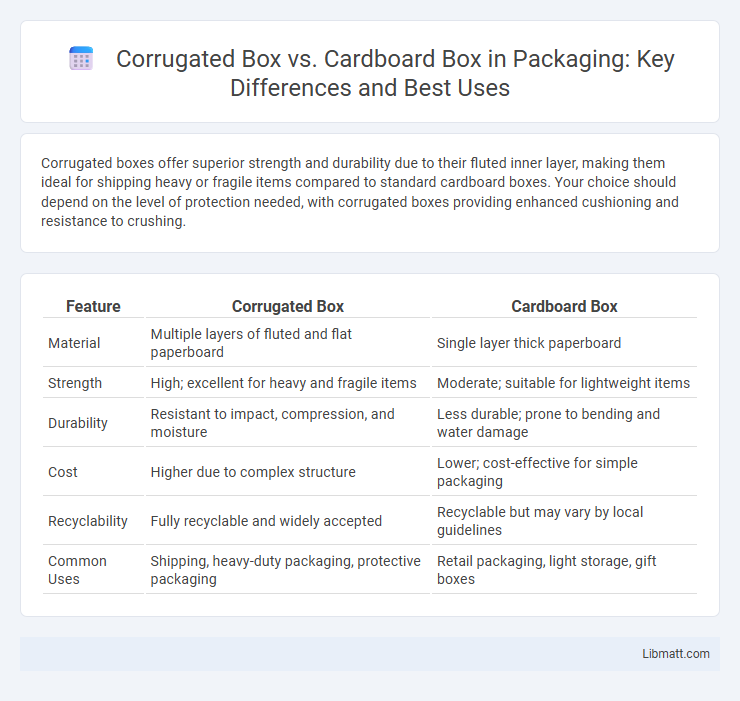

Corrugated boxes offer superior strength and durability due to their fluted inner layer, making them ideal for shipping heavy or fragile items compared to standard cardboard boxes. Your choice should depend on the level of protection needed, with corrugated boxes providing enhanced cushioning and resistance to crushing.

Table of Comparison

| Feature | Corrugated Box | Cardboard Box |

|---|---|---|

| Material | Multiple layers of fluted and flat paperboard | Single layer thick paperboard |

| Strength | High; excellent for heavy and fragile items | Moderate; suitable for lightweight items |

| Durability | Resistant to impact, compression, and moisture | Less durable; prone to bending and water damage |

| Cost | Higher due to complex structure | Lower; cost-effective for simple packaging |

| Recyclability | Fully recyclable and widely accepted | Recyclable but may vary by local guidelines |

| Common Uses | Shipping, heavy-duty packaging, protective packaging | Retail packaging, light storage, gift boxes |

Understanding Corrugated Boxes: Key Features

Corrugated boxes consist of three layers: an inside liner, an outside liner, and a fluted corrugated medium that provides superior strength and cushioning compared to standard cardboard boxes. These boxes offer enhanced durability, moisture resistance, and impact protection, making them ideal for shipping and storing fragile or heavy items. Understanding the structure and benefits of corrugated boxes helps you select the best packaging solution for your products.

What Defines a Cardboard Box?

A cardboard box is defined by its material composition, typically made from paper-based fiberboard, offering lightweight and general-purpose packaging solutions. Unlike corrugated boxes, cardboard boxes lack the fluted middle layer that provides enhanced strength and cushioning. Your choice depends on the required durability and protection level for your specific items.

Material Composition: Corrugated vs Cardboard

Corrugated boxes consist of three layers: an inner liner, outer liner, and a fluted corrugated medium sandwiched between them, providing enhanced strength and durability. Cardboard boxes are made from a single layer of thick paperboard, which is less sturdy and more prone to bending or crushing under weight. Your choice depends on the need for protection, with corrugated boxes ideal for shipping fragile or heavy items due to their reinforced material composition.

Structural Strength and Durability Comparison

Corrugated boxes feature a fluted corrugated sheet sandwiched between two linerboards, providing enhanced structural strength and superior durability compared to regular cardboard boxes, which are typically made from a single layer of paperboard. This design allows corrugated boxes to withstand heavier loads, resist crushing, and absorb impacts during shipping, ensuring better protection for Your items. Cardboard boxes, while lighter and often cheaper, offer less resilience under pressure and are more prone to damage and deformation.

Common Uses for Corrugated Boxes

Corrugated boxes are widely used for shipping and packaging heavy or fragile items due to their strong fluted inner layer, which provides excellent cushioning and protection. Common industries utilizing corrugated boxes include e-commerce, food distribution, and electronics, where durability and impact resistance are critical. Your products remain secure during transit, making these boxes ideal for both storage and transportation.

Typical Applications of Cardboard Boxes

Cardboard boxes are commonly used for lightweight item packaging, retail product displays, and short-term storage due to their affordability and ease of customization. They are ideal for protecting items like clothing, books, and consumer electronics during local shipping or in-store handling. Your choice of cardboard boxes is well-suited for scenarios requiring simple protection and cost-effective packaging solutions.

Cost Differences: Which Box is More Affordable?

Corrugated boxes typically cost more than cardboard boxes due to their multi-layered construction that provides greater durability and protection. Cardboard boxes, often made from a single layer of paperboard, are more affordable and suitable for lightweight, less fragile items. When considering packaging budgets, cardboard boxes offer cost savings but may not provide the same strength and impact resistance as corrugated boxes.

Environmental Impact: Sustainability and Recycling

Corrugated boxes offer a higher degree of sustainability due to their eco-friendly production process, which primarily uses recycled paper fibers and can be recycled multiple times without significant loss of quality. Cardboard boxes, often made from thinner, less durable paperboard, may have lower recycling potential and typically contribute to more waste in landfills. Choosing corrugated boxes supports environmental efforts by reducing deforestation and lowering carbon footprints through efficient recycling systems.

Choosing the Right Box for Shipping Needs

Corrugated boxes provide enhanced durability and protection with their multi-layered construction, making them ideal for shipping heavy or fragile items. Cardboard boxes, typically single-layered, suit lightweight or less delicate shipments where cost-efficiency is a priority. Consider your shipping needs, including product weight and fragility, to ensure your package arrives safely using the appropriate box type.

Corrugated vs Cardboard: Final Recommendations

Corrugated boxes offer superior durability and cushioning due to their multi-layered fluted structure, making them ideal for shipping fragile or heavy items. Cardboard boxes, typically made from a single sheet of paperboard, are best suited for lightweight packaging and short-term storage. For businesses requiring robust protection and cost-effective transport solutions, corrugated boxes are the recommended choice, while cardboard boxes serve well for retail display and light-duty uses.

Corrugated box vs cardboard box Infographic

libmatt.com

libmatt.com