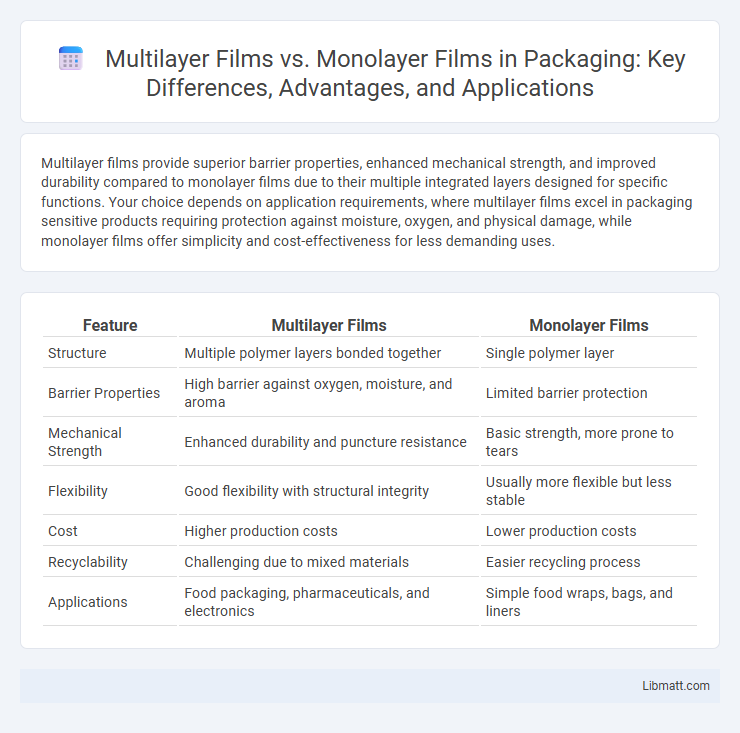

Multilayer films provide superior barrier properties, enhanced mechanical strength, and improved durability compared to monolayer films due to their multiple integrated layers designed for specific functions. Your choice depends on application requirements, where multilayer films excel in packaging sensitive products requiring protection against moisture, oxygen, and physical damage, while monolayer films offer simplicity and cost-effectiveness for less demanding uses.

Table of Comparison

| Feature | Multilayer Films | Monolayer Films |

|---|---|---|

| Structure | Multiple polymer layers bonded together | Single polymer layer |

| Barrier Properties | High barrier against oxygen, moisture, and aroma | Limited barrier protection |

| Mechanical Strength | Enhanced durability and puncture resistance | Basic strength, more prone to tears |

| Flexibility | Good flexibility with structural integrity | Usually more flexible but less stable |

| Cost | Higher production costs | Lower production costs |

| Recyclability | Challenging due to mixed materials | Easier recycling process |

| Applications | Food packaging, pharmaceuticals, and electronics | Simple food wraps, bags, and liners |

Introduction to Multilayer and Monolayer Films

Multilayer films consist of two or more layers of distinct materials laminated to enhance barrier properties, mechanical strength, and functionality in packaging and electronics. Monolayer films are single-layered structures offering simplicity, lower cost, and ease of recycling but often lack the advanced protective qualities of multilayers. The choice between multilayer and monolayer films depends on application-specific requirements such as durability, moisture resistance, and environmental impact.

Material Composition and Structure

Multilayer films consist of multiple stacked polymer layers, each tailored to provide specific barrier properties such as oxygen, moisture, or UV resistance, enhancing overall film performance compared to monolayer films made from a single polymer type. The layered structure of multilayer films allows for the combination of materials like polyethylene, polypropylene, and ethylene-vinyl alcohol (EVOH), optimizing mechanical strength, clarity, and flexibility. Your choice between multilayer and monolayer films depends on the required balance of protection, durability, and cost-efficiency in the application.

Manufacturing Processes Compared

Multilayer films are produced using complex co-extrusion or lamination techniques, combining multiple polymer layers to achieve enhanced barrier, mechanical, and optical properties. Monolayer films, in contrast, are manufactured through simpler single-layer extrusion or casting methods, offering cost-effectiveness but limited functionality. Understanding these manufacturing processes allows you to select the appropriate film type based on performance requirements and budget constraints.

Mechanical and Barrier Properties

Multilayer films exhibit superior mechanical strength and enhanced barrier properties compared to monolayer films due to their composite structure that combines different polymer layers, optimizing flexibility, tensile strength, and resistance to puncture. The multilayer configuration allows for tailored permeability to oxygen, moisture, and gases, significantly extending the shelf life of packaged goods by preventing contamination and degradation. Monolayer films generally have limited barrier performance and reduced mechanical durability, making them less suitable for applications requiring prolonged protection and mechanical resistance.

Cost Analysis: Multilayer vs Monolayer

Multilayer films generally incur higher production costs due to the complexity of combining multiple polymer layers and the advanced technology required, compared to monolayer films which are simpler and cheaper to manufacture. However, multilayer films often provide superior performance in barrier properties, extending product shelf life and potentially reducing overall packaging costs and waste. Your choice between multilayer and monolayer films should weigh upfront material expenses against long-term savings and product preservation benefits.

Applications in Various Industries

Multilayer films offer enhanced barrier properties, making them ideal for food packaging, pharmaceuticals, and electronics industries where protection against moisture, oxygen, and contaminants is crucial. Monolayer films, with their simplicity and cost-effectiveness, are widely used in applications such as agricultural mulch films and basic packaging where less stringent barrier requirements exist. Your choice between multilayer and monolayer films depends on the specific industry demands for durability, protection, and cost efficiency.

Environmental Impact and Recyclability

Multilayer films, composed of multiple polymer layers, present significant challenges for recycling due to the difficulty in separating distinct materials, which often leads to increased landfill waste and environmental pollution. Monolayer films, typically made from a single type of polymer like polyethylene, offer better recyclability and lower environmental impact because they can be processed more efficiently through standard recycling streams. The environmental footprint of multilayer films is generally higher due to their complex manufacturing process and limited recyclability, whereas monolayer films support circular economy principles by facilitating material recovery and reuse.

Performance in Packaging Solutions

Multilayer films in packaging solutions provide superior barrier properties, enhanced mechanical strength, and improved flexibility compared to monolayer films, making them ideal for preserving food freshness and extending shelf life. These films combine multiple materials like polyethylene, polyester, and nylon, optimizing gas, moisture, and aroma resistance, which monolayer films typically lack due to their single-material composition. Consequently, multilayer films offer advanced protection in diverse packaging applications such as vacuum-sealed products, modified atmosphere packaging, and high-barrier pouches.

Market Trends and Innovations

The multilayer films market is experiencing significant growth due to increasing demand for enhanced barrier properties and durability in packaging, especially in food and pharmaceutical industries. Innovations such as bio-based multilayer films and advanced co-extrusion technologies are driving sustainability and cost-effectiveness, attracting investments from major players like Dow and BASF. In contrast, monolayer films maintain relevance in applications requiring simplicity and recyclability, with emerging developments focusing on mono-material solutions to improve environmental impact.

Choosing the Right Film for Your Needs

Multilayer films offer superior barrier properties, combining different materials to enhance durability, moisture resistance, and oxygen control, making them ideal for complex packaging needs. Monolayer films provide simplicity and cost-effectiveness, suitable for applications with minimal barrier requirements or short-term use. Your choice depends on balancing performance demands, budget constraints, and the specific environmental conditions your packaged products will encounter.

Multilayer films vs monolayer films Infographic

libmatt.com

libmatt.com