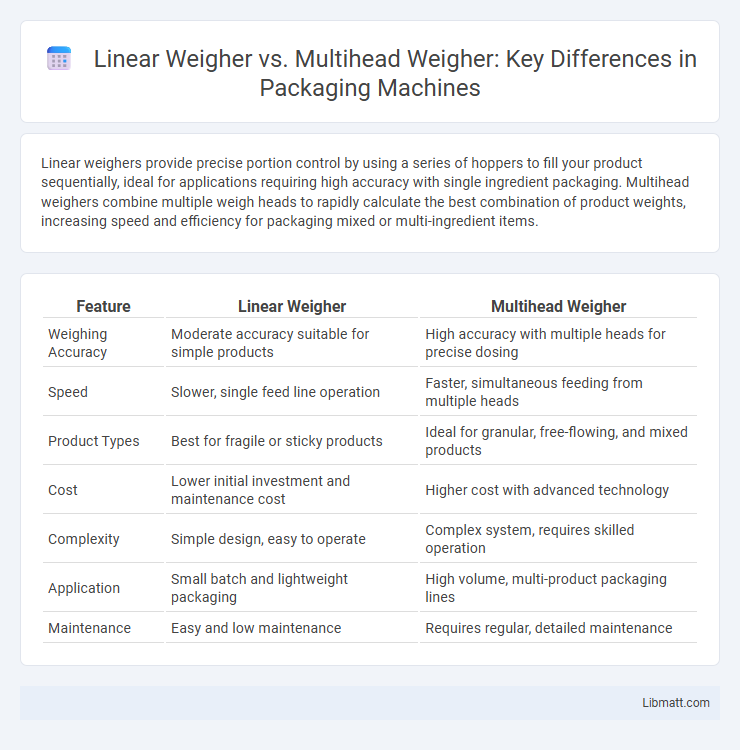

Linear weighers provide precise portion control by using a series of hoppers to fill your product sequentially, ideal for applications requiring high accuracy with single ingredient packaging. Multihead weighers combine multiple weigh heads to rapidly calculate the best combination of product weights, increasing speed and efficiency for packaging mixed or multi-ingredient items.

Table of Comparison

| Feature | Linear Weigher | Multihead Weigher |

|---|---|---|

| Weighing Accuracy | Moderate accuracy suitable for simple products | High accuracy with multiple heads for precise dosing |

| Speed | Slower, single feed line operation | Faster, simultaneous feeding from multiple heads |

| Product Types | Best for fragile or sticky products | Ideal for granular, free-flowing, and mixed products |

| Cost | Lower initial investment and maintenance cost | Higher cost with advanced technology |

| Complexity | Simple design, easy to operate | Complex system, requires skilled operation |

| Application | Small batch and lightweight packaging | High volume, multi-product packaging lines |

| Maintenance | Easy and low maintenance | Requires regular, detailed maintenance |

Introduction to Linear and Multihead Weighers

Linear weighers utilize a single or multiple horizontal feeding lanes to weigh products in a sequential manner, offering precision for simple packaging tasks with lower throughput requirements. Multihead weighers employ multiple weighing heads arranged in a circular pattern, combining individual weighment data to achieve high-speed, accurate portioning ideal for complex packaging with varied product types. This technology distinction directly impacts efficiency, accuracy, and adaptability in diverse industrial weighing and packaging applications.

How Linear Weighers Work

Linear weighers function by transferring product along a linear conveyor to a weigh hopper, where precise measurements are taken before releasing the product for packaging. Each linear weigher typically features multiple weigh hoppers aligned in a row, allowing simultaneous weighing to maintain high speed and accuracy. The system's simplicity makes it ideal for consistent products with steady flow rates, delivering reliable performance in applications requiring moderate throughput.

Working Principle of Multihead Weighers

Multihead weighers operate by dividing a product into multiple hoppers, each equipped with a weighing load cell that precisely measures small portions. These weights are rapidly combined in various permutations by a computer to achieve the target total weight with high accuracy and speed. Your choice between a linear weigher and a multihead weigher depends on the required efficiency, product nature, and required precision in packaging operations.

Key Differences Between Linear and Multihead Weighers

Linear weighers use a single dispensing lane and weigh products in a sequential manner, making them ideal for simple, low-capacity applications. Multihead weighers feature multiple weighing heads that simultaneously measure product portions, enhancing speed and accuracy for high-volume packaging processes. Your choice between the two systems depends on factors like product type, required throughput, and budget constraints.

Accuracy Comparison: Linear vs Multihead Weighers

Linear weighers provide consistent weight measurements by combining the output from multiple weigh hoppers in a sequential manner, but their accuracy can be limited by the fixed feeding speed and mechanical variations. Multihead weighers utilize multiple weighing heads operating simultaneously, offering superior accuracy by selecting the optimal combination of heads to reach the target weight with minimal deviation. Your choice between linear and multihead weighers should consider the required precision level, as multihead systems generally deliver higher accuracy in dynamic weighing applications.

Speed and Throughput Analysis

Linear weighers typically offer moderate speed with throughput ranging from 20 to 60 cycles per minute, ideal for lower volume packaging lines requiring precise single-lane dispensing. Multihead weighers excel in high-speed environments, achieving throughput rates of up to 120 cycles per minute by simultaneously weighing and combining multiple product heads, greatly enhancing efficiency for complex or bulk packaging. The choice between linear and multihead weighers depends on the required packaging speed, product type, and target production volume.

Suitability for Different Product Types

Linear weighers excel in handling products with larger, irregular shapes such as chunky snacks or fresh produce due to their precise, controlled single-chute design. Multihead weighers are more suitable for small, granular, or free-flowing products like nuts, candies, or powders because they use multiple heads to combine weights rapidly for high accuracy and speed. Product texture, fragility, and packaging requirements play a crucial role in selecting between linear and multihead weighing technology.

Cost Considerations and Investment

Linear weighers typically demand lower initial investment, making them suitable for operations with tighter budgets or simpler packaging needs. Multihead weighers, while more expensive upfront, offer higher accuracy and faster processing speeds, which can lead to cost savings through reduced product giveaway and improved efficiency over time. Your choice between these systems should balance immediate financial constraints with long-term operational gains and return on investment.

Maintenance and Operational Ease

Linear weighers require less frequent calibration and simpler mechanical upkeep, making maintenance straightforward and cost-effective. Multihead weighers involve more complex components, increasing the need for regular cleaning and precise calibration to ensure optimal performance. Your choice impacts operational ease, where linear weighers suit simpler processes, while multihead weighers demand higher technical skill but offer faster, more accurate weighing.

Choosing the Right Weighing Solution for Your Business

Choosing the right weighing solution depends on your business's production speed, product type, and accuracy requirements. Linear weighers excel in handling bulky or sticky products with moderate speed, while multihead weighers offer higher accuracy and faster output rates for granular or small items. Assess Your product characteristics and volume demands to maximize efficiency and reduce waste in your packaging process.

Linear weigher vs multihead weigher Infographic

libmatt.com

libmatt.com