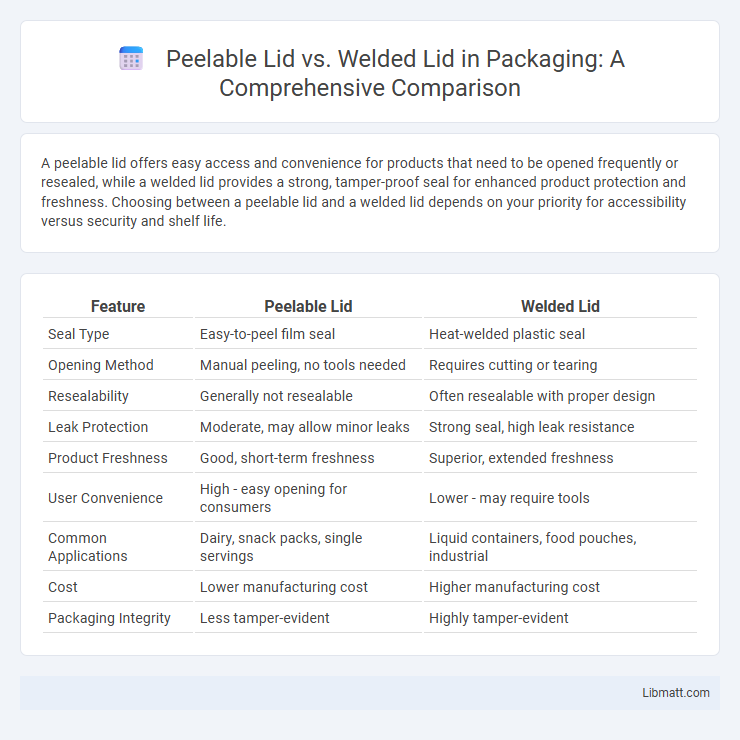

A peelable lid offers easy access and convenience for products that need to be opened frequently or resealed, while a welded lid provides a strong, tamper-proof seal for enhanced product protection and freshness. Choosing between a peelable lid and a welded lid depends on your priority for accessibility versus security and shelf life.

Table of Comparison

| Feature | Peelable Lid | Welded Lid |

|---|---|---|

| Seal Type | Easy-to-peel film seal | Heat-welded plastic seal |

| Opening Method | Manual peeling, no tools needed | Requires cutting or tearing |

| Resealability | Generally not resealable | Often resealable with proper design |

| Leak Protection | Moderate, may allow minor leaks | Strong seal, high leak resistance |

| Product Freshness | Good, short-term freshness | Superior, extended freshness |

| User Convenience | High - easy opening for consumers | Lower - may require tools |

| Common Applications | Dairy, snack packs, single servings | Liquid containers, food pouches, industrial |

| Cost | Lower manufacturing cost | Higher manufacturing cost |

| Packaging Integrity | Less tamper-evident | Highly tamper-evident |

Introduction to Peelable and Welded Lids

Peelable lids offer convenient, easy access to product contents by allowing consumers to remove the seal without tools, preserving freshness and ensuring tamper evidence. Welded lids are heat-sealed directly to containers, providing a strong, airtight bond for enhanced durability and product protection during transportation and storage. Your choice between peelable and welded lids depends on balancing convenience with security and shelf-life requirements.

Key Differences Between Peelable and Welded Lids

Peelable lids offer easy opening without tools, providing convenience and preserving product freshness through an airtight seal, while welded lids create a permanent, tamper-evident seal ideal for long-term storage and safety. Peelable lids are often used for single-serving or ready-to-eat products, making them customer-friendly, whereas welded lids are common in industrial or bulk packaging where durability and security are priorities. Choosing between peelable and welded lids depends on your product's usage, shelf life requirements, and consumer experience goals.

Material Composition and Construction

Peelable lids are typically made from multi-layered laminated films combining aluminum foil with heat-sealable polymers, allowing easy removal without tools. Welded lids consist of rigid materials such as aluminum or metal alloys fused directly to container rims through ultrasonic or induction welding, ensuring a hermetic seal. Your choice depends on whether you prioritize convenience in opening or maximum barrier protection and seal integrity.

Applications in Food and Beverage Packaging

Peelable lids provide convenient, tamper-evident access for ready-to-eat foods and single-serve beverage containers, enhancing user experience and maintaining freshness. Welded lids offer superior hermetic sealing ideal for long shelf-life products like dairy, juices, and sauces, ensuring microbiological safety and preventing contamination. Your choice between peelable and welded lids impacts product preservation, consumer convenience, and packaging integrity in the food and beverage industry.

Ease of Use: Consumer Convenience

Peelable lids offer superior ease of use by allowing consumers to open packaging effortlessly without the need for additional tools, enhancing overall convenience. In contrast, welded lids provide a more secure seal but can be challenging to open, potentially causing frustration or requiring scissors to access the product. Your choice between peelable and welded lids directly impacts the consumer experience, prioritizing accessibility or product security based on your packaging needs.

Seal Integrity and Product Safety

Peelable lids provide user-friendly access with moderate seal integrity, making them suitable for products requiring easy opening but shorter shelf life. Welded lids offer superior seal strength and enhanced product safety by forming a tamper-evident barrier that prevents contamination and extends shelf stability. Choosing between peelable and welded lids depends on balancing consumer convenience with stringent safety and preservation requirements.

Impact on Shelf Life and Freshness

Peelable lids provide an effective barrier against air and moisture, preserving product freshness while allowing easy access without compromising seal integrity. Welded lids offer a stronger, tamper-evident seal that enhances shelf life by minimizing contamination risks and preventing oxidation. Choosing between peelable and welded lids depends on balancing ease of use with the required level of protection to maintain optimal freshness during storage.

Cost Comparison: Production and Materials

Peelable lids typically incur higher material costs due to specialized films and coatings but reduce labor expenses with faster, easier application processes. Welded lids involve lower material costs using basic aluminum or plastic but require more energy and time-intensive machinery for secure sealing. Overall, peelable lids balance higher material expenses with production efficiency, while welded lids favor cheaper materials but increased operational costs.

Sustainability and Environmental Considerations

Peelable lids offer enhanced recyclability by allowing easy separation from containers, reducing contamination in recycling streams compared to welded lids that are often fused and more challenging to recycle. The production of peelable lids generally requires less energy and material, resulting in a lower carbon footprint than welded lids which demand higher heat and energy for sealing. Choosing peelable lids aligns with sustainability goals by promoting circular economy principles and minimizing environmental impact through improved waste management.

Choosing the Right Lid: Factors to Consider

Choosing the right lid depends on factors such as product freshness, tamper evidence, and ease of use. Peelable lids offer convenience and easy access, ideal for single-use or resealable packaging, while welded lids provide a stronger seal for enhanced durability and protection against leaks or contamination. Assess your product's shelf life, user experience, and packaging integrity needs to determine whether a peelable or welded lid best suits your packaging requirements.

Peelable lid vs welded lid Infographic

libmatt.com

libmatt.com