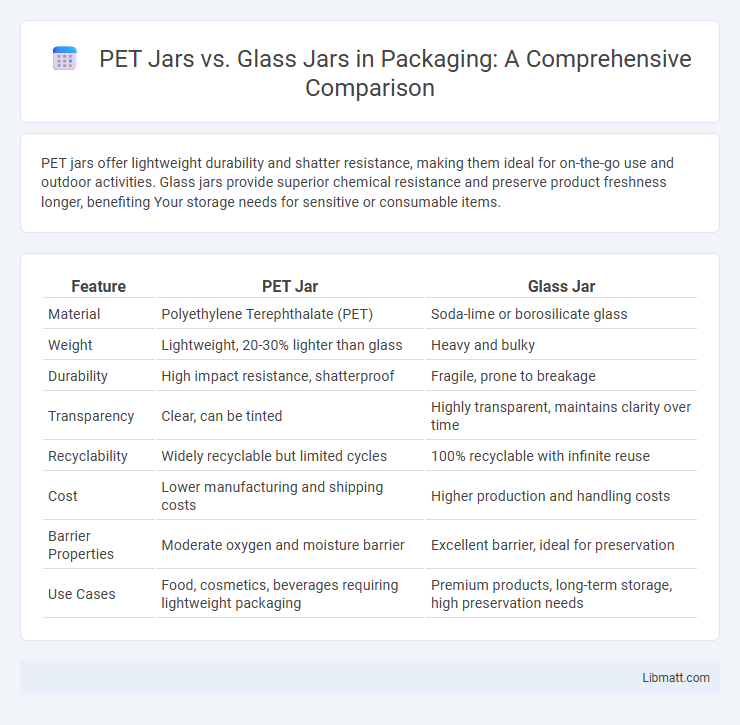

PET jars offer lightweight durability and shatter resistance, making them ideal for on-the-go use and outdoor activities. Glass jars provide superior chemical resistance and preserve product freshness longer, benefiting Your storage needs for sensitive or consumable items.

Table of Comparison

| Feature | PET Jar | Glass Jar |

|---|---|---|

| Material | Polyethylene Terephthalate (PET) | Soda-lime or borosilicate glass |

| Weight | Lightweight, 20-30% lighter than glass | Heavy and bulky |

| Durability | High impact resistance, shatterproof | Fragile, prone to breakage |

| Transparency | Clear, can be tinted | Highly transparent, maintains clarity over time |

| Recyclability | Widely recyclable but limited cycles | 100% recyclable with infinite reuse |

| Cost | Lower manufacturing and shipping costs | Higher production and handling costs |

| Barrier Properties | Moderate oxygen and moisture barrier | Excellent barrier, ideal for preservation |

| Use Cases | Food, cosmetics, beverages requiring lightweight packaging | Premium products, long-term storage, high preservation needs |

Introduction to PET Jars and Glass Jars

PET jars, made from polyethylene terephthalate, provide lightweight, shatter-resistant packaging ideal for food and cosmetic products, enhancing portability and reducing transportation costs. Glass jars offer superior chemical resistance and airtight sealing, preserving product freshness with a premium, eco-friendly appeal favored in luxury and artisanal markets. Both materials support sustainable recycling efforts, with PET jars excelling in impact resistance and recyclability, while glass jars enable infinite reuse without quality degradation.

Material Composition and Manufacturing Process

PET jars are made from polyethylene terephthalate, a lightweight, durable plastic polymer produced through a polymerization process involving terephthalic acid and ethylene glycol. Glass jars consist of silica sand, soda ash, and limestone melted at high temperatures followed by molding and annealing to improve strength and reduce stress. The manufacturing of PET jars allows for faster production cycles and lower energy consumption compared to the energy-intensive glass melting and forming process.

Weight and Portability Comparison

PET jars are significantly lighter than glass jars, making them easier to carry and ideal for on-the-go use. Their lightweight nature reduces shipping costs and enhances portability without compromising durability. If you prioritize convenience and ease of transport, PET jars offer a superior alternative to heavier glass options.

Durability and Breakage Resistance

PET jars offer superior durability and exceptional breakage resistance compared to glass jars, making them ideal for environments where impact is frequent. Their lightweight, shatterproof construction reduces the risk of damage during transportation and handling, ensuring product safety. Your choice of PET jars enhances reliability and longevity in packaging without compromising on strength.

Environmental Impact and Sustainability

PET jars offer lightweight properties and recyclability, reducing transportation emissions and resource consumption compared to glass jars. Glass jars, made from natural materials, are reusable and infinitely recyclable without degrading quality, supporting a circular economy. Your choice impacts landfill waste and carbon footprint, with glass jars generally favored for long-term environmental sustainability despite higher initial energy use in production.

Cost Analysis: PET Jar vs Glass Jar

PET jars generally offer lower production and transportation costs compared to glass jars due to their lightweight and shatter-resistant properties. Glass jars tend to have higher manufacturing expenses and increased shipping costs because of their weight and fragility, impacting your overall budget. Choosing PET jars can lead to significant savings in logistics and handling without compromising container quality.

Safety and Chemical Leaching Concerns

PET jars are generally safer for packaging due to their shatter-resistant properties and lower risk of breakage compared to glass jars. However, PET containers may pose chemical leaching concerns, especially when exposed to high temperatures or prolonged storage, potentially releasing antimony and other additives into the contents. Glass jars do not leach chemicals and are non-reactive, making them a preferred option for preserving the purity and safety of sensitive food and beverage products.

Food Preservation and Shelf Life

PET jars provide excellent barrier properties against moisture and oxygen, significantly extending food shelf life compared to traditional glass jars. Their lightweight and impact-resistant design reduces breakage risk during transportation, maintaining product integrity and freshness. Glass jars, while offering superior chemical inertness, may allow subtle gas exchange over time, potentially affecting food preservation in long-term storage.

Design Flexibility and Aesthetic Appeal

PET jars offer superior design flexibility with lightweight, shatterproof construction and customizable shapes and colors, making them ideal for vibrant branding. Glass jars provide classic aesthetic appeal with a premium, transparent look that enhances product visibility and conveys quality. Your choice depends on whether you prioritize modern customization or timeless elegance for your packaging needs.

Which Jar is Best for Your Needs?

PET jars offer lightweight durability and shatter resistance, making them ideal for on-the-go and outdoor use, while glass jars provide superior chemical stability and an airtight seal, preserving freshness and flavor for long-term storage. Choose PET jars for cost-effective, break-resistant packaging in industries like cosmetics and food delivery; glass jars suit products requiring premium presentation and enhanced shelf life. Assess factors such as product sensitivity, portability, environmental impact, and aesthetic preferences to determine the best jar for your specific needs.

PET jar vs glass jar Infographic

libmatt.com

libmatt.com