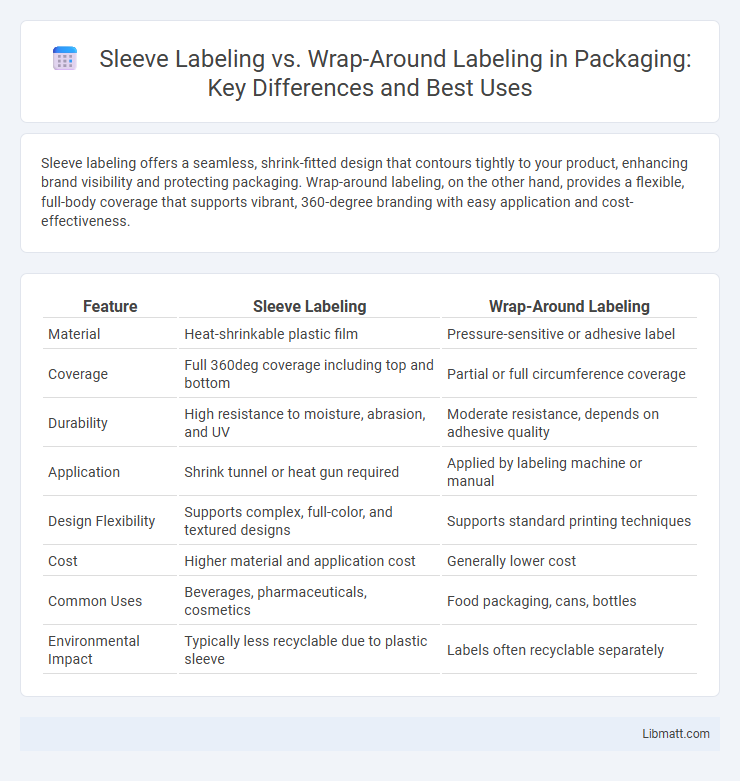

Sleeve labeling offers a seamless, shrink-fitted design that contours tightly to your product, enhancing brand visibility and protecting packaging. Wrap-around labeling, on the other hand, provides a flexible, full-body coverage that supports vibrant, 360-degree branding with easy application and cost-effectiveness.

Table of Comparison

| Feature | Sleeve Labeling | Wrap-Around Labeling |

|---|---|---|

| Material | Heat-shrinkable plastic film | Pressure-sensitive or adhesive label |

| Coverage | Full 360deg coverage including top and bottom | Partial or full circumference coverage |

| Durability | High resistance to moisture, abrasion, and UV | Moderate resistance, depends on adhesive quality |

| Application | Shrink tunnel or heat gun required | Applied by labeling machine or manual |

| Design Flexibility | Supports complex, full-color, and textured designs | Supports standard printing techniques |

| Cost | Higher material and application cost | Generally lower cost |

| Common Uses | Beverages, pharmaceuticals, cosmetics | Food packaging, cans, bottles |

| Environmental Impact | Typically less recyclable due to plastic sleeve | Labels often recyclable separately |

Understanding Sleeve Labeling Techniques

Sleeve labeling techniques involve applying a shrinkable plastic film tightly around a product, offering 360-degree coverage and customizable design options, which enhances brand visibility and protection. Wrap-around labeling uses adhesive labels wrapped around the container's circumference, providing a cost-effective solution but limited design space compared to sleeve labels. Understanding these methods helps you choose the optimal labeling approach based on packaging needs, product shape, and branding goals.

What is Wrap-Around Labeling?

Wrap-around labeling is a packaging technique where a label completely encircles a container, providing 360-degree branding and product information. This method ensures maximum visibility and a seamless appearance, ideal for bottles, cans, and jars. If you want to enhance your product's shelf appeal, wrap-around labeling offers a durable and versatile solution.

Material Choices for Sleeve and Wrap-Around Labels

Sleeve labeling typically utilizes shrinkable materials like PET, PVC, or OPS films that conform tightly to container shapes, offering vibrant full-body coverage and durability. Wrap-around labeling often employs paper or polypropylene films, balancing cost-effectiveness with moderate resistance to moisture and wear, ideal for cylindrical containers. Your choice of material impacts label performance, print quality, and application method for both sleeve and wrap-around labels.

Visual Appeal: Design and Flexibility Comparison

Sleeve labeling offers superior visual appeal through 360-degree design coverage, allowing vibrant, seamless graphics that fully conform to container shapes, enhancing product visibility. Wrap-around labeling provides strong design flexibility but is typically limited to cylindrical containers, restricting the label's shape and print area compared to sleeve labels. The shrink-fit nature of sleeve labels creates a smooth, tamper-evident finish that elevates aesthetic quality beyond the overlapping seams common in wrap-around labels.

Application Process: Sleeve vs Wrap-Around

Sleeve labeling involves heat-shrinking a pre-cut plastic sleeve over the product, providing full 360-degree coverage that conforms tightly to the container's shape. Wrap-around labeling applies a pressure-sensitive adhesive label or a glue-applied paper label that wraps around a portion of the container, typically covering only the body without fully encasing it. Your choice between these methods depends on the product's shape, surface texture, and desired durability of the label during handling and exposure.

Cost Considerations in Labeling Methods

Sleeve labeling generally incurs higher material and equipment costs due to the complexity of the shrink sleeve application process and the need for specialized machinery. Wrap-around labeling tends to be more cost-effective, with lower label material expenses and faster application speeds, making it suitable for large-scale production runs. Choosing the right method depends on your budget constraints and desired production efficiency.

Durability and Performance on Shelves

Sleeve labeling offers exceptional durability due to its full-body coverage and resistance to moisture, abrasion, and temperature changes, ensuring vibrant graphics remain intact on shelves. Wrap-around labeling provides strong adhesion and seamless branding around the container but may be more susceptible to edge wear and peeling over time. Your choice depends on the desired shelf impact and environmental exposure, with sleeve labels generally delivering superior performance in demanding retail conditions.

Sustainability and Environmental Impact

Sleeve labeling uses shrink sleeves made from plastic films, which often pose challenges for recycling and contribute to environmental waste, whereas wrap-around labeling typically employs paper-based materials that are more easily recyclable and biodegradable. Your choice impacts sustainability, as wrap-around labels tend to have a smaller carbon footprint due to lower energy consumption during production and reduced plastic waste. Selecting eco-friendly wrap-around labeling supports better environmental stewardship by minimizing landfill contributions and preserving natural resources.

Industry Suitability: Choosing the Right Label

Sleeve labeling excels in industries requiring full 360-degree coverage and vibrant design, making it ideal for beverages, cosmetics, and pharmaceuticals where brand visibility matters. Wrap-around labeling suits mass production in food and beverage sectors due to its cost-effectiveness and streamlined application on cylindrical containers. Understanding your product's shape and marketing goals will help you choose the label type that enhances shelf appeal and meets industry standards.

Future Trends in Packaging Label Technologies

Sleeve labeling and wrap-around labeling continue to evolve with advancements in smart packaging technologies, including the integration of QR codes and NFC for enhanced consumer engagement and product authenticity. Innovations in eco-friendly materials and digital printing techniques are set to improve sustainability and customization in both labeling methods. Your choice between sleeve and wrap-around labels will increasingly depend on the demand for interactive features and environmental impact in future packaging solutions.

Sleeve labeling vs wrap-around labeling Infographic

libmatt.com

libmatt.com