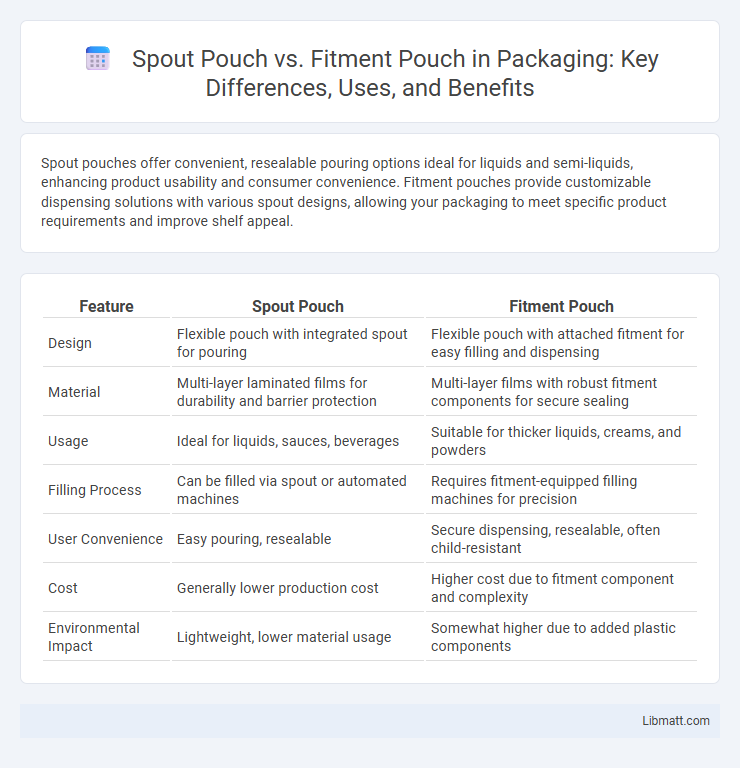

Spout pouches offer convenient, resealable pouring options ideal for liquids and semi-liquids, enhancing product usability and consumer convenience. Fitment pouches provide customizable dispensing solutions with various spout designs, allowing your packaging to meet specific product requirements and improve shelf appeal.

Table of Comparison

| Feature | Spout Pouch | Fitment Pouch |

|---|---|---|

| Design | Flexible pouch with integrated spout for pouring | Flexible pouch with attached fitment for easy filling and dispensing |

| Material | Multi-layer laminated films for durability and barrier protection | Multi-layer films with robust fitment components for secure sealing |

| Usage | Ideal for liquids, sauces, beverages | Suitable for thicker liquids, creams, and powders |

| Filling Process | Can be filled via spout or automated machines | Requires fitment-equipped filling machines for precision |

| User Convenience | Easy pouring, resealable | Secure dispensing, resealable, often child-resistant |

| Cost | Generally lower production cost | Higher cost due to fitment component and complexity |

| Environmental Impact | Lightweight, lower material usage | Somewhat higher due to added plastic components |

Introduction to Flexible Packaging Solutions

Spout pouches offer convenient resealable options ideal for liquids, enhancing portability and user experience, while fitment pouches integrate specialized closures for secure dispensing and leak prevention in flexible packaging solutions. Your choice between spout and fitment pouches depends on product viscosity, shelf life requirements, and convenience needs, maximizing brand appeal and functionality. Innovative materials and precision manufacturing techniques in flexible packaging ensure durability, sustainability, and customization for diverse industries.

What is a Spout Pouch?

A spout pouch is a flexible packaging solution featuring a resealable spout integrated into its structure, allowing for easy pouring and controlled dispensing of liquids or semi-liquids. Commonly used for beverages, sauces, and baby food, spout pouches provide convenience and reduce product wastage. Their lightweight and durable materials make them both cost-effective and environmentally friendly compared to rigid containers.

What is a Fitment Pouch?

A fitment pouch is a flexible packaging bag equipped with a resealable spout or valve, allowing easy pouring and dispensing of liquids, gels, or powders. Unlike standard spout pouches, fitment pouches provide enhanced convenience and improved product protection by preventing leaks and contamination. Your choice between a spout pouch and a fitment pouch depends on the specific dispensing needs and product preservation requirements.

Material Composition: Spout Pouch vs Fitment Pouch

Spout pouches typically use multi-layer laminated films combining PET, aluminum foil, and polyethylene for enhanced barrier properties and durability, ideal for liquid or semi-liquid packaging. Fitment pouches incorporate similar laminated films but are engineered to accommodate the attachment of screw caps or fitments, often requiring additional reinforcement around the neck area to ensure secure sealing. Both pouch types optimize material composition to balance flexibility, protection, and user convenience in liquid packaging applications.

Design and Structure Differences

Spout pouches feature a flexible body with a resealable spout, allowing easy pouring and refilling, while fitment pouches incorporate a rigid plastic or metal fitment for enhanced durability and controlled dispensing. The design of spout pouches emphasizes lightweight convenience and portability, whereas fitment pouches provide a more robust structure suitable for thicker liquids or products requiring precise flow control. Your choice between these two depends on the product's viscosity, usage frequency, and packaging stability requirements.

Filling and Dispensing Capabilities

Spout pouches offer superior filling efficiency thanks to their wide opening and flexible structure, enabling quick liquid or semi-liquid product packaging with minimal spillage. Fitment pouches feature integrated dispensing caps that provide controlled flow, ideal for precise portioning and resealing, enhancing product freshness and user convenience. The combination of filling speed in spout pouches versus the controlled dispensing of fitment pouches determines the best choice depending on the product viscosity and end-user needs.

Applications and Industry Uses

Spout pouches are widely used in the food and beverage industry for packaging liquid or semi-liquid products like juices, sauces, and baby food, offering convenience and resealability. Fitment pouches, equipped with specialized dispensing valves, are preferred in sectors such as chemicals, personal care, and detergents, ensuring controlled flow and product protection. Your choice depends on the specific application requirements, including product viscosity, dispensing needs, and industry standards.

Cost Comparison and Efficiency

Spout pouches typically incur higher production costs due to their complex manufacturing process and additional materials required for the spout. Fitment pouches generally offer more cost-efficient packaging solutions, benefiting from simpler fabrication and easier automation in filling lines. Efficiency-wise, spout pouches provide superior convenience and resealability, while fitment pouches excel in production speed and lower overall packaging expenses.

Sustainability and Environmental Impact

Spout pouches typically use multiple materials that can challenge recycling efforts, increasing environmental waste, while fitment pouches often integrate easily recyclable components, promoting better sustainability. The reduced material usage and enhanced resealability of fitment pouches contribute to lower carbon footprints and less plastic pollution. Brands focusing on eco-friendly packaging increasingly adopt fitment pouches to meet consumer demand for sustainable solutions.

Choosing Between Spout and Fitment Pouches

Choosing between spout pouches and fitment pouches depends on your product's dispensing needs and packaging functionality. Spout pouches offer easy pouring and resealability, ideal for liquids and semi-liquids, while fitment pouches provide a secure and leak-proof fit, perfect for thicker products or those requiring controlled flow. Your decision should balance convenience, product type, and consumer usability to enhance overall packaging efficiency.

Spout pouch vs fitment pouch Infographic

libmatt.com

libmatt.com