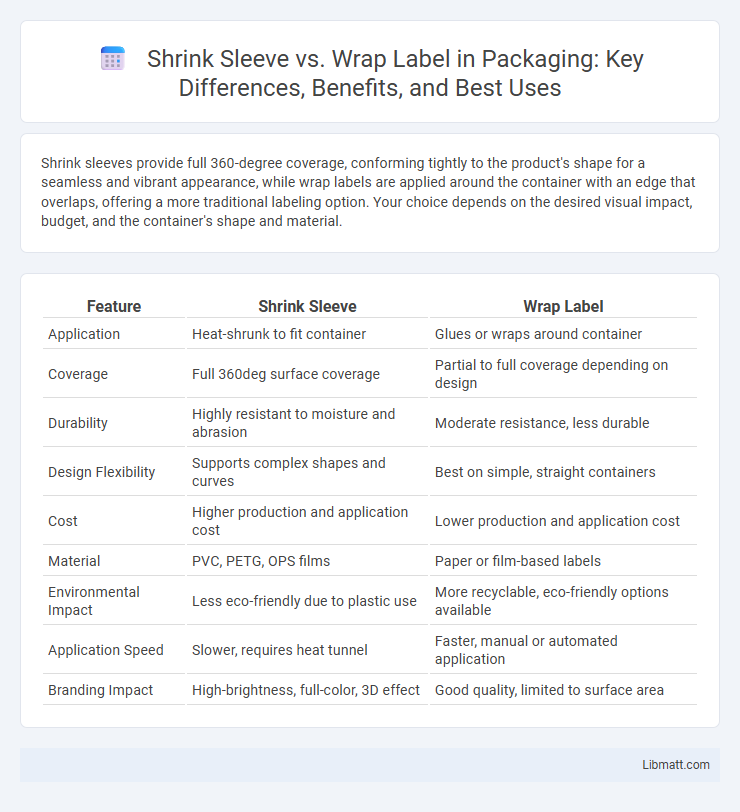

Shrink sleeves provide full 360-degree coverage, conforming tightly to the product's shape for a seamless and vibrant appearance, while wrap labels are applied around the container with an edge that overlaps, offering a more traditional labeling option. Your choice depends on the desired visual impact, budget, and the container's shape and material.

Table of Comparison

| Feature | Shrink Sleeve | Wrap Label |

|---|---|---|

| Application | Heat-shrunk to fit container | Glues or wraps around container |

| Coverage | Full 360deg surface coverage | Partial to full coverage depending on design |

| Durability | Highly resistant to moisture and abrasion | Moderate resistance, less durable |

| Design Flexibility | Supports complex shapes and curves | Best on simple, straight containers |

| Cost | Higher production and application cost | Lower production and application cost |

| Material | PVC, PETG, OPS films | Paper or film-based labels |

| Environmental Impact | Less eco-friendly due to plastic use | More recyclable, eco-friendly options available |

| Application Speed | Slower, requires heat tunnel | Faster, manual or automated application |

| Branding Impact | High-brightness, full-color, 3D effect | Good quality, limited to surface area |

Introduction to Shrink Sleeve and Wrap Label

Shrink sleeves are flexible plastic labels that conform tightly to the contours of a container through heat application, providing 360-degree branding and protection. Wrap labels are typically paper or plastic materials wrapped around a package, offering a simple and cost-effective labeling solution. Your choice between shrink sleeve and wrap label depends on factors like packaging shape, durability needs, and branding impact.

Definition and Materials Used

Shrink sleeves are plastic labels made from materials like PVC, PETG, or OPS that conform tightly to the shape of a container when heat is applied, offering 360-degree coverage and vibrant graphics. Wrap labels are typically made from flexible films or paper, designed to wrap around a container without shrinking, providing a traditional label appearance. Your choice depends on the desired visual impact and container shape, with shrink sleeves offering full-body decoration and wrap labels offering simpler, cost-effective solutions.

Application Processes Compared

Shrink sleeve labels require heat application that causes the film to conform tightly to the container's shape, ensuring 360-degree branding on complex surfaces. Wrap labels are applied by simply wrapping flexible printed materials around the container and securing with adhesive, suitable for straightforward cylindrical packaging. Your choice depends on the container's shape and desired visual impact, with shrink sleeves offering seamless coverage and wrap labels providing ease of application.

Design Flexibility and Branding Potential

Shrink sleeves offer superior design flexibility with 360-degree coverage, enabling vibrant, full-color graphics that enhance your product's branding potential. Wrap labels provide a more limited design area, typically covering only part of the container, which can restrict creativity and impactful visuals. Choosing shrink sleeves allows for seamless branding opportunities that capture consumers' attention from every angle.

Coverage and Visual Appeal

Shrink sleeves provide 360-degree coverage, allowing your design to wrap fully around the container, which enhances brand visibility and creates a seamless, high-impact visual appeal. Wrap labels typically cover only a portion of the product, offering limited design space and less eye-catching presentation. For maximum shelf differentiation and vibrant, distortion-free graphics, shrink sleeves are the superior choice for your packaging needs.

Durability and Resistance Factors

Shrink sleeves provide superior durability and resistance to moisture, heat, and abrasion, making them ideal for products exposed to harsh handling and environmental conditions. Wrap labels offer decent protection but are generally less resistant to tearing and wear, especially when subjected to water or friction. Choosing shrink sleeves enhances the longevity of your product's branding and maintains label integrity during transportation and storage.

Cost Analysis and Budget Considerations

Shrink sleeves generally involve higher upfront costs due to specialized printing and application equipment, but offer superior durability and full-body design that can justify the investment for premium branding. Wrap labels tend to be more cost-effective for smaller production runs, with lower material and application expenses, making them suitable for tight budget constraints. Evaluating total cost of ownership, including print runs, label durability, and packaging complexity, helps determine the best choice for budget-conscious manufacturers.

Sustainability and Environmental Impact

Shrink sleeves use less plastic compared to traditional wrap labels, reducing overall material consumption and waste. They are designed for full recyclability in many systems, supporting circular economy goals by facilitating easier separation during recycling processes. Wrap labels often involve adhesives that can complicate recycling, making shrink sleeves a more environmentally sustainable choice in packaging innovation.

Industry Suitability and Common Uses

Shrink sleeves excel in the beverage and personal care industries where 360-degree graphics and tamper-evident features are essential, providing full-body coverage on complex container shapes like bottles and cans. Wrap labels are commonly used in food and pharmaceutical sectors for simple application on cylindrical containers, offering cost-effective branding with clear, straight labeling. Both label types cater to specific packaging needs, with shrink sleeves favored for high-impact marketing and wrap labels preferred for straightforward product identification.

Choosing the Right Label for Your Product

Shrink sleeves provide 360-degree full-body coverage, offering vibrant, high-impact graphics that conform tightly to irregularly shaped containers, making them ideal for products needing maximum visual appeal. Wrap labels, typically made from paper or film, are easier and more cost-effective to apply, providing clear space for branding with moderate durability and water resistance. Your choice depends on product shape, budget, and desired shelf presence, ensuring the label enhances brand recognition while protecting the container.

Shrink sleeve vs wrap label Infographic

libmatt.com

libmatt.com