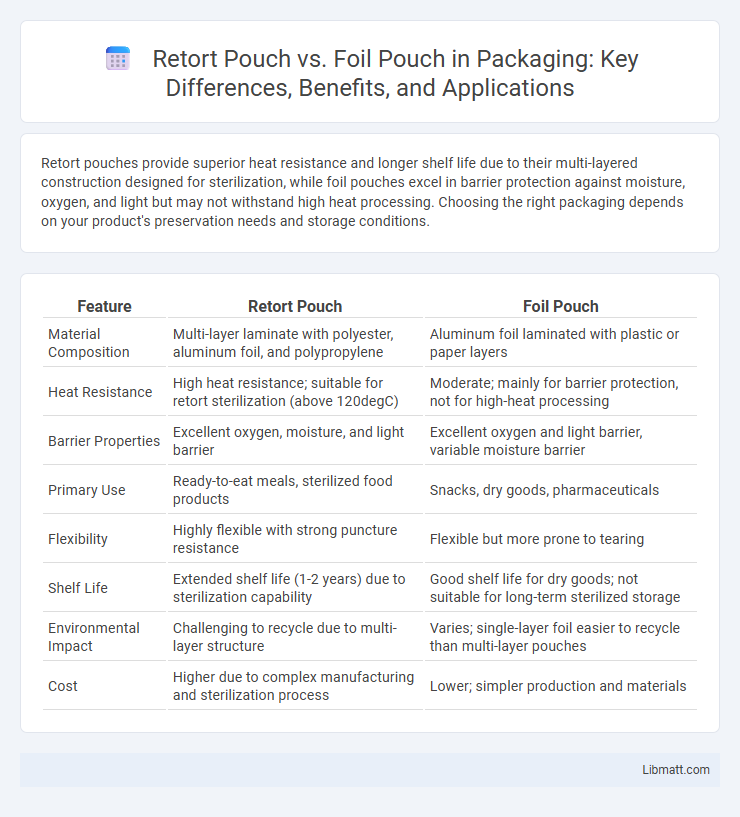

Retort pouches provide superior heat resistance and longer shelf life due to their multi-layered construction designed for sterilization, while foil pouches excel in barrier protection against moisture, oxygen, and light but may not withstand high heat processing. Choosing the right packaging depends on your product's preservation needs and storage conditions.

Table of Comparison

| Feature | Retort Pouch | Foil Pouch |

|---|---|---|

| Material Composition | Multi-layer laminate with polyester, aluminum foil, and polypropylene | Aluminum foil laminated with plastic or paper layers |

| Heat Resistance | High heat resistance; suitable for retort sterilization (above 120degC) | Moderate; mainly for barrier protection, not for high-heat processing |

| Barrier Properties | Excellent oxygen, moisture, and light barrier | Excellent oxygen and light barrier, variable moisture barrier |

| Primary Use | Ready-to-eat meals, sterilized food products | Snacks, dry goods, pharmaceuticals |

| Flexibility | Highly flexible with strong puncture resistance | Flexible but more prone to tearing |

| Shelf Life | Extended shelf life (1-2 years) due to sterilization capability | Good shelf life for dry goods; not suitable for long-term sterilized storage |

| Environmental Impact | Challenging to recycle due to multi-layer structure | Varies; single-layer foil easier to recycle than multi-layer pouches |

| Cost | Higher due to complex manufacturing and sterilization process | Lower; simpler production and materials |

Introduction to Retort and Foil Pouches

Retort pouches are flexible packaging made from multi-layer laminated films designed to withstand high-temperature sterilization processes, ensuring extended shelf life for ready-to-eat meals. Foil pouches consist primarily of aluminum foil layers that provide excellent barrier properties against moisture, oxygen, and light, commonly used for sensitive products like coffee and pharmaceuticals. Both packaging types offer durability and protection but differ significantly in heat resistance and product compatibility.

Material Composition and Structure

Retort pouches consist of multiple layers, including a polyester outer layer for printability, an aluminum foil layer for gas and moisture barrier, and a polypropylene inner layer for heat sealing and food safety. Foil pouches primarily feature an aluminum foil core sandwiched between protective films, providing excellent protection against light, oxygen, and moisture. Understanding the material composition and structure helps you select the ideal packaging for shelf stability and product preservation.

Packaging Process Comparison

Retort pouches undergo a sterilization process involving high temperature and pressure, ensuring food safety and extended shelf life, while foil pouches primarily focus on barrier protection without sterilization. The retort packaging process includes filling, sealing, and retorting, which subjects the pouch to thermal processing, unlike foil pouches that are sealed after packaging and often require refrigeration. Retort pouches offer convenience in processing and storage by combining flexible packaging with the ability to withstand autoclave conditions, whereas foil pouches rely on their material properties for protection but lack heat sterilization compatibility.

Barrier Properties: Shelf Life and Preservation

Retort pouches offer superior barrier properties against oxygen, moisture, and light due to their multi-layered construction, enhancing shelf life and preservation of food products. Foil pouches also provide excellent barrier protection but may be more prone to punctures and less flexible during thermal processing, potentially affecting longevity. Both pouches extend shelf life significantly compared to traditional packaging, but retort pouches excel in maintaining food quality through sterilization and hermetic sealing.

Heat Resistance and Sterilization Methods

Retort pouches offer superior heat resistance due to their multi-layer laminated structure, enabling effective steam sterilization at temperatures up to 121degC without compromising packaging integrity. Foil pouches, while providing excellent barrier properties, generally withstand lower temperatures and are more suitable for sterilization methods such as dry heat or lower-temperature processes. Your choice depends on the required sterilization technique and the thermal durability needed for safe and effective food preservation.

Environmental Impact and Sustainability

Retort pouches have a lower environmental impact compared to foil pouches due to their lighter weight and reduced material usage, leading to decreased transportation emissions and less waste in landfills. The production process of retort pouches typically consumes less energy and water, enhancing their sustainability profile. Recycling challenges remain for both types, but innovations in recyclable retort materials are improving their eco-friendliness relative to traditional foil pouches.

Cost Analysis: Manufacturing and Logistics

Retort pouches typically offer lower manufacturing costs due to their lightweight, flexible design, which reduces material usage and energy consumption compared to foil pouches. In logistics, retort pouches provide cost advantages through decreased shipping expenses since they occupy less space and weigh significantly less than traditional foil packaging. Your choice between retort and foil pouches should consider these cost factors alongside product protection requirements to optimize overall efficiency.

Common Applications in the Food Industry

Retort pouches are widely used for ready-to-eat meals, soups, and sauces due to their high heat resistance and extended shelf life, while foil pouches are preferred for snacks, coffee, and dehydrated products because of their excellent barrier properties against moisture and oxygen. The choice between retort and foil pouches depends on the specific food product requirements, including preservation needs and processing methods. Your product's stability and packaging efficiency can be optimized by selecting the appropriate pouch type tailored to its application.

Consumer Convenience and Usability

Retort pouches offer enhanced consumer convenience with lightweight, flexible packaging that is easy to carry and store compared to traditional foil pouches. Their resealable options and ability to withstand high-temperature sterilization allow for longer shelf life without refrigeration, making them ideal for on-the-go use. Your choice between retort and foil pouches can significantly impact usability, especially in terms of portability and ease of opening.

Choosing the Right Pouch for Your Product

Retort pouches offer superior heat resistance and extended shelf life for ready-to-eat meals, while foil pouches excel in barrier properties against light, oxygen, and moisture, preserving freshness for snacks and pharmaceuticals. Selecting the right pouch depends on product requirements such as thermal processing needs, shelf stability, and protection from environmental factors. Consider product type, processing methods, and storage conditions to optimize packaging performance and maintain quality throughout distribution.

Retort pouch vs foil pouch Infographic

libmatt.com

libmatt.com