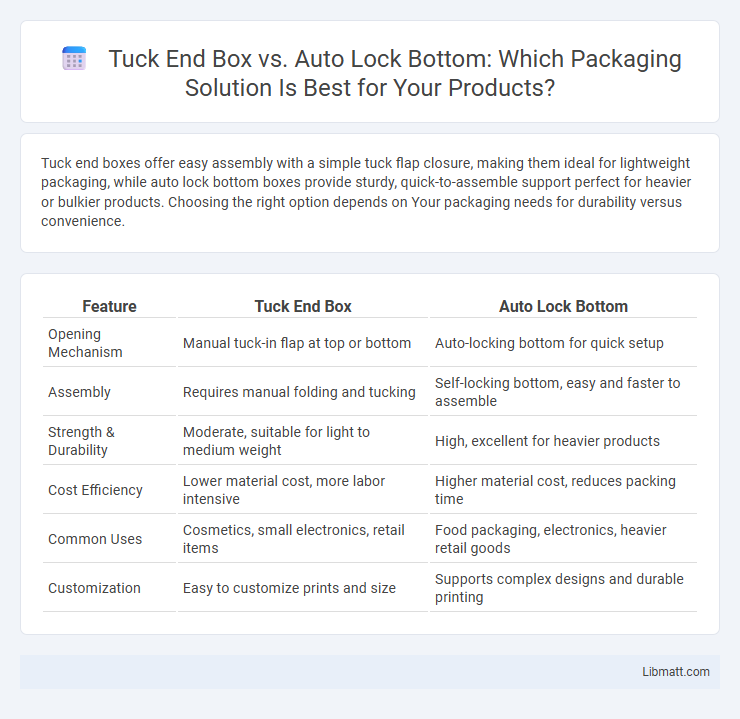

Tuck end boxes offer easy assembly with a simple tuck flap closure, making them ideal for lightweight packaging, while auto lock bottom boxes provide sturdy, quick-to-assemble support perfect for heavier or bulkier products. Choosing the right option depends on Your packaging needs for durability versus convenience.

Table of Comparison

| Feature | Tuck End Box | Auto Lock Bottom |

|---|---|---|

| Opening Mechanism | Manual tuck-in flap at top or bottom | Auto-locking bottom for quick setup |

| Assembly | Requires manual folding and tucking | Self-locking bottom, easy and faster to assemble |

| Strength & Durability | Moderate, suitable for light to medium weight | High, excellent for heavier products |

| Cost Efficiency | Lower material cost, more labor intensive | Higher material cost, reduces packing time |

| Common Uses | Cosmetics, small electronics, retail items | Food packaging, electronics, heavier retail goods |

| Customization | Easy to customize prints and size | Supports complex designs and durable printing |

Introduction to Packaging Solutions

Tuck end boxes and auto lock bottom boxes are popular packaging solutions designed to enhance product protection and ease of assembly in various industries. Tuck end boxes feature flaps that tuck into the box body, providing a secure closure ideal for lightweight items, while auto lock bottom boxes have a pre-glued bottom that automatically locks into place for added strength and faster setup. Both packaging types optimize functionality, improve shelf appeal, and support efficient logistics by balancing durability with cost-effective manufacturing.

What is a Tuck End Box?

A Tuck End Box features flaps on one or both ends that tuck into the main structure, providing secure closure and easy access. Its simple design enhances packaging efficiency, making it ideal for lightweight products and retail displays. You can choose this box style for customizable branding and quick assembly without the need for additional adhesives or tapes.

What is an Auto Lock Bottom Box?

An Auto Lock Bottom Box features a pre-glued locking mechanism at the base, allowing for quick and secure assembly without the need for additional adhesive or tape. This design provides enhanced structural stability and is ideal for heavier or bulkier products. Compared to a Tuck End Box, which requires manual folding and securing, the Auto Lock Bottom Box streamlines packaging efficiency and offers superior load-bearing capacity.

Structural Differences: Tuck End vs Auto Lock Bottom

Tuck end boxes feature flaps on both ends that tuck into the box body, providing simple closure and easy access, ideal for lightweight products. Auto lock bottom boxes have a pre-glued bottom that automatically locks into place when assembled, offering enhanced strength and stability for heavier items. The key structural difference lies in the bottom closure mechanism, with auto lock bottoms providing a more secure, rigid base compared to the flexible tuck end design.

Assembly and Ease of Use

Tuck end boxes are designed with a simple fold-in flap system that allows for quick hand assembly without the need for adhesives, making them ideal for manual packing processes requiring flexibility. Auto lock bottom boxes feature a pre-glued, self-locking bottom that securely holds the contents with minimal effort, streamlining your packing operations and reducing setup time. Your choice between these box types should consider the balance between ease of assembly and the level of protection required for your product.

Strength and Load-Bearing Capacity

Tuck end boxes offer moderate strength and are primarily designed for lightweight products with easy access and frequent opening. Auto lock bottom boxes provide superior load-bearing capacity due to their secure locking mechanism, making them ideal for heavier or bulkier items requiring added durability during transport. The auto lock bottom design ensures enhanced structural integrity and reduces the risk of bottom failure under substantial weight.

Cost Comparison

Tuck end boxes generally cost less due to simpler manufacturing and reduced material usage, making them ideal for budget-conscious packaging needs. Auto lock bottom boxes, while more expensive, offer enhanced durability and faster assembly, which can reduce labor costs and improve efficiency in high-volume production. Your choice depends on balancing initial cost savings with long-term operational benefits.

Suitability for Various Products

Tuck end boxes offer versatile packaging suitable for lightweight to moderately heavy products such as cosmetics, pharmaceuticals, and small electronics, ensuring easy access and secure closure. Auto lock bottom boxes provide superior strength and stability, ideal for heavier items like food products, cosmetics with multiple components, and retail goods that require a sturdy base. Choosing the right option depends on your product's weight, protection needs, and ease of assembly for optimal packaging performance.

Customization and Printing Options

Tuck end boxes offer extensive customization options with customizable flaps and five sides available for high-quality printing, making them ideal for branding and detailed product information. Auto lock bottom boxes provide sturdy construction with quick assembly, while still allowing vibrant full-color printing on all panels for eye-catching shelf appeal. Your choice depends on balancing the need for intricate design flexibility versus convenient functionality and durability.

Choosing the Right Box for Your Business

Tuck end boxes provide easy assembly and are ideal for lightweight products and quick packaging needs, while auto lock bottom boxes offer enhanced strength and stability for heavier or bulkier items. Evaluating product weight, shipping requirements, and production speed helps determine the most efficient and cost-effective packaging solution. Businesses prioritizing durability and secure closure often benefit from auto lock bottom designs, whereas those focusing on speed and simplicity may prefer tuck end boxes.

Tuck end box vs auto lock bottom Infographic

libmatt.com

libmatt.com