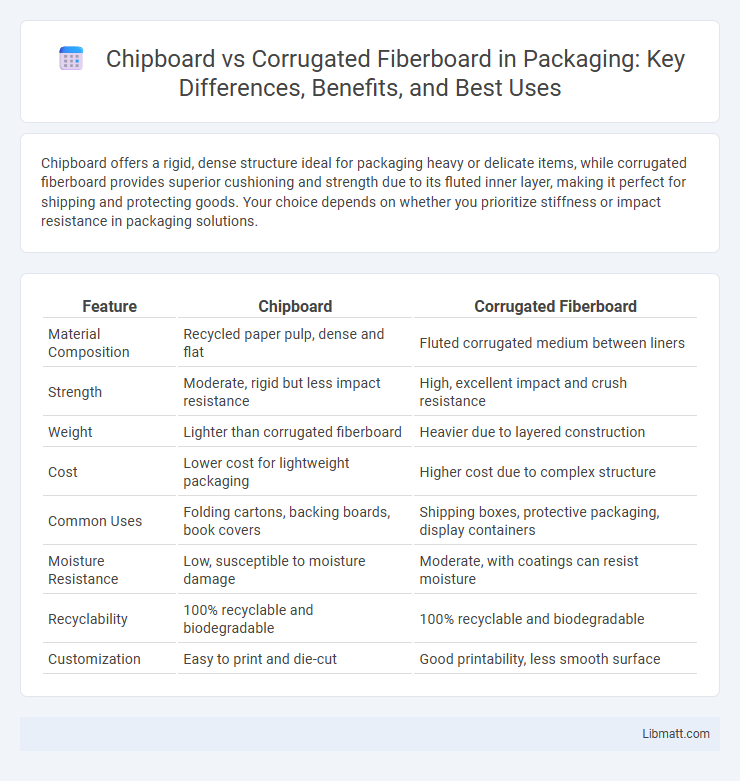

Chipboard offers a rigid, dense structure ideal for packaging heavy or delicate items, while corrugated fiberboard provides superior cushioning and strength due to its fluted inner layer, making it perfect for shipping and protecting goods. Your choice depends on whether you prioritize stiffness or impact resistance in packaging solutions.

Table of Comparison

| Feature | Chipboard | Corrugated Fiberboard |

|---|---|---|

| Material Composition | Recycled paper pulp, dense and flat | Fluted corrugated medium between liners |

| Strength | Moderate, rigid but less impact resistance | High, excellent impact and crush resistance |

| Weight | Lighter than corrugated fiberboard | Heavier due to layered construction |

| Cost | Lower cost for lightweight packaging | Higher cost due to complex structure |

| Common Uses | Folding cartons, backing boards, book covers | Shipping boxes, protective packaging, display containers |

| Moisture Resistance | Low, susceptible to moisture damage | Moderate, with coatings can resist moisture |

| Recyclability | 100% recyclable and biodegradable | 100% recyclable and biodegradable |

| Customization | Easy to print and die-cut | Good printability, less smooth surface |

Introduction to Chipboard and Corrugated Fiberboard

Chipboard, a rigid paper product made from reclaimed paper and wood fibers, offers excellent durability and is commonly used for packaging and backing applications. Corrugated fiberboard consists of a fluted corrugated sheet sandwiched between two liners, providing superior strength and cushioning ideal for shipping boxes and protective packaging. Understanding the distinct structural properties of chipboard and corrugated fiberboard helps you select the best material for specific packaging needs.

What is Chipboard?

Chipboard is a rigid, engineered wood product made from compressed wood chips, sawdust, and resin binders, commonly used in packaging, furniture, and construction. It offers a dense, solid structure compared to corrugated fiberboard, which consists of a fluted corrugated sheet sandwiched between liners and is known for its lightweight and cushioning properties. Understanding the differences in material composition and strength between chipboard and corrugated fiberboard helps you select the optimal packaging or construction solution.

What is Corrugated Fiberboard?

Corrugated fiberboard consists of a fluted corrugated sheet and one or two flat linerboards, providing strength and cushioning ideal for shipping and packaging. It offers excellent durability, impact resistance, and is lightweight, making it suitable for protecting fragile items during transit. This material is widely used in the packaging industry due to its recyclability and cost-effectiveness compared to solid chipboard.

Key Differences in Material Composition

Chipboard is made from recycled wood pulp and paperboard pressed into solid sheets, providing rigidity and a smooth surface, while corrugated fiberboard consists of a fluted corrugated sheet sandwiched between two flat linerboards, offering enhanced strength and cushioning. The composition of chipboard is dense and uniform, making it ideal for lightweight packaging and backing, whereas corrugated fiberboard's layered structure absorbs shocks, making it suitable for shipping and protective packaging. Understanding these material differences helps you choose the right option for your packaging needs based on durability and protection requirements.

Strength and Durability Comparison

Chipboard offers moderate strength suitable for lightweight packaging, but corrugated fiberboard provides superior durability due to its multi-layered construction with fluted inner liners that absorb shocks and resist punctures. The rigidity of corrugated fiberboard makes it ideal for protecting heavier, fragile items during transit, outperforming chipboard in impact resistance and load-bearing capacity. For applications requiring enhanced protection and structural integrity, corrugated fiberboard is the preferred choice over chipboard.

Applications and Common Uses

Chipboard is commonly used in packaging for lightweight products, book covers, and furniture backing due to its rigidity and smooth surface. Corrugated fiberboard excels in shipping boxes and protective packaging, offering superior cushioning and impact resistance from its fluted layer. Both materials serve distinct roles in packaging depending on strength requirements and product protection needs.

Environmental Impact and Sustainability

Chipboard and corrugated fiberboard differ significantly in environmental impact and sustainability; corrugated fiberboard is often made from recycled materials and is widely recyclable, reducing waste in landfills. Chipboard, while also recyclable, tends to have a higher environmental footprint due to the use of adhesives and coatings that can hinder recyclability and increase processing emissions. Choosing corrugated fiberboard for your packaging needs supports a more sustainable choice by promoting circularity and minimizing ecological harm.

Cost and Affordability Analysis

Chipboard generally offers a lower cost solution compared to corrugated fiberboard due to its simpler manufacturing process and lighter material composition. Corrugated fiberboard, with its layered fluted structure, provides superior strength and durability but typically comes at a higher price, impacting overall affordability. For budget-sensitive packaging, chipboard is often the preferred option, whereas corrugated fiberboard is selected for applications requiring enhanced protection despite increased cost.

Design and Customization Options

Chipboard offers versatile design and customization options with smooth surfaces ideal for high-quality printing, die-cutting, and embossing, making it suitable for premium packaging and retail displays. Corrugated fiberboard provides robust structural integrity with customizable fluting profiles and multiple wall constructions, allowing tailored protection and strength for shipping and handling. Both materials support diverse finishing techniques, but chipboard excels in aesthetic appeal while corrugated fiberboard prioritizes durability and impact resistance.

Choosing the Right Material: Chipboard vs Corrugated Fiberboard

Chipboard offers a dense, rigid structure ideal for packaging small, lightweight items and provides excellent printing surface for branding. Corrugated fiberboard features a fluted corrugated sheet sandwiched between liners, delivering superior strength, cushioning, and durability for shipping heavy or fragile goods. When choosing the right material, consider your product's weight, protection needs, and presentation requirements to ensure your packaging performs effectively.

Chipboard vs corrugated fiberboard Infographic

libmatt.com

libmatt.com