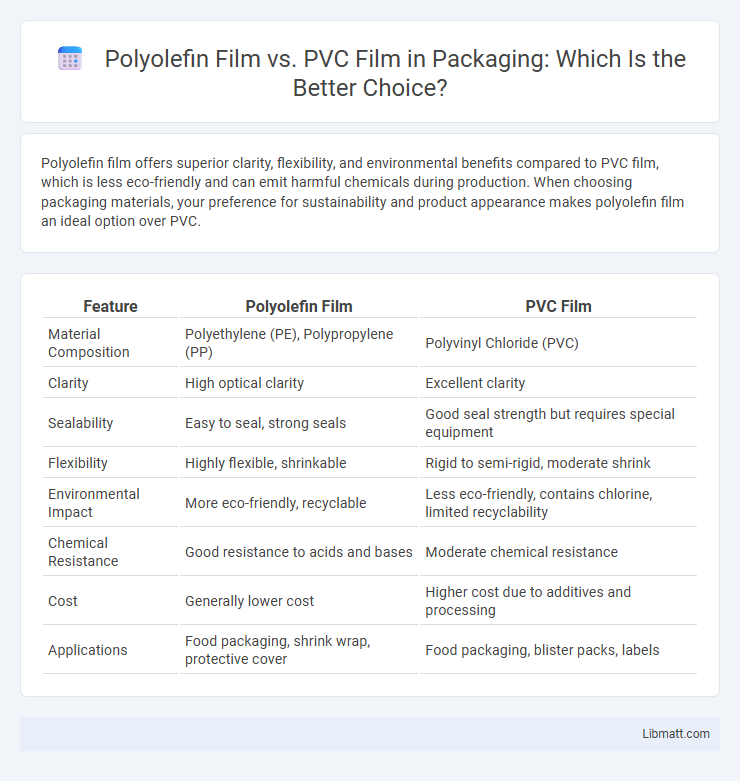

Polyolefin film offers superior clarity, flexibility, and environmental benefits compared to PVC film, which is less eco-friendly and can emit harmful chemicals during production. When choosing packaging materials, your preference for sustainability and product appearance makes polyolefin film an ideal option over PVC.

Table of Comparison

| Feature | Polyolefin Film | PVC Film |

|---|---|---|

| Material Composition | Polyethylene (PE), Polypropylene (PP) | Polyvinyl Chloride (PVC) |

| Clarity | High optical clarity | Excellent clarity |

| Sealability | Easy to seal, strong seals | Good seal strength but requires special equipment |

| Flexibility | Highly flexible, shrinkable | Rigid to semi-rigid, moderate shrink |

| Environmental Impact | More eco-friendly, recyclable | Less eco-friendly, contains chlorine, limited recyclability |

| Chemical Resistance | Good resistance to acids and bases | Moderate chemical resistance |

| Cost | Generally lower cost | Higher cost due to additives and processing |

| Applications | Food packaging, shrink wrap, protective cover | Food packaging, blister packs, labels |

Introduction to Polyolefin and PVC Films

Polyolefin film, made from polyethylene or polypropylene, offers excellent clarity, flexibility, and moisture resistance, making it ideal for food packaging and shrink-wrapping applications. PVC film, derived from polyvinyl chloride, provides superior durability and chemical resistance but can release harmful additives, making it less suitable for direct food contact. Understanding the differences in material properties helps you choose the right film for your packaging needs.

Chemical Composition and Structure

Polyolefin film consists primarily of polymers like polyethylene or polypropylene, offering a non-polar, inert, and semi-crystalline structure that provides superior chemical resistance and flexibility. PVC film is made from polyvinyl chloride, featuring chlorine atoms in its polymer chain, resulting in a more rigid, polar, and dense structure with inherent flame retardancy and strength. Your choice between these films impacts chemical compatibility, durability, and application performance based on their distinct molecular compositions.

Manufacturing Processes

Polyolefin film manufacturing involves extrusion and biaxial orientation, resulting in a lightweight, flexible film with excellent clarity and chemical resistance. PVC film production uses calendaring or extrusion techniques, often incorporating plasticizers to enhance flexibility but potentially compromising environmental safety. Choosing polyolefin film supports more sustainable manufacturing processes and offers improved durability for Your packaging needs.

Physical and Mechanical Properties

Polyolefin film exhibits superior tensile strength and elongation compared to PVC film, making it more resistant to tearing and punctures. Its lower density results in a lighter material with improved flexibility, while PVC film is generally stiffer but offers better clarity and moisture barrier properties. Polyolefin films also demonstrate enhanced heat sealability and environmental resistance, contributing to their versatility in packaging applications versus the more rigid and chemically stable PVC films.

Clarity and Appearance

Polyolefin film offers superior clarity and a glossy appearance, making it ideal for high-quality packaging where product visibility is essential. PVC film tends to have a slightly lower clarity with a more matte finish, which may affect the overall presentation of your packaged goods. Choosing polyolefin enhances the visual appeal and ensures your products stand out on the shelf.

Environmental Impact and Sustainability

Polyolefin film offers a significantly lower environmental impact compared to PVC film due to its recyclable nature and absence of harmful chlorine compounds that contribute to dioxin pollution during disposal. PVC film releases toxic chemicals and requires more energy-intensive manufacturing processes, making it less sustainable for long-term use. Choosing polyolefin film supports Your commitment to eco-friendly packaging by reducing landfill waste and promoting circular economy practices.

Applications in Packaging Industry

Polyolefin film is widely used in food packaging due to its excellent moisture barrier, heat sealability, and clarity, making it ideal for wrapping fresh produce, bakery items, and frozen foods. PVC film is favored for shrink wrapping and blister packaging because of its rigidity, transparency, and cost-effectiveness, commonly applied in pharmaceutical packaging and retail product displays. Both films offer distinct advantages, with polyolefin preferred for food safety and flexibility, while PVC provides superior strength and visual appeal in protective packaging.

Cost Comparison and Economic Factors

Polyolefin film generally offers a more cost-effective solution compared to PVC film due to lower raw material and processing expenses, making it favorable for budget-sensitive packaging applications. PVC film often incurs higher costs linked to its chemical composition and environmental compliance requirements, such as chlorine content and recycling challenges. Economic factors like durability, recyclability, and regulatory restrictions further influence the overall cost efficiency, positioning polyolefin films as more sustainable and economical over the long term.

Safety and Regulatory Compliance

Polyolefin films are favored for safety and regulatory compliance due to their non-toxic, BPA-free composition and lower risk of harmful chemical leaching compared to PVC films, which often contain phthalates and chlorine-related compounds. Polyolefin films meet stringent food contact regulations such as FDA and EU standards, offering safer alternatives for packaging applications. PVC films face increasing regulatory scrutiny and restrictions because of their environmental impact and potential health risks associated with plasticizers and dioxin formation during production and disposal.

Market Trends and Future Outlook

Polyolefin film is experiencing rapid growth due to its eco-friendly properties, recyclability, and increasing demand in food packaging, surpassing PVC film, which faces regulatory restrictions because of its chlorine content. Market trends indicate a strong shift toward sustainable materials, with polyolefin films capturing larger market shares in regions prioritizing environmental compliance, such as Europe and North America. Your business can benefit by investing in polyolefin film technologies that align with future consumer preferences and emerging regulatory standards.

Polyolefin film vs PVC film Infographic

libmatt.com

libmatt.com