Push-pull caps offer a secure seal that prevents leaks and dispensing mess, making them ideal for beverages and liquid products you frequently use on the go. Flip-top caps provide easy one-handed access and quick opening, perfect for products requiring controlled pouring or squeezing, enhancing convenience and user experience.

Table of Comparison

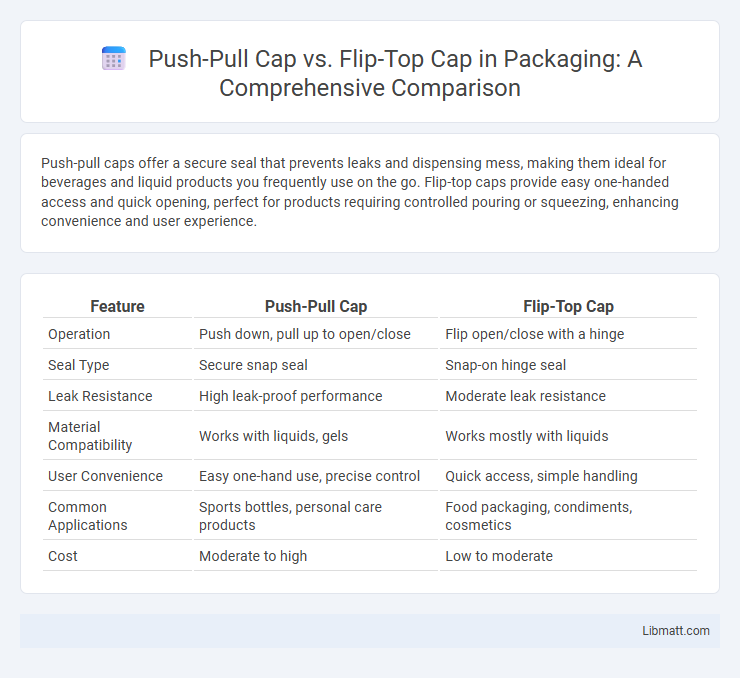

| Feature | Push-Pull Cap | Flip-Top Cap |

|---|---|---|

| Operation | Push down, pull up to open/close | Flip open/close with a hinge |

| Seal Type | Secure snap seal | Snap-on hinge seal |

| Leak Resistance | High leak-proof performance | Moderate leak resistance |

| Material Compatibility | Works with liquids, gels | Works mostly with liquids |

| User Convenience | Easy one-hand use, precise control | Quick access, simple handling |

| Common Applications | Sports bottles, personal care products | Food packaging, condiments, cosmetics |

| Cost | Moderate to high | Low to moderate |

Introduction to Cap Types: Push-Pull vs Flip-Top

Push-pull caps offer a secure, user-friendly dispensing mechanism ideal for controlling liquid flow in bottles, making them perfect for products requiring precise application. Flip-top caps provide quick access and resealing convenience, commonly used for products that need frequent opening and closing without unscrewing. Your choice between push-pull and flip-top caps depends on the product's usage frequency, viscosity, and user experience preferences.

Design Overview: Push-Pull Cap

Push-pull caps feature a simple yet effective design that allows you to open and close the container by pulling up or pushing down the nozzle, ensuring quick access and secure sealing. Their ergonomic structure minimizes spillage and is commonly used for liquid products like shampoos, lotions, and condiments. Compared to flip-top caps, push-pull caps often provide a more controlled dispensing experience, enhancing convenience and customer satisfaction.

Design Overview: Flip-Top Cap

The flip-top cap features a hinged lid that snaps securely over the dispensing opening, providing a convenient one-handed operation and reducing the risk of spillage. Its ergonomic design supports quick access while maintaining product freshness and hygiene by preventing contaminants from entering. You benefit from the flip-top cap's user-friendly mechanism that enhances the overall packaging experience for daily-use products.

Usability Comparison: Ease of Opening and Closing

Push-pull caps offer a straightforward mechanism that allows users to easily open and close the container with one hand, making them ideal for quick access and on-the-go use. Flip-top caps feature a hinged lid that snaps securely into place, providing a reliable seal while allowing for effortless single-handed operation. Both caps excel in usability, but push-pull caps generally provide faster access, while flip-top caps ensure a more secure closure.

Leak-Proof Performance and Security

Push-pull caps offer superior leak-proof performance due to their secure sealing mechanism, which minimizes the risk of accidental spills, making them ideal for active or travel use. Flip-top caps provide quick access but may be more prone to leakage if not properly closed, potentially compromising the security of your contents. For maximum protection against leaks, especially during transport, the push-pull cap ensures your liquid stays contained and secure.

Hygiene and Contamination Risks

Push-pull caps reduce contamination risks by minimizing direct contact with the dispensing nozzle, enhancing hygiene during use. Flip-top caps can expose the product to environmental contaminants more easily since the opening is uncovered when flipped. Your choice between these caps impacts the level of protection against germs and ensures safer product handling.

Material Durability and Longevity

Push-pull caps are typically made from robust polyethylene or polypropylene, offering excellent material durability and resistance to wear, making them ideal for repeated use over time. Flip-top caps, often constructed from similar plastics but sometimes incorporating thinner hinge mechanisms, may experience faster wear or breakage under frequent opening. Choosing the right cap ensures your packaging maintains longevity and functionality throughout the product's lifecycle.

Application Suitability: Product and Industry Uses

Push-pull caps are ideal for liquid products requiring controlled, hygienic dispensing such as shampoos, conditioners, and liquid soaps frequently used in personal care and household cleaning industries. Flip-top caps suit thicker substances like lotions, creams, and gels, making them common in cosmetics, skincare, and pharmaceutical packaging where easy one-handed access is important. Both cap types enhance user convenience but are selected based on product viscosity, dispensing precision, and industry-specific hygiene standards.

Environmental Impact and Recyclability

Push-pull caps typically use less plastic than flip-top caps, reducing material waste and environmental footprint. Flip-top caps often have more complex designs that can complicate recycling processes and lead to lower recyclability rates. Choosing the right cap can enhance your packaging sustainability by minimizing plastic usage and improving recycling efficiency.

Choosing the Right Cap for Your Needs

Push-pull caps offer secure, leak-resistant closures ideal for beverages, promoting controlled dispensing and hygiene. Flip-top caps provide quick, easy access and convenience, often favored for products like shampoos and lotions that require frequent opening. Selecting the right cap depends on product viscosity, usage frequency, and user convenience preferences to ensure optimal functionality and customer satisfaction.

Push-pull cap vs flip-top cap Infographic

libmatt.com

libmatt.com