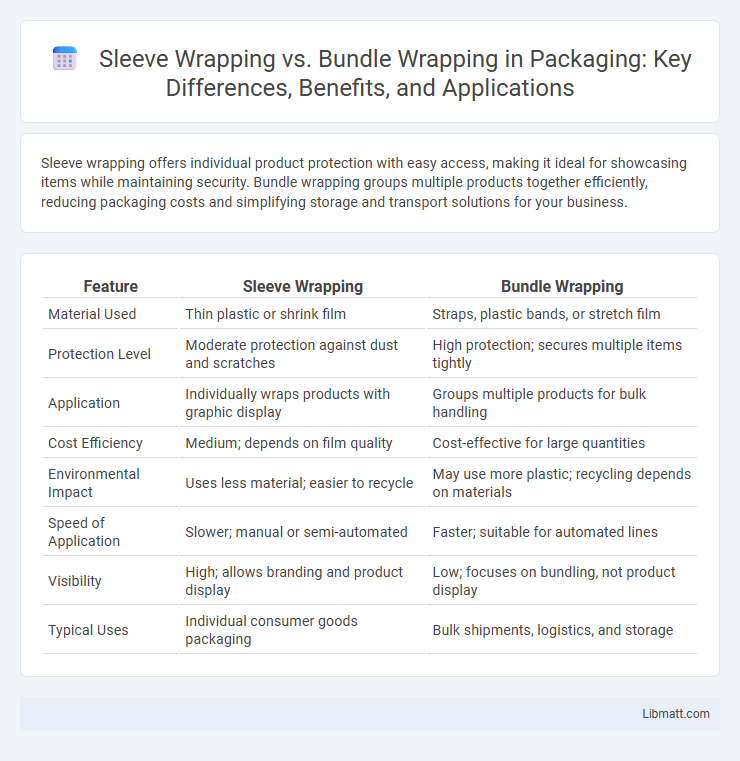

Sleeve wrapping offers individual product protection with easy access, making it ideal for showcasing items while maintaining security. Bundle wrapping groups multiple products together efficiently, reducing packaging costs and simplifying storage and transport solutions for your business.

Table of Comparison

| Feature | Sleeve Wrapping | Bundle Wrapping |

|---|---|---|

| Material Used | Thin plastic or shrink film | Straps, plastic bands, or stretch film |

| Protection Level | Moderate protection against dust and scratches | High protection; secures multiple items tightly |

| Application | Individually wraps products with graphic display | Groups multiple products for bulk handling |

| Cost Efficiency | Medium; depends on film quality | Cost-effective for large quantities |

| Environmental Impact | Uses less material; easier to recycle | May use more plastic; recycling depends on materials |

| Speed of Application | Slower; manual or semi-automated | Faster; suitable for automated lines |

| Visibility | High; allows branding and product display | Low; focuses on bundling, not product display |

| Typical Uses | Individual consumer goods packaging | Bulk shipments, logistics, and storage |

Introduction to Sleeve Wrapping and Bundle Wrapping

Sleeve wrapping uses a precoiled plastic film that is slipped over individual products for protective coverage, ensuring easy application and clear product visibility. Bundle wrapping involves securing multiple items together with stretch film or shrink wrap, enhancing stability during transport and storage. Both methods optimize packaging efficiency and product protection in retail and logistics environments.

What Is Sleeve Wrapping?

Sleeve wrapping involves enclosing individual products in a flexible, transparent film that snugly fits around each item, protecting it from dust and damage while maintaining visibility. This method enhances product presentation and facilitates easy handling during transportation and retail display. Your choice of sleeve wrapping supports efficient packaging and durability for single items compared to the bulk-oriented approach of bundle wrapping.

What Is Bundle Wrapping?

Bundle wrapping involves grouping multiple products together and securing them with a single layer of plastic film or shrink wrap, enhancing efficiency in packaging and transportation. This method improves load stability and reduces handling costs by consolidating items into one manageable unit. You can optimize warehouse storage and streamline shipping processes through effective bundle wrapping techniques.

Core Differences Between Sleeve and Bundle Wrapping

Sleeve wrapping involves encasing products in a single, continuous sleeve of plastic film, providing a tight and uniform seal ideal for individual or grouped items, while bundle wrapping groups multiple products together using stretch film, leaving more air space and allowing easier handling of multiple units. Sleeve wrapping offers enhanced protection against dust and moisture with a more polished appearance, whereas bundle wrapping focuses primarily on securing products for transport and storage efficiency. Key differences lie in application methods, protection levels, and suitability for different packaging needs in retail and shipping environments.

Packaging Materials Used in Each Method

Sleeve wrapping primarily uses polyethylene or polypropylene film to tightly encase individual products or groups, offering transparency and protection against dust and moisture. Bundle wrapping involves stretch film or shrink wrap combined with adhesives or tapes to secure multiple items together, enhancing stability during transport. Understanding these packaging materials helps you choose the most suitable option for product protection and efficient handling.

Efficiency and Speed Comparison

Sleeve wrapping offers higher efficiency and faster application compared to bundle wrapping due to its simpler, continuous film design that minimizes material overlap and reduces film usage. Bundle wrapping typically requires more time as it involves manually securing multiple items individually or in small groups, increasing labor and film consumption. Your choice impacts packaging speed, with sleeve wrapping enhancing throughput in high-volume operations.

Application Suitability: When to Use Each Method

Sleeve wrapping is ideal for lightweight products or items that require visibility and easy access, such as beverages and single-unit consumer goods. Bundle wrapping suits heavier or irregularly shaped products that benefit from extra stability and protection during transport, including industrial parts and multi-pack items. Choosing the right method depends on your product's weight, shape, and handling requirements to ensure safe and efficient packaging.

Cost Implications: Sleeve vs Bundle Wrapping

Sleeve wrapping generally incurs lower material and labor costs compared to bundle wrapping due to its simpler application process and reduced use of packaging materials such as shrink film or stretch wrap. Bundle wrapping, while offering enhanced protection and stability for irregularly shaped or heavier items, typically demands higher expenses for additional strapping, heavier films, and more labor-intensive bundling techniques. Choosing between sleeve and bundle wrapping directly impacts packaging budgets by balancing cost efficiency with the level of protection required for the specific product type and handling conditions.

Environmental Impact and Sustainability

Sleeve wrapping typically uses less plastic material compared to bundle wrapping, reducing overall waste and environmental footprint. Bundle wrapping often involves multiple layers and additional packaging components, which can increase resource consumption and hinder recycling efforts. Choosing sleeve wrapping can enhance your sustainability goals by minimizing plastic usage and improving recyclability in packaging processes.

Choosing the Right Wrapping Solution for Your Business

Sleeve wrapping offers a sleek, secure option ideal for individual product protection and improved shelf appeal, while bundle wrapping efficiently groups multiple items for bulk handling and transport. Your choice depends on product type, packaging speed, and desired presentation, with sleeve wrapping enhancing visibility and bundle wrapping optimizing shipping efficiency. Understanding these distinctions ensures your business selects the most effective wrapping solution for operational needs and cost management.

Sleeve wrapping vs bundle wrapping Infographic

libmatt.com

libmatt.com