Pre-applied tape ensures consistent adhesion and saves time by eliminating the need for manual taping, reducing the risk of errors and uneven application. Your projects benefit from enhanced efficiency and a cleaner finish compared to the variability of manual taping.

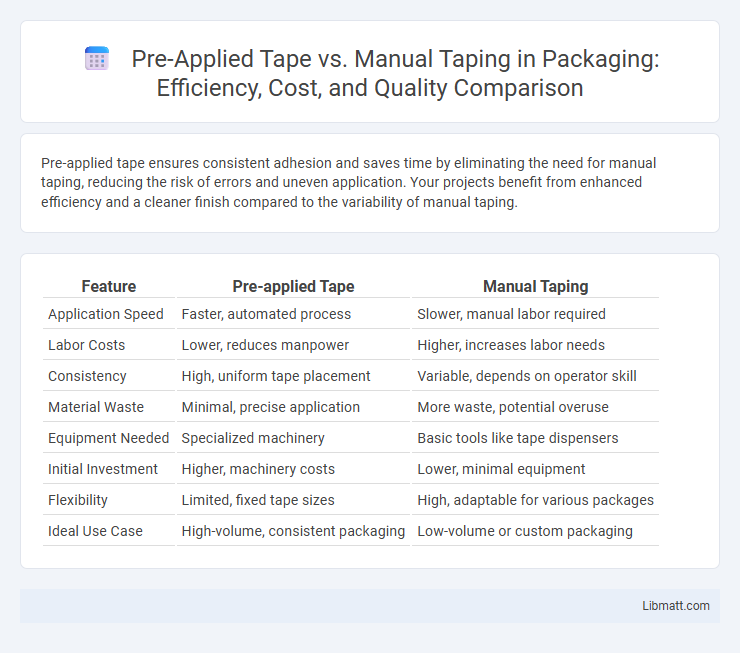

Table of Comparison

| Feature | Pre-applied Tape | Manual Taping |

|---|---|---|

| Application Speed | Faster, automated process | Slower, manual labor required |

| Labor Costs | Lower, reduces manpower | Higher, increases labor needs |

| Consistency | High, uniform tape placement | Variable, depends on operator skill |

| Material Waste | Minimal, precise application | More waste, potential overuse |

| Equipment Needed | Specialized machinery | Basic tools like tape dispensers |

| Initial Investment | Higher, machinery costs | Lower, minimal equipment |

| Flexibility | Limited, fixed tape sizes | High, adaptable for various packages |

| Ideal Use Case | High-volume, consistent packaging | Low-volume or custom packaging |

Introduction to Drywall Taping Methods

Pre-applied tape streamlines drywall finishing by integrating tape with joint compound, reducing labor time and minimizing cracks compared to manual taping, which requires separate application of tape and compound. Manual taping offers greater flexibility and control for complex joints but is more labor-intensive and prone to human error. Advances in pre-applied taping technology enhance consistency and durability, making it an efficient choice for large-scale drywall projects.

What is Pre-Applied Tape?

Pre-applied tape is a factory-applied adhesive strip integrated into drywall joint compound for expedited drywall finishing, reducing manual labor and drying time. This method ensures consistent tape placement and strong seam bonding, enhancing overall project efficiency and quality. Compared to manual taping, pre-applied tape minimizes the risk of air bubbles and misalignment, streamlining the drywall installation process.

Understanding Manual Taping Techniques

Manual taping techniques require precise hand skills and attention to detail to ensure secure and effective sealing of surfaces. You must carefully measure, cut, and apply tape, maintaining consistent pressure to avoid air bubbles and wrinkles that compromise adhesion. Mastery of these techniques enhances durability and protection compared to pre-applied tape, which sacrifices customization for convenience.

Installation Speed: Pre-Applied vs Manual Taping

Pre-applied tape significantly accelerates installation speed by eliminating the need for manual taping during drywall finishing, reducing labor time by up to 40%. Manual taping requires surface preparation, precise application, and drying time, often extending project timelines. Pre-applied tape ensures consistent adhesion and quicker drying, improving overall efficiency in drywall installation projects.

Quality and Consistency of Results

Pre-applied tape ensures superior quality and consistency of results by delivering uniform adhesive application across all surfaces, minimizing errors commonly found in manual taping. Manual taping relies heavily on operator skill and can lead to variable tension and uneven coverage, impacting the strength and durability of the bond. Your projects benefit from the precision and repeatability of pre-applied tape, significantly reducing defects and rework.

Labor and Skill Requirements

Pre-applied tape significantly reduces labor time by eliminating the need for manual cutting, aligning, and pressing during installation, resulting in faster project completion. Manual taping requires skilled labor to ensure precise alignment and adequate adhesion, increasing the risk of errors and rework. Efficiency gains from pre-applied tape lower overall labor costs and reduce the dependency on specialized taping expertise.

Cost Comparison and Project Budget Impact

Pre-applied tape significantly reduces labor costs by eliminating the need for manual taping, leading to faster installation times and fewer skilled workers required. Manual taping often results in higher labor expenses due to increased application time and potential for material waste. Your project budget benefits from pre-applied tape's efficiency, enabling better allocation of resources and minimizing unexpected overruns.

Durability and Long-Term Performance

Pre-applied tape offers superior durability and consistent long-term performance compared to manual taping due to factory-controlled application processes that ensure uniform adhesion and thickness. Manual taping often results in variable tape quality and uneven application, increasing the risk of tape failure and reduced lifespan under environmental stress. Enhanced durability of pre-applied tape minimizes maintenance frequency and improves overall product reliability in demanding conditions.

Common Applications and Use Cases

Pre-applied tape is commonly used in manufacturing environments where consistent, high-speed sealing is required, such as in carton packaging for e-commerce and food industries, ensuring uniform application and reducing labor costs. Manual taping is preferred in low-volume or irregular packaging scenarios like small businesses and shipping departments, where flexibility and adaptability to various box sizes and types are essential. Both methods serve crucial roles, with pre-applied tape enhancing efficiency in automated lines and manual taping providing customizable solutions for diverse packaging needs.

Choosing the Right Taping Method for Your Project

Selecting the appropriate taping method depends on your project's specific requirements, such as speed, precision, and surface type. Pre-applied tape offers consistent application and reduces labor time, making it ideal for large-scale or high-volume operations. Manual taping provides flexibility for intricate or uneven surfaces, allowing for adjustments tailored to your unique project demands.

Pre-applied tape vs manual taping Infographic

libmatt.com

libmatt.com