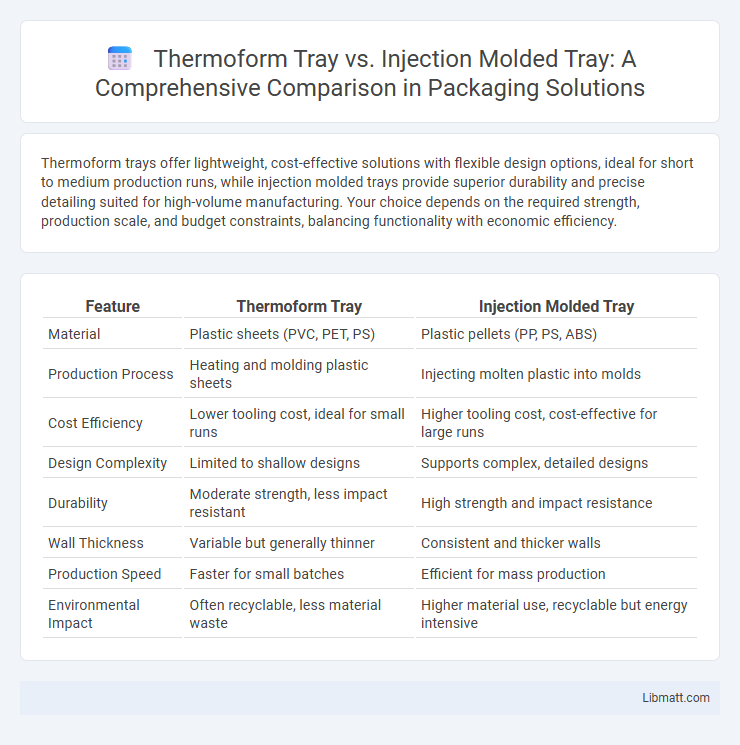

Thermoform trays offer lightweight, cost-effective solutions with flexible design options, ideal for short to medium production runs, while injection molded trays provide superior durability and precise detailing suited for high-volume manufacturing. Your choice depends on the required strength, production scale, and budget constraints, balancing functionality with economic efficiency.

Table of Comparison

| Feature | Thermoform Tray | Injection Molded Tray |

|---|---|---|

| Material | Plastic sheets (PVC, PET, PS) | Plastic pellets (PP, PS, ABS) |

| Production Process | Heating and molding plastic sheets | Injecting molten plastic into molds |

| Cost Efficiency | Lower tooling cost, ideal for small runs | Higher tooling cost, cost-effective for large runs |

| Design Complexity | Limited to shallow designs | Supports complex, detailed designs |

| Durability | Moderate strength, less impact resistant | High strength and impact resistance |

| Wall Thickness | Variable but generally thinner | Consistent and thicker walls |

| Production Speed | Faster for small batches | Efficient for mass production |

| Environmental Impact | Often recyclable, less material waste | Higher material use, recyclable but energy intensive |

Introduction to Thermoform and Injection Molded Trays

Thermoform trays are created by heating a plastic sheet until pliable and then forming it over a mold, resulting in lightweight, cost-effective packaging often used for food and medical supplies. Injection molded trays involve injecting molten plastic into a mold cavity, producing durable, high-precision trays suitable for heavier or more complex items. Understanding the differences in manufacturing methods helps you select the right tray type based on strength, detail, and budget requirements.

Manufacturing Processes: Thermoforming vs Injection Molding

Thermoform trays are created by heating a plastic sheet until pliable, then shaping it over a mold using vacuum or pressure, enabling rapid prototyping and cost-effective tooling. Injection molded trays involve injecting molten plastic into a precise mold cavity under high pressure, producing complex geometries with high strength and consistent thickness. Thermoforming typically offers faster cycle times and lower initial tooling costs, while injection molding delivers superior structural integrity and scalability for mass production.

Material Options for Each Tray Type

Thermoform trays typically use flexible materials like PET, PVC, and polystyrene, which allow for lightweight, cost-effective packaging with moderate durability. Injection molded trays often employ more rigid materials such as polypropylene, ABS, and high-impact polystyrene, offering superior strength and heat resistance for heavy-duty applications. Material selection depends on required durability, production volume, and specific product protection needs.

Cost Comparison: Initial Investment and Production

Thermoform trays typically require lower initial investment costs due to simpler tooling and mold fabrication, making them more cost-effective for small to medium production runs. Injection molded trays involve higher upfront expenses for creating complex molds but offer lower per-unit costs and faster production rates at larger volumes. Choosing between thermoforming and injection molding depends on balancing initial tool costs with anticipated production scale and unit cost efficiency.

Design Flexibility and Customization

Thermoform trays offer greater design flexibility with the ability to create complex shapes, contours, and detailed textures tailored to your specific packaging needs. Injection molded trays, while providing higher durability and precision, are limited by mold design constraints and typically involve higher upfront tooling costs, making them less adaptable for frequent customization. Choosing between the two depends on your priorities for unique design features versus production efficiency and part strength.

Performance and Durability Differences

Thermoform trays exhibit flexibility and lower cost production but generally have reduced structural strength and durability compared to injection molded trays. Injection molded trays deliver superior impact resistance and dimensional stability, making them ideal for heavy-duty applications requiring long-term durability. Performance-wise, injection molded trays maintain integrity under repeated use and harsh conditions, whereas thermoform trays are better suited for lightweight, disposable, or short-term usage scenarios.

Environmental Impact and Sustainability

Thermoform trays typically have a lower environmental footprint due to reduced energy consumption during manufacturing and the ability to use thinner plastic sheets, resulting in less raw material usage and waste. Injection molded trays, while often more durable and reusable, require higher energy inputs and generate more plastic scrap, impacting sustainability negatively if not recycled effectively. Both manufacturing processes can improve sustainability by incorporating recycled plastics and optimizing product design to minimize environmental impact.

Applications and Industry Usage

Thermoform trays are widely used in the food packaging industry for products like fresh produce, bakery items, and ready meals due to their cost-effectiveness and flexibility in design. Injection molded trays find extensive application in the pharmaceutical and electronics industries because of their superior durability and precision in holding delicate components. Both manufacturing methods cater to varying production volumes and customization needs, with thermoforming suited for high-volume, lightweight packaging, while injection molding supports intricate designs and long-term reuse.

Pros and Cons: Thermoform Trays

Thermoform trays offer lightweight construction and cost-effective production for short to medium runs, making them ideal for customizable packaging needs. They provide excellent clarity and design flexibility but generally have lower structural strength and durability compared to injection molded trays. Your choice depends on balancing budget constraints and the required rigidity for your product's protection.

Pros and Cons: Injection Molded Trays

Injection molded trays offer high durability and precision, making them ideal for applications requiring detailed features and robust strength. They generally have a higher upfront tooling cost but enable faster production rates and consistent quality for large volumes. However, these trays lack design flexibility compared to thermoform trays and may involve longer lead times due to complex mold creation.

Thermoform tray vs injection molded tray Infographic

libmatt.com

libmatt.com