Continuous inkjet technology sprays a constant stream of ink droplets, allowing high-speed printing and precise control for industrial applications, while thermal inkjet heats ink to create bubbles that propel droplets onto the paper, ideal for home and office use due to its affordability and simplicity. Your choice depends on whether you prioritize speed and durability or cost-effective, high-quality color printing.

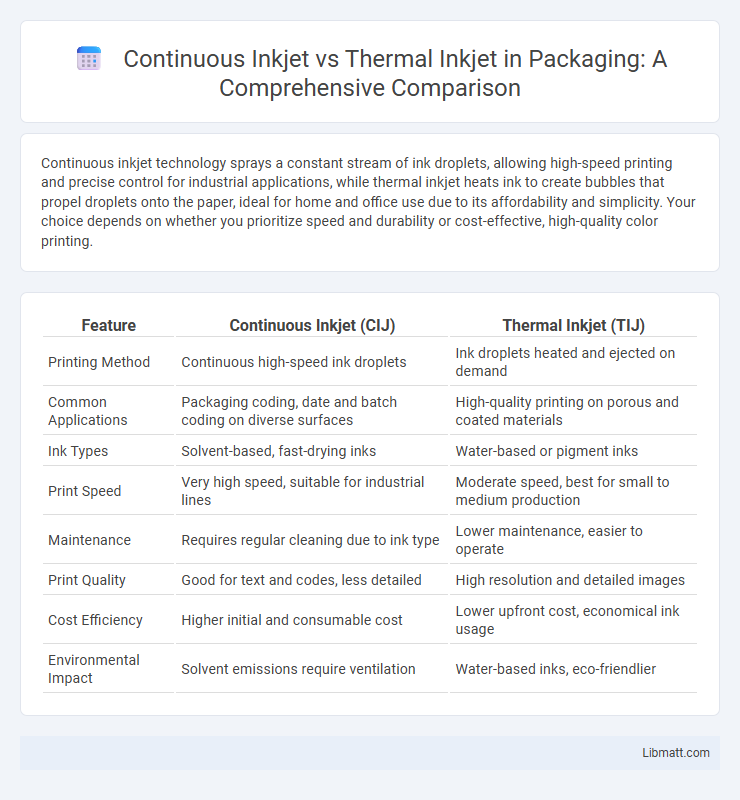

Table of Comparison

| Feature | Continuous Inkjet (CIJ) | Thermal Inkjet (TIJ) |

|---|---|---|

| Printing Method | Continuous high-speed ink droplets | Ink droplets heated and ejected on demand |

| Common Applications | Packaging coding, date and batch coding on diverse surfaces | High-quality printing on porous and coated materials |

| Ink Types | Solvent-based, fast-drying inks | Water-based or pigment inks |

| Print Speed | Very high speed, suitable for industrial lines | Moderate speed, best for small to medium production |

| Maintenance | Requires regular cleaning due to ink type | Lower maintenance, easier to operate |

| Print Quality | Good for text and codes, less detailed | High resolution and detailed images |

| Cost Efficiency | Higher initial and consumable cost | Lower upfront cost, economical ink usage |

| Environmental Impact | Solvent emissions require ventilation | Water-based inks, eco-friendlier |

Introduction to Inkjet Printing Technologies

Continuous inkjet (CIJ) technology propels a constant stream of ink droplets, selectively deflecting them to form images, ideal for high-speed industrial coding. Thermal inkjet (TIJ) relies on heating elements to vaporize ink and generate droplets on demand, commonly used in desktop and office printers due to precise, controlled droplet placement. Both technologies differ in mechanism, application, and maintenance, making CIJ suitable for non-contact, high-speed marking and TIJ preferable for detailed, low-volume printing tasks.

What is Continuous Inkjet (CIJ)?

Continuous Inkjet (CIJ) technology propels a continuous stream of ink droplets at high frequency toward a substrate, with unused droplets being recirculated and reused to minimize waste. This method is ideal for high-speed industrial applications requiring precise, non-contact printing on diverse surfaces such as metals, plastics, and glass. CIJ systems offer durable, high-resolution codes and markings that are resistant to smudging, making them suitable for product identification and traceability in manufacturing environments.

What is Thermal Inkjet (TIJ)?

Thermal Inkjet (TIJ) technology uses heat to create a bubble that propels ink droplets onto the paper for precise and high-resolution printing. TIJ printers are widely utilized in consumer and office environments due to their efficiency, lower maintenance, and ability to produce sharp text and vibrant images. Compared to Continuous Inkjet (CIJ), TIJ offers cleaner operation with less ink waste, making it ideal for detailed printing tasks.

Key Differences Between CIJ and TIJ

Continuous Inkjet (CIJ) technology propels ink droplets continuously through a nozzle, allowing precise, high-speed printing ideal for industrial applications, while Thermal Inkjet (TIJ) uses heat to create bubbles that force ink onto the substrate, ensuring high-resolution imaging suitable for office and home printers. CIJ systems require complex maintenance and solvent-based inks for durability on various surfaces, whereas TIJ printers operate with maintenance-friendly, water-based inks limited to porous materials. CIJ offers superior speed and versatility for coding on products like packaging and bottles, while TIJ excels in quality and cost-effectiveness for everyday printing tasks.

Print Quality Comparison: CIJ vs TIJ

Continuous inkjet (CIJ) printers offer high-speed printing with fine droplets, resulting in consistent print quality suited for industrial applications. Thermal inkjet (TIJ) printers provide sharper, more precise images with vibrant colors, making them ideal for detailed graphics and high-resolution prints. Your choice depends on whether you prioritize durability and speed (CIJ) or image clarity and color accuracy (TIJ).

Ink Type and Compatibility

Continuous inkjet printers use solvent-based or oil-based inks compatible with various materials like plastics and metals, enabling durable, industrial-quality markings. Thermal inkjet printers utilize water-based dye or pigment inks designed primarily for paper and standard office media, providing high-resolution prints with vivid colors. Your choice depends on the substrate and ink compatibility required for your specific printing application.

Maintenance and Operation Costs

Continuous inkjet printers generally have higher maintenance and operation costs due to complex printhead technology requiring frequent cleaning and specialized parts. Thermal inkjet printers offer lower upkeep expenses with simpler mechanisms and inexpensive replaceable cartridges, making them more cost-effective for small to medium-volume printing. Your choice should consider these factors alongside usage frequency to optimize total cost of ownership.

Industrial Applications of CIJ and TIJ

Continuous inkjet (CIJ) technology is widely used in industrial applications requiring high-speed, non-contact printing on diverse substrates such as plastics, metals, and glass, with capabilities for coding and marking in packaging, electronics, and automotive sectors. Thermal inkjet (TIJ) excels in high-resolution printing on porous materials like paper and cardboard, making it ideal for packaging and product labeling where image quality and precision are critical. CIJ systems offer greater durability and solvent-based inks suitable for harsh environments, whereas TIJ systems provide cost-effective, clean operation favored in food and pharmaceutical industries.

Advantages and Disadvantages of Each Technology

Continuous inkjet (CIJ) technology offers high-speed printing with the ability to print on various substrates, making it ideal for industrial applications, but it requires complex maintenance and uses solvent-based inks that can be costly and hazardous. Thermal inkjet (TIJ) technology provides precise, high-resolution prints with lower operational costs and simpler maintenance, suitable for office and home use, yet it struggles with fast-drying inks and is limited to specific ink types. CIJ excels in durability and versatility for large-scale usage, while TIJ prioritizes print quality and user convenience in smaller-scale environments.

Choosing the Right Inkjet Technology for Your Needs

Selecting the right inkjet technology depends on your printing application and requirements for speed, print quality, and cost-efficiency. Continuous inkjet (CIJ) excels in high-speed industrial printing with fast-drying, solvent-based inks ideal for coding and marking on various surfaces. Thermal inkjet (TIJ) offers high-resolution output suited for detailed graphics or text on porous materials, using heat to eject water-based inks with minimal maintenance.

Continuous inkjet vs thermal inkjet Infographic

libmatt.com

libmatt.com