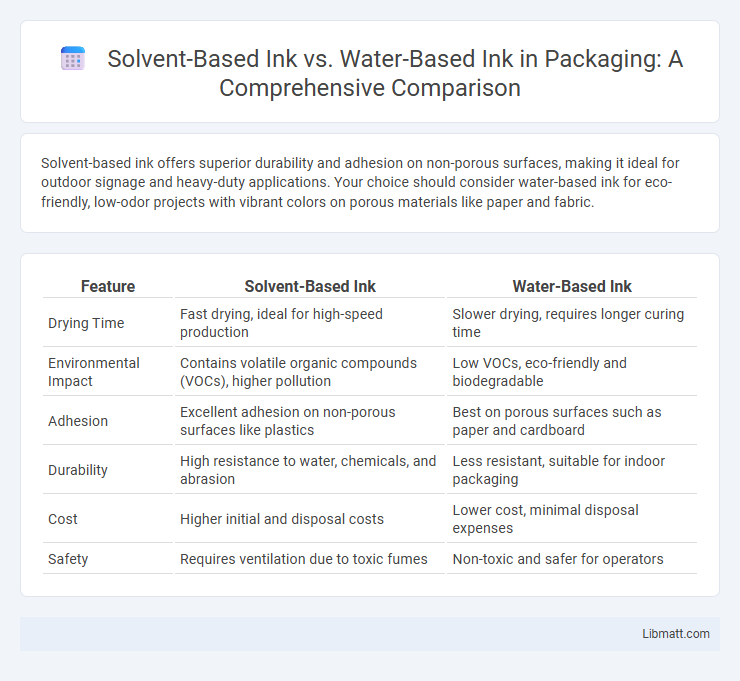

Solvent-based ink offers superior durability and adhesion on non-porous surfaces, making it ideal for outdoor signage and heavy-duty applications. Your choice should consider water-based ink for eco-friendly, low-odor projects with vibrant colors on porous materials like paper and fabric.

Table of Comparison

| Feature | Solvent-Based Ink | Water-Based Ink |

|---|---|---|

| Drying Time | Fast drying, ideal for high-speed production | Slower drying, requires longer curing time |

| Environmental Impact | Contains volatile organic compounds (VOCs), higher pollution | Low VOCs, eco-friendly and biodegradable |

| Adhesion | Excellent adhesion on non-porous surfaces like plastics | Best on porous surfaces such as paper and cardboard |

| Durability | High resistance to water, chemicals, and abrasion | Less resistant, suitable for indoor packaging |

| Cost | Higher initial and disposal costs | Lower cost, minimal disposal expenses |

| Safety | Requires ventilation due to toxic fumes | Non-toxic and safer for operators |

Introduction to Printing Inks

Solvent-based inks consist of pigments suspended in organic solvents, offering excellent adhesion and durability on non-porous surfaces like plastics and metals. Water-based inks use water as the primary solvent, providing eco-friendly, low-odor options ideal for porous materials such as paper and textiles. Printing ink selection depends on substrate compatibility, environmental regulations, and desired print quality for specific applications.

What Are Solvent-Based Inks?

Solvent-based inks use organic solvents to dissolve pigments, providing strong adhesion, water resistance, and fast drying times ideal for outdoor signage and durable prints. They deliver vibrant colors with excellent durability on non-porous substrates like vinyl and plastics, making them suitable for long-term applications. Your choice of solvent-based ink ensures robust performance where moisture and weather resistance are critical.

What Are Water-Based Inks?

Water-based inks are composed primarily of water as the solvent, making them environmentally friendly and less toxic compared to solvent-based inks. These inks offer excellent color vibrancy and adhesion on porous materials, ideal for applications like textiles and paper printing. Their quick drying time and low VOC emissions align with sustainable printing practices, promoting safer indoor air quality.

Key Differences Between Solvent and Water-Based Inks

Solvent-based inks use organic solvents that evaporate quickly, providing excellent adhesion and durability on non-porous surfaces like vinyl and plastics, making them ideal for outdoor signage. Water-based inks primarily use water as a solvent, offering eco-friendly benefits, lower VOC emissions, and vibrant color reproduction on porous materials such as paper and fabric. The choice between solvent and water-based inks depends on substrate compatibility, environmental regulations, and desired print longevity.

Print Quality Comparison

Solvent-based ink delivers superior print quality on non-porous surfaces, offering vibrant colors, high durability, and resistance to fading and scratches, making it ideal for outdoor signage and vehicle wraps. Water-based ink provides excellent print quality on porous materials such as paper and textiles, producing soft, eco-friendly prints with smooth gradients and greater detail. Choosing between the two depends on the substrate and the desired balance of environmental impact versus print longevity and vibrancy.

Environmental Impact and Safety

Solvent-based inks release volatile organic compounds (VOCs) that contribute to air pollution and pose health risks during printing and drying processes, requiring specialized ventilation and protective equipment. Water-based inks have a lower environmental impact with minimal VOC emissions, making them safer for workers and reducing indoor air pollution. Your choice of water-based ink supports eco-friendly practices and enhances workplace safety by minimizing exposure to harmful chemicals.

Application and Material Compatibility

Solvent-based inks excel in printing on non-porous materials such as vinyl, plastics, and metals, making them ideal for outdoor signage and durable labels due to their strong adhesion and weather resistance. Water-based inks are better suited for porous substrates like paper, textiles, and biodegradable materials, offering eco-friendly properties and softer finishes ideal for packaging and fabric printing. Compatibility with the substrate type directly influences drying time, durability, and environmental impact, with solvent inks providing robust performance on synthetic materials and water-based inks favored for sustainable applications on natural fibers.

Cost Efficiency and Operational Considerations

Solvent-based inks generally offer higher durability and faster drying times, making them cost-efficient for high-volume industrial printing, while their VOC emissions require specialized ventilation and handling, increasing operational costs. Water-based inks are more environmentally friendly with lower initial equipment expenses and reduced regulatory compliance costs but may demand longer drying times and additional maintenance to prevent clogging, impacting production speed. Your choice depends on balancing upfront investment and ongoing operational efficiency against environmental and safety requirements.

Industry Trends and Emerging Technologies

Solvent-based ink continues to dominate in industrial applications due to its durability and adhesion on non-porous surfaces, driving demand in automotive and packaging sectors. Water-based ink gains momentum with eco-friendly regulations and consumer preference for sustainable products, supported by advancements in pigment dispersion and drying technologies. Your choice between these inks can leverage emerging innovations like UV curing and bio-based solvents, aligning with industry trends toward performance and environmental responsibility.

Choosing the Right Ink for Your Needs

Solvent-based ink offers superior durability and vibrant colors, making it ideal for outdoor signage and applications requiring weather resistance. Water-based ink provides eco-friendly, non-toxic properties and is better suited for indoor printing and materials sensitive to chemicals. Understanding your project's environment and longevity requirements ensures you select the right ink to meet your specific printing needs.

Solvent-based ink vs water-based ink Infographic

libmatt.com

libmatt.com