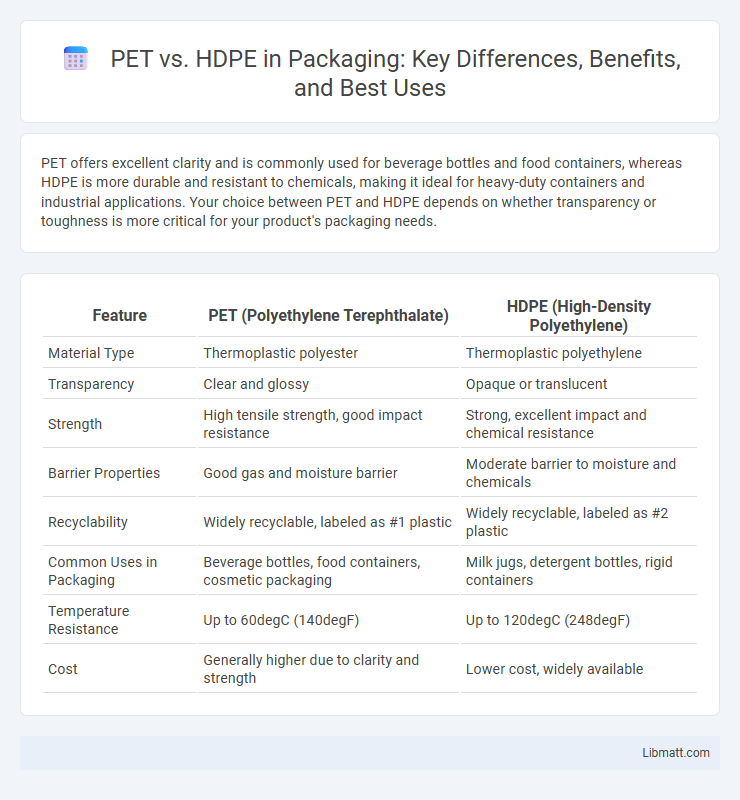

PET offers excellent clarity and is commonly used for beverage bottles and food containers, whereas HDPE is more durable and resistant to chemicals, making it ideal for heavy-duty containers and industrial applications. Your choice between PET and HDPE depends on whether transparency or toughness is more critical for your product's packaging needs.

Table of Comparison

| Feature | PET (Polyethylene Terephthalate) | HDPE (High-Density Polyethylene) |

|---|---|---|

| Material Type | Thermoplastic polyester | Thermoplastic polyethylene |

| Transparency | Clear and glossy | Opaque or translucent |

| Strength | High tensile strength, good impact resistance | Strong, excellent impact and chemical resistance |

| Barrier Properties | Good gas and moisture barrier | Moderate barrier to moisture and chemicals |

| Recyclability | Widely recyclable, labeled as #1 plastic | Widely recyclable, labeled as #2 plastic |

| Common Uses in Packaging | Beverage bottles, food containers, cosmetic packaging | Milk jugs, detergent bottles, rigid containers |

| Temperature Resistance | Up to 60degC (140degF) | Up to 120degC (248degF) |

| Cost | Generally higher due to clarity and strength | Lower cost, widely available |

Introduction to PET and HDPE

PET (Polyethylene Terephthalate) and HDPE (High-Density Polyethylene) are two widely used thermoplastic polymers in packaging and manufacturing industries. PET is known for its clarity, strength, and barrier properties, making it ideal for beverage bottles and food containers, while HDPE offers excellent chemical resistance, durability, and flexibility, commonly used for milk jugs, detergent bottles, and piping. Both materials differ significantly in structure and applications, influencing their recycling processes and environmental impact.

Chemical Structure and Composition

PET (Polyethylene Terephthalate) is a polyester formed from the polymerization of ethylene glycol and terephthalic acid, featuring ester functional groups that contribute to its rigidity and clarity. HDPE (High-Density Polyethylene) consists of long chains of ethylene monomers arranged in a linear and highly crystalline structure, resulting in strong intermolecular forces and high tensile strength. The chemical composition of PET includes aromatic rings and ester linkages, whereas HDPE is composed solely of saturated hydrocarbon chains, influencing their physical properties and applications.

Common Uses and Applications

PET (Polyethylene Terephthalate) is widely used for packaging beverages, food containers, and synthetic fibers due to its excellent strength, clarity, and gas barrier properties. HDPE (High-Density Polyethylene) is commonly utilized in manufacturing detergent bottles, milk jugs, and piping because of its high durability, chemical resistance, and impact strength. Both polymers are essential in packaging industries but serve distinct roles based on their physical characteristics and application requirements.

Physical Properties Comparison

PET (Polyethylene Terephthalate) offers higher tensile strength and better impact resistance compared to HDPE (High-Density Polyethylene), making it ideal for applications requiring durability and clarity. HDPE excels in chemical resistance and flexibility, with a lower density that provides lighter weight and better insulation properties. Your choice between PET and HDPE should consider these physical property differences to match specific performance needs in packaging or product design.

Environmental Impact and Recycling

PET (Polyethylene Terephthalate) has a higher recycling rate than HDPE (High-Density Polyethylene) due to widespread acceptance in curbside programs and established markets for recycled PET. HDPE is more resistant to degradation and can be recycled into durable goods like piping and plastic lumber, often resulting in a longer lifecycle for recycled products. Your choice between PET and HDPE can significantly influence environmental impact, as PET tends to have a larger carbon footprint during production but offers better recyclability infrastructure.

Durability and Longevity

PET offers excellent durability with strong resistance to impact and moisture, making it ideal for packaging that requires a long shelf life. HDPE provides superior chemical resistance and toughness, allowing it to withstand harsh conditions and prolonged outdoor exposure without degrading. Your choice between PET and HDPE should consider the specific environment and use case to ensure optimal longevity of the material.

Cost and Economic Considerations

PET generally incurs higher production costs than HDPE due to its more complex manufacturing process and greater energy requirements. HDPE offers a more cost-effective solution for large-scale applications, with lower raw material prices and faster processing times that boost economic efficiency. Evaluating your budget constraints alongside the intended application will help determine which plastic aligns better with your economic goals.

Safety and Food Contact Suitability

PET (Polyethylene Terephthalate) and HDPE (High-Density Polyethylene) are both widely used for food packaging due to their safety and FDA approval for direct food contact. PET offers excellent barrier properties against moisture and gases, ensuring longer shelf life and maintaining food freshness, making it ideal for beverages and perishable goods. HDPE is highly resistant to chemicals and impact, safe for dairy and juice containers, with your choice depending on the specific food product requirements and storage conditions.

Market Trends and Consumer Preferences

PET dominates the beverage packaging market due to its clarity, lightweight nature, and recyclability, driving strong consumer preference for bottled water and soft drinks. HDPE is favored for household and industrial containers because of its durability, chemical resistance, and cost-effectiveness, aligning with market trends toward sustainable packaging solutions. Your choice between PET and HDPE should consider product type, environmental impact, and evolving consumer demand for recyclable and eco-friendly materials.

Choosing Between PET and HDPE

Choosing between PET and HDPE depends on the specific application requirements such as barrier properties, durability, and environmental impact. PET offers excellent clarity and superior gas and moisture barrier, ideal for beverages and food packaging, whereas HDPE provides higher chemical resistance, flexibility, and is commonly used for containers, bottles, and industrial applications. Both plastics are recyclable, but HDPE generally has a lower environmental footprint due to easier recycling processes and higher energy recovery rates.

PET vs HDPE Infographic

libmatt.com

libmatt.com