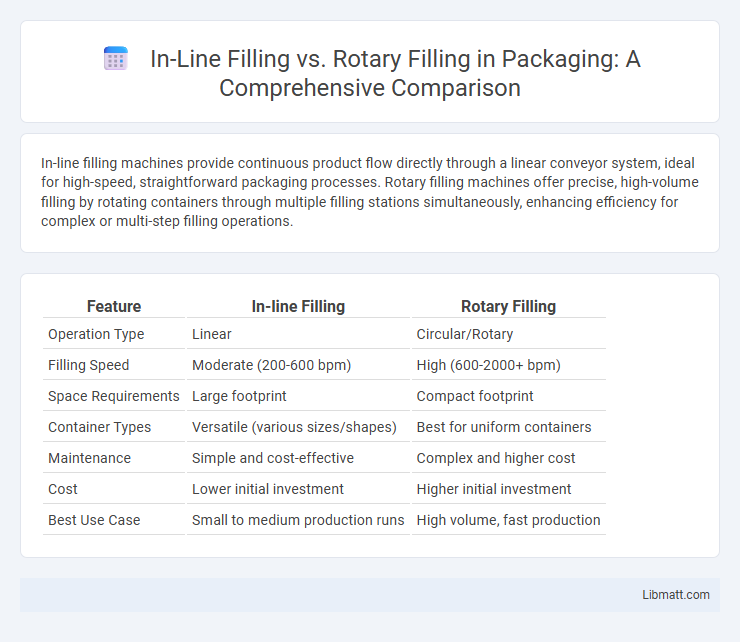

In-line filling machines provide continuous product flow directly through a linear conveyor system, ideal for high-speed, straightforward packaging processes. Rotary filling machines offer precise, high-volume filling by rotating containers through multiple filling stations simultaneously, enhancing efficiency for complex or multi-step filling operations.

Table of Comparison

| Feature | In-line Filling | Rotary Filling |

|---|---|---|

| Operation Type | Linear | Circular/Rotary |

| Filling Speed | Moderate (200-600 bpm) | High (600-2000+ bpm) |

| Space Requirements | Large footprint | Compact footprint |

| Container Types | Versatile (various sizes/shapes) | Best for uniform containers |

| Maintenance | Simple and cost-effective | Complex and higher cost |

| Cost | Lower initial investment | Higher initial investment |

| Best Use Case | Small to medium production runs | High volume, fast production |

Introduction to Liquid Filling Technologies

In-line filling and rotary filling are two advanced liquid filling technologies designed to maximize efficiency and accuracy in packaging processes. In-line filling systems operate with containers moving in a single, continuous line, ideal for moderate production volumes and diverse container sizes. Rotary filling machines use a rotating carousel to fill multiple containers simultaneously, making them the preferred choice for high-speed, large-scale liquid packaging operations, ensuring your production line maintains consistent throughput and precision.

Overview of In-Line Filling Systems

In-line filling systems streamline production by integrating filling directly within the conveyor line, maximizing efficiency for small to medium batch sizes. These systems are ideal for products requiring precise volume control and quick changeovers, often used in food, beverage, and pharmaceutical industries. Your manufacturing process benefits from reduced footprint and simplified automation with in-line filling solutions compared to rotary filling machines.

Understanding Rotary Filling Systems

Rotary filling systems employ a rotating turret to fill multiple containers simultaneously, significantly increasing production efficiency compared to in-line filling systems, which fill containers sequentially on a straight conveyor belt. These systems are ideal for high-speed packaging operations in industries like pharmaceuticals and beverages due to their compact design and ability to handle various container sizes with precision. Understanding the mechanics and advantages of rotary filling is crucial for optimizing manufacturing productivity and reducing downtime.

Key Differences Between In-Line and Rotary Fillers

In-line fillers operate with a linear conveyor system where bottles pass sequentially through one filling station, providing precise control for low to medium production volumes. Rotary fillers use a rotating platform with multiple filling heads, enabling high-speed, continuous filling ideal for large-scale operations. Your choice depends on production speed requirements, space availability, and the complexity of the filling process.

Speed and Production Capacity Comparison

In-line filling machines offer moderate speed suitable for small to medium production runs, typically achieving up to 200 bottles per minute depending on product viscosity and container size. Rotary filling systems excel in high-speed operations, often surpassing 1,000 bottles per minute due to their continuous circular motion and multiple filling heads, making them ideal for large-scale production. Choosing the right filling method depends on your required production capacity and desired throughput efficiency.

Accuracy and Consistency in Filling

In-line filling machines provide precise and consistent volume control by filling containers individually as they pass through a linear conveyor, minimizing variation and product waste. Rotary filling systems enhance accuracy by using multiple filling heads that simultaneously fill containers, ensuring uniform fill levels and high-speed production without compromising consistency. Both technologies optimize accuracy through advanced sensors and servo controls, but rotary filling excels in high-volume applications requiring rapid throughput with consistent fill quality.

Space and Footprint Requirements

In-line filling machines require a linear arrangement, which can demand extensive floor space but offers straightforward workflow integration for high-speed production. Rotary filling systems feature a compact circular design, significantly reducing the machine footprint and optimizing space utilization in facilities with limited area. Choosing between in-line and rotary filling depends on production volume goals and available manufacturing floor space.

Cost Considerations and Return on Investment

In-line filling machines typically offer lower initial costs and simpler maintenance, making them suitable for small to medium production runs with faster return on investment. Rotary filling systems involve higher upfront capital due to complex engineering but provide superior speed and efficiency for large-scale operations, resulting in greater long-term cost savings. Evaluating production volume, product type, and operational priorities is essential for maximizing ROI when choosing between in-line and rotary filling technologies.

Application Suitability Across Industries

In-line filling systems excel in industries with smaller production volumes or product variety, such as pharmaceuticals, cosmetics, and specialty foods, offering flexibility and easy changeover. Rotary filling machines are ideal for high-speed, high-volume operations in sectors like beverages, dairy, and automotive lubricants, where rapid production and consistent accuracy are critical. Your choice between in-line and rotary filling depends on production scale, product type, and factory layout requirements.

Choosing the Right Filling Solution for Your Business

Choosing the right filling solution depends on factors like production volume, product type, and space availability. In-line filling machines offer simplicity and cost-effectiveness for small to medium runs, while rotary filling systems provide higher speed and efficiency for large-scale operations. Your business benefits from evaluating throughput needs and product viscosity to select the most suitable option.

In-line filling vs rotary filling Infographic

libmatt.com

libmatt.com