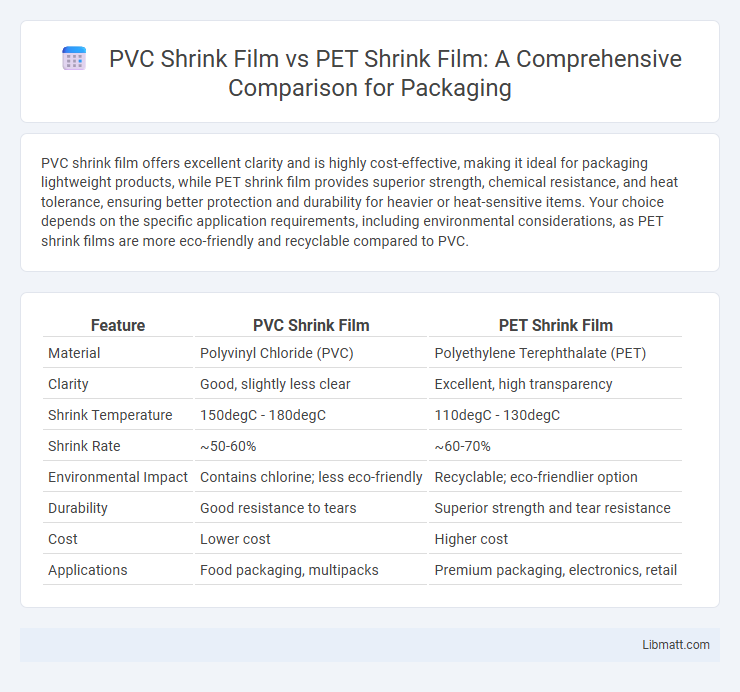

PVC shrink film offers excellent clarity and is highly cost-effective, making it ideal for packaging lightweight products, while PET shrink film provides superior strength, chemical resistance, and heat tolerance, ensuring better protection and durability for heavier or heat-sensitive items. Your choice depends on the specific application requirements, including environmental considerations, as PET shrink films are more eco-friendly and recyclable compared to PVC.

Table of Comparison

| Feature | PVC Shrink Film | PET Shrink Film |

|---|---|---|

| Material | Polyvinyl Chloride (PVC) | Polyethylene Terephthalate (PET) |

| Clarity | Good, slightly less clear | Excellent, high transparency |

| Shrink Temperature | 150degC - 180degC | 110degC - 130degC |

| Shrink Rate | ~50-60% | ~60-70% |

| Environmental Impact | Contains chlorine; less eco-friendly | Recyclable; eco-friendlier option |

| Durability | Good resistance to tears | Superior strength and tear resistance |

| Cost | Lower cost | Higher cost |

| Applications | Food packaging, multipacks | Premium packaging, electronics, retail |

Overview of PVC and PET Shrink Films

PVC shrink film offers excellent clarity, flexibility, and cost-effectiveness, making it a popular choice for packaging lightweight products and promotional materials. PET shrink film provides superior strength, thermal resistance, and environmental benefits due to its recyclability, often preferred for heavier items and food packaging that requires durability. Your selection between PVC and PET shrink films should consider factors like product weight, transparency needs, and sustainability goals.

Material Composition and Properties

PVC shrink film is primarily composed of polyvinyl chloride, offering excellent clarity, flexibility, and a tight shrink performance ideal for irregularly shaped products. PET shrink film, made from polyethylene terephthalate, provides superior tensile strength, high resistance to punctures and tears, and better environmental stability at higher temperatures. The chemical structure of PET allows for a more rigid and thicker film compared to the softer, more pliable nature of PVC, making PET ideal for heavier or sharper-edged items.

Shrinkage Characteristics and Performance

PVC shrink film offers higher shrinkage rates of up to 65-75%, providing excellent conformability to irregular shapes, while PET shrink film typically shrinks between 40-50%, delivering a tighter and more rigid wrap. PVC's faster shrink response makes it ideal for fast packaging lines, whereas PET exhibits superior heat resistance and clarity, maintaining performance under higher temperatures. PET shrink film also demonstrates better tensile strength and puncture resistance, optimizing product protection in demanding environments.

Environmental Impact and Sustainability

PVC shrink film has a higher environmental impact due to the release of toxic chemicals like dioxins and chlorine when incinerated or improperly disposed of, while PET shrink film is more eco-friendly, being recyclable and producing fewer harmful emissions. PET shrink film's sustainability is enhanced by its ability to be recycled multiple times, reducing plastic waste and resource consumption. Choosing PET shrink film for your packaging aligns better with sustainable practices and environmental responsibility.

Printability and Graphics Quality

PVC shrink film offers excellent printability with vibrant colors and sharp graphics, making it ideal for high-impact marketing and branding applications. PET shrink film provides superior clarity and gloss, enhancing graphic detail and creating a premium look that resists fading and smudging. Both films support advanced printing techniques, but PET's higher transparency results in visually striking packaging that elevates product presentation.

Application Versatility and Use Cases

PVC shrink film offers excellent application versatility, commonly used for packaging consumer goods, food products, and printed materials due to its clarity and strong shrink properties. PET shrink film provides superior durability and temperature resistance, making it ideal for heavy-duty packaging, industrial labeling, and products requiring enhanced protection during shipping. Your choice depends on the specific use case, balancing PVC's cost-effectiveness and clarity with PET's strength and performance in demanding environments.

Clarity and Appearance

PVC shrink film offers excellent clarity and a glossy appearance, making it ideal for retail packaging that requires high visual appeal. PET shrink film provides superior optical clarity with enhanced resistance to yellowing and a cleaner, more vibrant look over time. Both materials ensure effective product visibility, but PET excels in maintaining long-lasting clarity and a premium finish.

Cost Comparison and Market Availability

PVC shrink film generally costs less than PET shrink film due to lower production expenses and simpler manufacturing processes. PET shrink film offers superior durability and thermal stability, leading to higher demand in premium packaging markets despite its elevated price. Market availability of PVC shrink film remains widespread because of its affordability, while PET shrink film is increasingly accessible in regions prioritizing eco-friendly and high-performance packaging solutions.

Safety and Regulatory Compliance

PVC shrink film poses greater safety concerns due to the potential release of harmful dioxins and plasticizers during production and incineration, which can lead to stricter regulatory scrutiny and limited use in food packaging. PET shrink film is widely regarded as safer, meeting more stringent FDA and EU food contact regulations thanks to its inert chemical properties and lower environmental impact. Choosing PET shrink film helps ensure your packaging complies with global safety standards and reduces health risks for consumers.

Choosing the Right Shrink Film for Your Needs

PVC shrink film is known for its excellent clarity, flexibility, and cost-effectiveness, making it ideal for packaging irregularly shaped items and providing a tight seal. PET shrink film offers superior strength, higher temperature resistance, and better environmental sustainability, suitable for products requiring durability and eco-friendly packaging. Consider your product's requirements for clarity, strength, and environmental impact to choose the shrink film that best suits your needs.

PVC shrink film vs PET shrink film Infographic

libmatt.com

libmatt.com