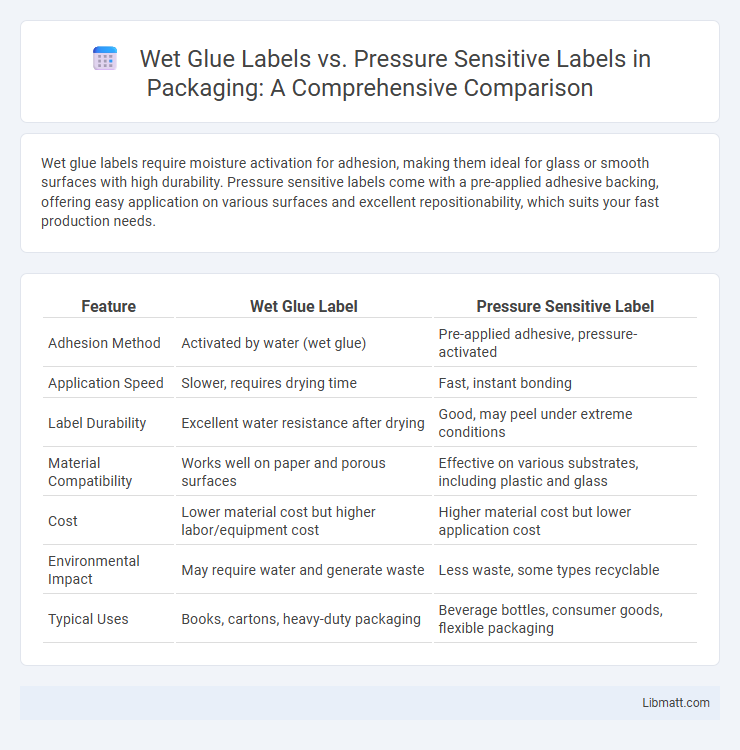

Wet glue labels require moisture activation for adhesion, making them ideal for glass or smooth surfaces with high durability. Pressure sensitive labels come with a pre-applied adhesive backing, offering easy application on various surfaces and excellent repositionability, which suits your fast production needs.

Table of Comparison

| Feature | Wet Glue Label | Pressure Sensitive Label |

|---|---|---|

| Adhesion Method | Activated by water (wet glue) | Pre-applied adhesive, pressure-activated |

| Application Speed | Slower, requires drying time | Fast, instant bonding |

| Label Durability | Excellent water resistance after drying | Good, may peel under extreme conditions |

| Material Compatibility | Works well on paper and porous surfaces | Effective on various substrates, including plastic and glass |

| Cost | Lower material cost but higher labor/equipment cost | Higher material cost but lower application cost |

| Environmental Impact | May require water and generate waste | Less waste, some types recyclable |

| Typical Uses | Books, cartons, heavy-duty packaging | Beverage bottles, consumer goods, flexible packaging |

Introduction to Wet Glue Labels and Pressure Sensitive Labels

Wet glue labels require the application of an adhesive during the labeling process, making them suitable for sturdy bonding on glass, metal, and plastic containers. Pressure sensitive labels feature a pre-applied adhesive backing, allowing for quick and easy application without water or heat, ideal for flexible packaging and containers with varying shapes. Both labeling types offer distinct advantages in durability, application speed, and compatibility with different surfaces in industries such as food, beverage, and pharmaceuticals.

Key Differences Between Wet Glue and Pressure Sensitive Labels

Wet glue labels require application of adhesive before attaching to the surface, providing strong, permanent bonding suited for glass and metal containers. Pressure sensitive labels feature a pre-applied adhesive that sticks instantly to various materials like plastic, paper, or cardboard without additional glue, enabling faster and more versatile labeling processes. Key differences include adhesive application method, bond strength, surface compatibility, and ease of use, with wet glue labels excelling in durability and pressure sensitive labels offering convenience and flexibility.

Application Methods: Traditional vs. Modern Labeling

Wet glue labels require a separate adhesive application step involving water-activated glue, making them ideal for traditional packaging processes where precise placement is less critical. Pressure-sensitive labels feature a pre-applied adhesive backing, allowing for quick and efficient application using modern automated labeling machines that enhance production speed and accuracy. Your choice between these labeling methods depends on the balance between cost, application speed, and the specific requirements of your packaging line.

Material Compatibility: What Surfaces Work Best

Wet glue labels are ideal for porous materials such as paper, cardboard, and certain fabrics, offering strong adhesion when applied to rough or absorbent surfaces. Pressure sensitive labels work best on smooth, non-porous surfaces like glass, plastics, and metals, providing instant stickiness without requiring moisture. Choosing the right label depends on your surface type to ensure optimal bonding and durability.

Cost Comparison: Wet Glue vs Pressure Sensitive Labels

Wet glue labels generally have a lower initial cost due to simpler adhesive materials but incur higher labor and application expenses, making them less economical for large production runs. Pressure sensitive labels, while often more expensive upfront, reduce application time and waste, resulting in lower overall costs for high-volume or automated labeling processes. Your choice between wet glue and pressure sensitive labels should balance upfront material costs against long-term efficiency and scalability.

Production Speed and Efficiency: Which is Faster?

Pressure sensitive labels offer faster production speed and higher efficiency compared to wet glue labels, as they can be applied instantly without drying time. Wet glue labels require adhesive application and time to set, slowing down the labeling process in high-volume production environments. This makes pressure sensitive labeling the preferred choice for operations prioritizing rapid throughput and minimal downtime.

Durability and Adhesion: Performance in Real-World Conditions

Wet glue labels provide strong, water-resistant adhesion best suited for glass and smooth surfaces but may weaken on rough or oily substrates, affecting long-term durability. Pressure sensitive labels offer versatile adhesion across diverse materials, maintaining consistent performance under varying temperatures and humidity, making them ideal for dynamic environments. Your choice depends on the application, with pressure sensitive labels generally excelling in real-world conditions requiring flexibility and durability.

Sustainability and Environmental Impact

Wet glue labels often use water-based adhesives that can be more environmentally friendly but require additional resources for drying and application, impacting energy consumption. Pressure sensitive labels, typically made with acrylic adhesives, offer recyclability advantages by allowing easier label removal during recycling but may involve synthetic materials that challenge compostability. Evaluating your packaging's sustainability involves choosing the label type that best aligns with your environmental goals and waste management capabilities.

Industry Preferences and Use Cases

Wet glue labels are predominantly preferred in industries requiring high durability and strong adhesion, such as beverage bottling, where labels must withstand moisture and temperature changes. Pressure sensitive labels dominate sectors like cosmetics and pharmaceuticals due to their ease of application, versatility, and suitability for uneven or curved surfaces. Both label types are essential, with wet glue labels favored for long-term adherence and pressure sensitive labels chosen for quick, efficient labeling processes.

Choosing the Right Labeling Solution for Your Product

Wet glue labels provide a traditional adhesive option that works well on a variety of packaging materials, offering strong bonds especially on glass and paper surfaces. Pressure sensitive labels feature self-adhesive backing, simplifying application and enabling quick, clean placement ideal for high-speed production lines and diverse container shapes. Choosing the right labeling solution for your product depends on factors like substrate compatibility, application speed, and environmental resistance, ensuring your packaging maintains durability and visual appeal.

Wet glue label vs pressure sensitive label Infographic

libmatt.com

libmatt.com