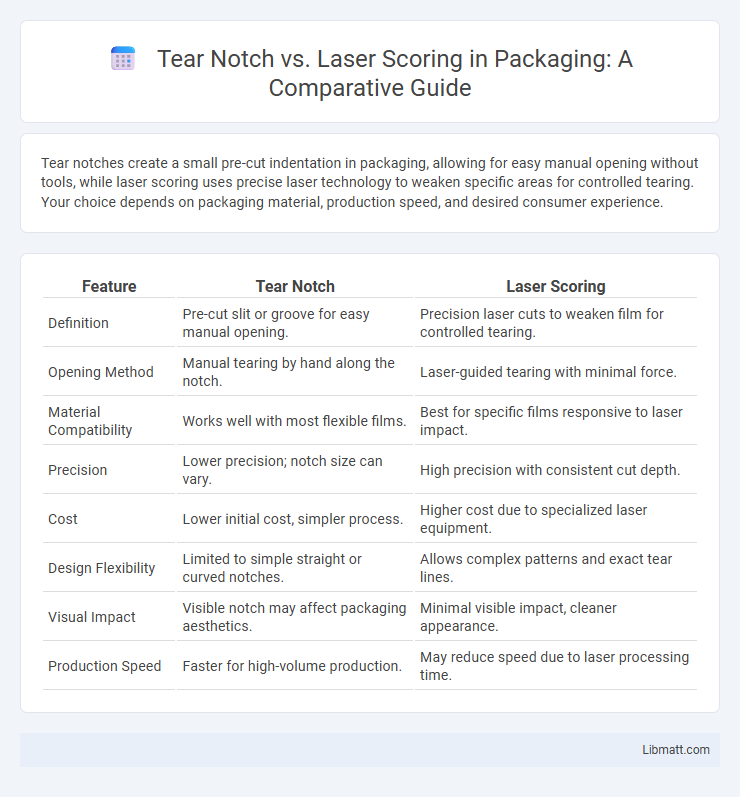

Tear notches create a small pre-cut indentation in packaging, allowing for easy manual opening without tools, while laser scoring uses precise laser technology to weaken specific areas for controlled tearing. Your choice depends on packaging material, production speed, and desired consumer experience.

Table of Comparison

| Feature | Tear Notch | Laser Scoring |

|---|---|---|

| Definition | Pre-cut slit or groove for easy manual opening. | Precision laser cuts to weaken film for controlled tearing. |

| Opening Method | Manual tearing by hand along the notch. | Laser-guided tearing with minimal force. |

| Material Compatibility | Works well with most flexible films. | Best for specific films responsive to laser impact. |

| Precision | Lower precision; notch size can vary. | High precision with consistent cut depth. |

| Cost | Lower initial cost, simpler process. | Higher cost due to specialized laser equipment. |

| Design Flexibility | Limited to simple straight or curved notches. | Allows complex patterns and exact tear lines. |

| Visual Impact | Visible notch may affect packaging aesthetics. | Minimal visible impact, cleaner appearance. |

| Production Speed | Faster for high-volume production. | May reduce speed due to laser processing time. |

Introduction: Tear Notch vs Laser Scoring

Tear notch creates a simple, mechanical indentation in packaging materials to facilitate easy opening without specialized equipment. Laser scoring uses precise laser technology to cut or weaken specific areas, enabling clean, controlled tearing with enhanced design flexibility. Both methods improve user experience by providing optimized tear points but differ significantly in cost, precision, and application complexity.

Understanding Tear Notch Technology

Tear notch technology creates a precise indentation on packaging films to facilitate easy opening without compromising product integrity. Unlike laser scoring, which uses controlled laser beams to weaken specific areas, tear notches physically alter the film's structure to guide tear direction. This mechanical method enhances user convenience while maintaining packaging strength and barrier properties.

Fundamentals of Laser Scoring

Laser scoring uses a focused beam to create precise, controlled grooves on packaging materials, allowing for clean and easy tearing along designated lines. This technique ensures consistent depth and width of the score, enhancing packaging functionality without compromising strength. Your packaging benefits from improved aesthetics and user convenience through the precision and reliability of laser scoring compared to traditional tear notches.

Material Compatibility: Tear Notch vs Laser Scoring

Tear notch offers excellent compatibility with a wide range of flexible materials, including polyethylene, polypropylene, and laminated films, making it ideal for packaging requiring controlled mechanical openings. Laser scoring provides precise, customizable incisions suitable for various substrates such as plastic films, paper, and foil, but performance may vary with multi-layer or heat-sensitive materials due to thermal effects. Understanding the material's composition and thickness is vital in choosing between tear notch's mechanical approach and laser scoring's thermal process to ensure clean, reliable package openings.

Precision and Consistency Comparison

Laser scoring offers higher precision and consistency compared to tear notches by creating clean, uniform lines that ensure controlled and easy tearing. Tear notches may vary due to manual or mechanical inconsistencies, which can affect the reliability of the tearing process. Your packaging will benefit from laser scoring when accuracy and repeatability are critical for maintaining product integrity and enhancing user experience.

Impact on Packaging Integrity

Tear notch and laser scoring both affect packaging integrity by controlling the opening force and reducing the risk of accidental damage. Tear notches create a mechanical weak point that ensures consistent package opening while maintaining structural strength, especially in flexible films. Laser scoring offers precise and customizable weakening patterns that minimize stress concentration, preserving overall package durability and preventing leaks or contamination.

Cost Analysis: Tear Notch vs Laser Scoring

Tear notches typically offer a lower upfront cost compared to laser scoring, making them a budget-friendly option for businesses with high-volume packaging needs. However, laser scoring provides precise, consistent cuts that can reduce waste and improve product presentation, potentially lowering long-term expenses. Your choice should weigh initial investment against efficiency gains to optimize overall cost-effectiveness.

Consumer Experience and Convenience

Tear notch packaging offers consumers a straightforward, tactile method to open products without the need for tools, enhancing convenience and reducing frustration. Laser scoring creates a precise, controlled opening that maintains package integrity while allowing effortless access, appealing to consumers who value neatness and reliability. Both techniques improve user experience by balancing ease of use with packaging durability, though tear notches excel in tactile feedback and laser scoring excels in precision.

Sustainability and Environmental Considerations

Tear notch and laser scoring both impact packaging sustainability through material efficiency and recyclability. Tear notches reduce plastic waste by enabling easier, precise openings without additional tools, promoting consumer convenience and reducing damaged packaging. Laser scoring offers cleaner cuts that facilitate material recycling by minimizing contamination and enabling thinner, lighter packaging designs that lower carbon footprints.

Choosing the Right Method for Your Application

Selecting between tear notch and laser scoring depends on the specific packaging requirements and material type. Tear notches are ideal for flexible films that need easy manual opening, providing controlled tear initiation without compromising package integrity. Laser scoring offers precise, clean cuts suitable for high-volume production and complex designs, ensuring consistent opening performance in rigid or multilayer substrates.

Tear notch vs laser scoring Infographic

libmatt.com

libmatt.com