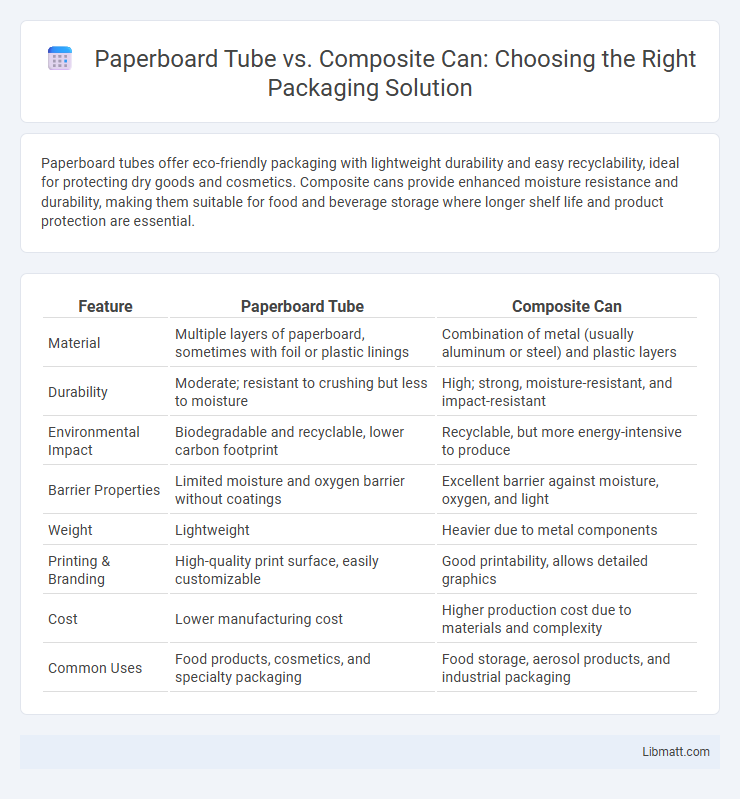

Paperboard tubes offer eco-friendly packaging with lightweight durability and easy recyclability, ideal for protecting dry goods and cosmetics. Composite cans provide enhanced moisture resistance and durability, making them suitable for food and beverage storage where longer shelf life and product protection are essential.

Table of Comparison

| Feature | Paperboard Tube | Composite Can |

|---|---|---|

| Material | Multiple layers of paperboard, sometimes with foil or plastic linings | Combination of metal (usually aluminum or steel) and plastic layers |

| Durability | Moderate; resistant to crushing but less to moisture | High; strong, moisture-resistant, and impact-resistant |

| Environmental Impact | Biodegradable and recyclable, lower carbon footprint | Recyclable, but more energy-intensive to produce |

| Barrier Properties | Limited moisture and oxygen barrier without coatings | Excellent barrier against moisture, oxygen, and light |

| Weight | Lightweight | Heavier due to metal components |

| Printing & Branding | High-quality print surface, easily customizable | Good printability, allows detailed graphics |

| Cost | Lower manufacturing cost | Higher production cost due to materials and complexity |

| Common Uses | Food products, cosmetics, and specialty packaging | Food storage, aerosol products, and industrial packaging |

Introduction to Paperboard Tubes and Composite Cans

Paperboard tubes are cylindrical containers made from layers of paperboard, offering lightweight, eco-friendly packaging with excellent printability and structural strength. Composite cans combine materials like paperboard, aluminum, and plastic to create durable containers with enhanced barrier properties suitable for food and industrial products. Both packaging types provide customizable designs but differ significantly in material composition and environmental impact.

Material Composition and Structure

Paperboard tubes consist primarily of layers of cellulose fibers tightly wound and glued to form a sturdy, lightweight cylinder ideal for packaging lightweight goods and cosmetics. Composite cans feature a more complex structure incorporating multiple materials such as metal ends, a composite fiber body, and often a plastic lining to enhance durability, moisture resistance, and product preservation. The layered construction of composite cans provides superior strength and barrier properties compared to the predominantly fiber-based paperboard tubes.

Manufacturing Processes Compared

Paperboard tubes are produced by spirally winding layers of paperboard around a mandrel, followed by adhesive bonding and drying, enabling lightweight and cost-effective packaging. Composite cans combine metal and polymer layers through extrusion and lamination, which provides enhanced barrier properties and durability but involves a more complex, energy-intensive manufacturing process. Your choice between these depends on the desired strength, barrier performance, and production scalability for your packaging needs.

Sustainability and Environmental Impact

Paperboard tubes offer a more sustainable packaging solution due to their renewable materials and ease of recycling, reducing landfill waste and carbon footprint. Composite cans, often made from multiple materials including plastic and metal, present challenges in recycling and typically require more energy-intensive processing. Choosing paperboard tubes supports circular economy principles by promoting biodegradability and minimizing environmental impact throughout the product lifecycle.

Strength and Durability Analysis

Paperboard tubes offer lightweight strength with moderate durability, ideal for packaging dry goods due to their resistance to crushing under standard loads. Composite cans combine metal and plastic layers, providing superior impact resistance and moisture protection, making them more durable for long-term storage and rough handling. The structural integrity of composite cans surpasses that of paperboard tubes, especially in high-stress environments requiring enhanced barrier properties.

Cost Efficiency and Economics

Paperboard tubes offer cost efficiency due to lower raw material expenses and simpler manufacturing processes compared to composite cans, which often require multiple materials and intricate assembly. Composite cans provide enhanced durability and barrier protection, potentially reducing product losses and costs related to spoilage, but their higher production costs can impact overall economics. Your choice depends on balancing initial material costs against long-term savings from product preservation and brand positioning.

Packaging Versatility and Applications

Paperboard tubes offer exceptional packaging versatility, accommodating a wide range of products from cosmetics and food items to industrial components due to their lightweight, customizable design and eco-friendly appeal. Composite cans provide robust protection for perishable goods like powdered food, snacks, and chemicals, combining metal and paper layers for durability and moisture resistance. Both packaging options deliver distinct advantages tailored to specific applications, with paperboard tubes excelling in sustainability and visual appeal, while composite cans prioritize barrier properties and product preservation.

Customization and Branding Options

Paperboard tubes offer extensive customization with printed designs, embossing, and unique shapes, making them ideal for premium branding and product differentiation. Composite cans provide limited surface area for high-resolution labeling but support durable graphics and secure sealing options. Both packaging types enable vibrant branding, but paperboard tubes excel in tactile finishes and bespoke aesthetics.

Consumer Perception and Usability

Paperboard tubes offer a natural, eco-friendly appeal that often attracts environmentally conscious consumers seeking sustainable packaging options. Composite cans provide superior durability and product protection, enhancing usability for items requiring longer shelf life or moisture resistance. Your choice between these packaging types can influence brand perception and consumer satisfaction based on preferences for sustainability versus functionality.

Choosing the Right Option for Your Product

Paperboard tubes offer lightweight, cost-effective packaging ideal for dry goods and cosmetics, enhancing sustainability with easy recyclability. Composite cans provide superior durability and moisture resistance, making them suitable for food products and high-moisture contents. Selecting the right option depends on your product's requirements for protection, shelf life, and environmental impact.

Paperboard tube vs composite can Infographic

libmatt.com

libmatt.com