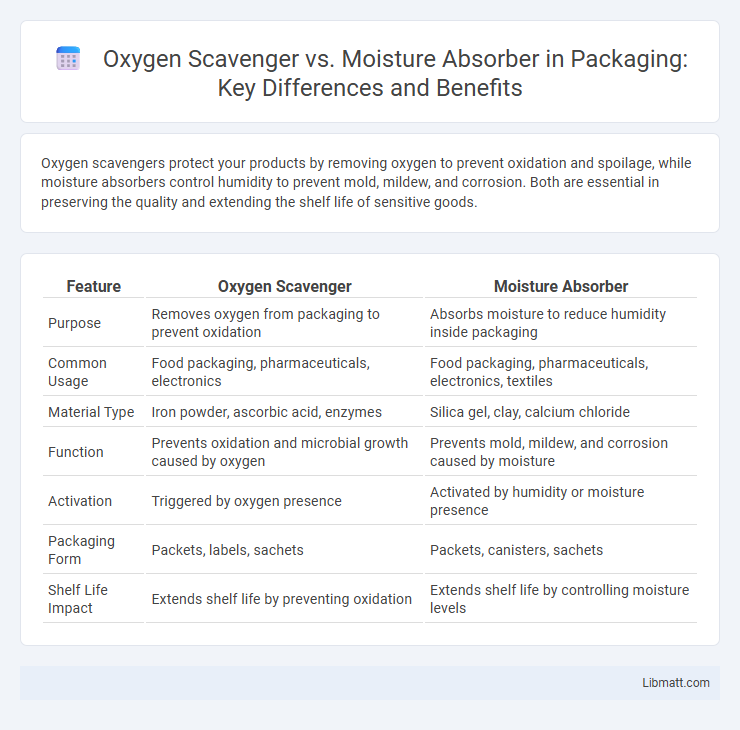

Oxygen scavengers protect your products by removing oxygen to prevent oxidation and spoilage, while moisture absorbers control humidity to prevent mold, mildew, and corrosion. Both are essential in preserving the quality and extending the shelf life of sensitive goods.

Table of Comparison

| Feature | Oxygen Scavenger | Moisture Absorber |

|---|---|---|

| Purpose | Removes oxygen from packaging to prevent oxidation | Absorbs moisture to reduce humidity inside packaging |

| Common Usage | Food packaging, pharmaceuticals, electronics | Food packaging, pharmaceuticals, electronics, textiles |

| Material Type | Iron powder, ascorbic acid, enzymes | Silica gel, clay, calcium chloride |

| Function | Prevents oxidation and microbial growth caused by oxygen | Prevents mold, mildew, and corrosion caused by moisture |

| Activation | Triggered by oxygen presence | Activated by humidity or moisture presence |

| Packaging Form | Packets, labels, sachets | Packets, canisters, sachets |

| Shelf Life Impact | Extends shelf life by preventing oxidation | Extends shelf life by controlling moisture levels |

Introduction to Oxygen Scavengers and Moisture Absorbers

Oxygen scavengers are chemical agents designed to remove or reduce oxygen levels within packaging to prevent oxidation and extend product shelf life. Moisture absorbers, such as silica gel and calcium chloride, are materials that control humidity by absorbing excess water vapor, thereby protecting products from mold, corrosion, and degradation. Both technologies play crucial roles in preserving food, pharmaceuticals, and electronics by maintaining optimal atmospheric conditions inside packaging environments.

How Oxygen Scavengers Work

Oxygen scavengers work by chemically reacting with oxygen molecules present in packaging environments to prevent oxidation and spoilage of products, especially in food and pharmaceuticals. These scavengers typically contain iron powder or other reactive compounds that absorb oxygen, thereby maintaining product freshness and extending shelf life. Unlike moisture absorbers that target humidity, oxygen scavengers specifically eliminate residual oxygen to inhibit microbial growth and preserve quality.

How Moisture Absorbers Work

Moisture absorbers function by attracting and trapping water vapor from the air, using materials such as silica gel, calcium chloride, or activated charcoal to reduce humidity levels in enclosed spaces. These substances chemically bind or physically absorb moisture, preventing mold growth, corrosion, and deterioration of stored goods. Unlike oxygen scavengers that target oxygen molecules, moisture absorbers specifically maintain low humidity to protect products sensitive to moisture damage.

Key Differences Between Oxygen Scavengers and Moisture Absorbers

Oxygen scavengers primarily target and remove oxygen molecules to prevent oxidation, spoilage, and microbial growth in packaged products, while moisture absorbers focus on reducing humidity levels by absorbing water vapor to prevent mold, corrosion, and degradation. Oxygen scavengers often contain iron powder or ascorbic acid, actively reacting with oxygen inside sealed environments, whereas moisture absorbers utilize desiccants such as silica gel, clay, or calcium chloride to absorb moisture passively. The choice between oxygen scavengers and moisture absorbers depends on the specific preservation needs, with oxygen scavengers ideal for oxidative protection and moisture absorbers crucial for controlling relative humidity.

Applications of Oxygen Scavengers

Oxygen scavengers are widely used in food packaging, pharmaceutical products, and industrial applications to extend shelf life by reducing oxygen levels that cause spoilage and oxidation. These scavengers help preserve the freshness of meat, dairy, and baked goods while protecting sensitive pharmaceuticals from oxidative degradation. In industrial settings, oxygen scavengers prevent rust and corrosion in metal components and electronic devices during storage and transportation.

Applications of Moisture Absorbers

Moisture absorbers are widely used in packaging industries to protect products like electronics, pharmaceuticals, and food from damage caused by excess humidity. In construction, moisture absorbers help prevent mold growth and structural deterioration by controlling indoor dampness. Your efforts to maintain product quality and longevity can greatly benefit from incorporating moisture absorbers in environments prone to high moisture levels.

Benefits of Using Oxygen Scavengers

Oxygen scavengers effectively extend the shelf life of food products by reducing oxidation and preventing spoilage, which maintains freshness and nutritional quality. These compounds help inhibit the growth of aerobic bacteria and mold, enhancing safety and reducing waste. Using oxygen scavengers in your packaging ensures greater product stability, making them invaluable for preserving sensitive items sensitive to oxygen exposure.

Benefits of Using Moisture Absorbers

Moisture absorbers effectively reduce humidity levels, preventing mold, mildew, and corrosion that can damage your belongings and packaging. They maintain the quality and shelf life of products by minimizing moisture-related deterioration. Using moisture absorbers creates a controlled environment that protects sensitive items from spoilage and enhances overall storage conditions.

Choosing the Right Solution: Factors to Consider

Selecting between oxygen scavengers and moisture absorbers depends primarily on the packaging environment and the sensitivity of the product to oxidation or humidity. Oxygen scavengers are ideal for products prone to spoilage or discoloration due to oxygen exposure, such as pharmaceuticals and food items with fat content, while moisture absorbers suit goods vulnerable to mold, corrosion, and texture changes caused by excess moisture, like electronics and dried foods. Key factors include the product's shelf life, packaging material permeability, and the specific atmospheric conditions inside the package to ensure maximum preservation efficiency.

Conclusion: Oxygen Scavenger vs Moisture Absorber

Oxygen scavengers effectively protect products by removing oxygen from packaging environments, preventing oxidation and spoilage, while moisture absorbers target humidity control to inhibit mold, corrosion, and moisture damage. Both play crucial roles in extending shelf life, but oxygen scavengers are essential for products sensitive to oxygen exposure such as food and pharmaceuticals, whereas moisture absorbers are critical in environments prone to excess moisture. Selecting the appropriate solution depends on the specific preservation needs, atmospheric conditions, and product sensitivity.

Oxygen scavenger vs moisture absorber Infographic

libmatt.com

libmatt.com