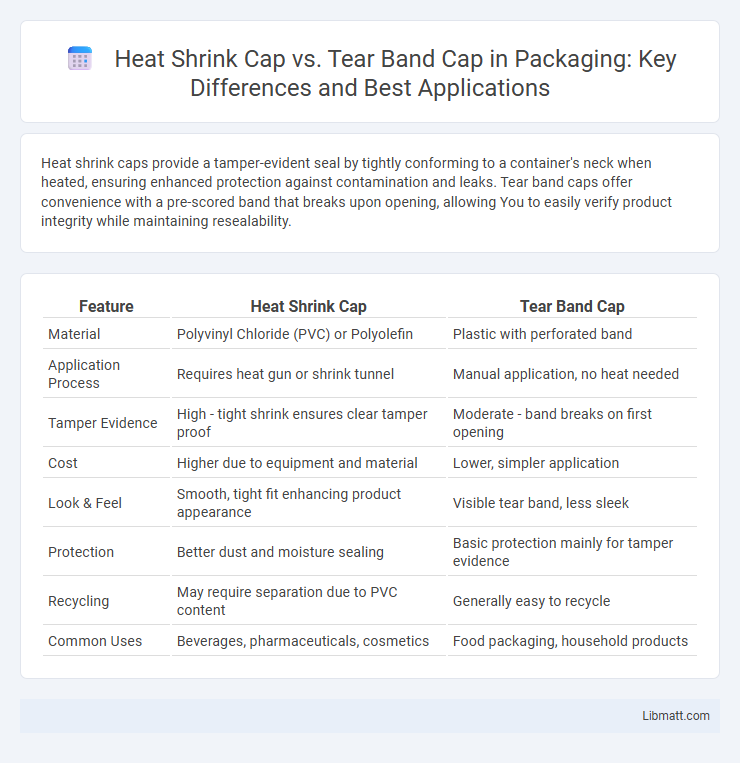

Heat shrink caps provide a tamper-evident seal by tightly conforming to a container's neck when heated, ensuring enhanced protection against contamination and leaks. Tear band caps offer convenience with a pre-scored band that breaks upon opening, allowing You to easily verify product integrity while maintaining resealability.

Table of Comparison

| Feature | Heat Shrink Cap | Tear Band Cap |

|---|---|---|

| Material | Polyvinyl Chloride (PVC) or Polyolefin | Plastic with perforated band |

| Application Process | Requires heat gun or shrink tunnel | Manual application, no heat needed |

| Tamper Evidence | High - tight shrink ensures clear tamper proof | Moderate - band breaks on first opening |

| Cost | Higher due to equipment and material | Lower, simpler application |

| Look & Feel | Smooth, tight fit enhancing product appearance | Visible tear band, less sleek |

| Protection | Better dust and moisture sealing | Basic protection mainly for tamper evidence |

| Recycling | May require separation due to PVC content | Generally easy to recycle |

| Common Uses | Beverages, pharmaceuticals, cosmetics | Food packaging, household products |

Introduction to Heat Shrink Caps and Tear Band Caps

Heat shrink caps create a tamper-evident seal by shrinking tightly around containers when exposed to heat, providing secure packaging and protection from contamination. Tear band caps feature a perforated strip that must be broken to open the container, offering easy visibility of tampering while maintaining freshness. Both cap types enhance product safety but differ in application methods and consumer convenience.

Key Differences Between Heat Shrink and Tear Band Caps

Heat shrink caps provide a uniform, tamper-evident seal by shrinking tightly over bottle tops when heated, enhancing security and freshness. Tear band caps feature a perforated ring that breaks upon opening, offering a clear indication of tampering without requiring heat application. Your choice depends on factors like production efficiency, tamper evidence preference, and sealing strength needed for your product.

Material Composition and Durability

Heat shrink caps are typically made from polyvinyl chloride (PVC) or polyethylene, offering excellent flexibility and strong resistance to tampering and environmental factors, ensuring long-lasting durability. Tear band caps are often composed of polypropylene (PP) or high-density polyethylene (HDPE), designed with a breakaway band that provides an evident tamper-evident feature but may have slightly less flexibility than heat shrink caps. Your choice between the two should consider the specific needs for material strength and tamper evidence in packaging.

Application Processes: Heat Shrink vs. Tear Band

Heat shrink caps are applied using heat sources such as heat guns or tunnels, causing the material to contract tightly around the container for a secure seal, making them ideal for tamper-evident packaging in pharmaceuticals and beverages. Tear band caps feature a perforated ring that breaks upon opening, providing clear evidence of tampering and are typically applied by standard capping machines without the need for heat. The choice between heat shrink and tear band caps depends on packaging speed, equipment availability, and the level of tamper-evidence required in industries like food, cosmetics, and chemicals.

Tamper Evidence and Security Features

Heat shrink caps provide a secure tamper-evident seal by tightly conforming to the bottle neck, creating a visible indication if the product has been opened. Tear band caps incorporate a perforated strip that breaks away upon opening, offering clear evidence of tampering with minimal effort. Your choice between these caps should depend on the level of tamper evidence and security feature visibility required for your product's packaging integrity.

Usability and Consumer Convenience

Heat shrink caps provide a secure, tamper-evident seal that is easy to apply and difficult to remove without visible damage, enhancing product safety and freshness. Tear band caps offer a convenient grip feature, allowing consumers to open bottles effortlessly without twisting off the entire cap, improving ease of use especially for children and elderly users. Your choice depends on whether tamper evidence or quick access is the priority in packaging design.

Cost Analysis and Production Efficiency

Heat shrink caps typically incur higher initial material and machinery costs compared to tear band caps but can lead to reduced labor expenses due to faster application and fewer defects. Tear band caps, while often less expensive in raw materials, may require more manual handling and longer production times, impacting overall manufacturing efficiency. Evaluating total cost of ownership and production throughput is essential for selecting the optimal cap type in packaging operations.

Environmental Impact and Sustainability

Heat shrink caps often use PVC or PET materials, which can pose environmental challenges due to slower biodegradability and potential microplastic pollution. Tear band caps, commonly made from polypropylene or polyethylene, tend to have better recyclability and lower environmental footprint as they require less energy in the manufacturing process and reduce plastic waste through easy separation. Choosing tear band caps can contribute to improved sustainability efforts by minimizing landfill impact and facilitating more efficient recycling streams in packaging industries.

Industry Suitability and Popular Applications

Heat shrink caps are widely used in the food and beverage industry for sealing bottles and providing tamper-evident protection, especially in juice and spirit packaging. Tear band caps are favored in pharmaceutical and cosmetic sectors due to their easy peel-off feature, ensuring consumer convenience and product integrity. Both cap types enhance safety and freshness but cater to distinct industry needs based on application requirements and regulatory standards.

Choosing the Right Cap for Your Product

Heat shrink caps provide a tamper-evident seal and a snug fit, ideal for securing bottles with irregular neck shapes and ensuring product integrity. Tear band caps offer a crisp, audible break when opened, enhancing consumer confidence with visible tamper evidence and ease of use. Choosing the right cap for your product depends on package design, user experience priorities, and the level of security required for your brand.

Heat shrink cap vs tear band cap Infographic

libmatt.com

libmatt.com