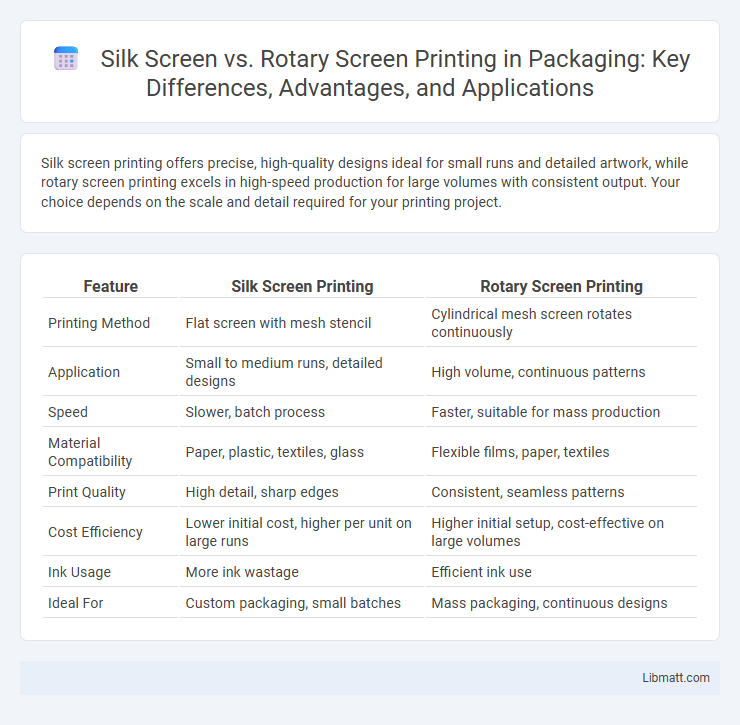

Silk screen printing offers precise, high-quality designs ideal for small runs and detailed artwork, while rotary screen printing excels in high-speed production for large volumes with consistent output. Your choice depends on the scale and detail required for your printing project.

Table of Comparison

| Feature | Silk Screen Printing | Rotary Screen Printing |

|---|---|---|

| Printing Method | Flat screen with mesh stencil | Cylindrical mesh screen rotates continuously |

| Application | Small to medium runs, detailed designs | High volume, continuous patterns |

| Speed | Slower, batch process | Faster, suitable for mass production |

| Material Compatibility | Paper, plastic, textiles, glass | Flexible films, paper, textiles |

| Print Quality | High detail, sharp edges | Consistent, seamless patterns |

| Cost Efficiency | Lower initial cost, higher per unit on large runs | Higher initial setup, cost-effective on large volumes |

| Ink Usage | More ink wastage | Efficient ink use |

| Ideal For | Custom packaging, small batches | Mass packaging, continuous designs |

Introduction to Silk Screen and Rotary Screen Printing

Silk screen printing uses a flat mesh screen to transfer ink onto fabric, allowing for detailed designs and vibrant colors, ideal for small to medium runs. Rotary screen printing employs cylindrical screens that rotate continuously, enabling high-speed production and consistent prints suitable for large-scale textile manufacturing. Both methods offer unique advantages in print quality, production efficiency, and cost-effectiveness depending on project requirements.

Core Differences Between Silk Screen and Rotary Screen Printing

Silk screen printing uses a flat mesh screen where ink is manually pushed through open areas, ideal for short runs and intricate designs with vibrant colors. Rotary screen printing employs cylindrical screens that rotate, enabling faster, continuous printing suitable for high-volume production on fabrics like textiles. Your choice depends on production scale and design complexity, with silk screen favoring detailed artwork and rotary screen excelling in speed and efficiency.

How Silk Screen Printing Works

Silk screen printing works by forcing ink through a fine mesh stencil onto the printing surface, creating vibrant, durable designs ideal for textiles, posters, and promotional items. The screen is coated with a light-sensitive emulsion, exposed to a design, and then washed out to create a precise stencil that blocks ink in non-image areas. This method ensures sharp, high-quality prints with excellent color opacity, making it a preferred choice for your custom apparel and branding projects.

How Rotary Screen Printing Works

Rotary screen printing uses cylindrical screens that rotate continuously, allowing ink to be applied evenly across fabric or other materials at high speeds. This method enables precise, consistent patterns ideal for large-scale production runs, as the screen's mesh controls ink flow through tiny openings onto the substrate. Your designs benefit from increased efficiency and sharp detail with minimal downtime compared to traditional flat silk screen printing.

Material Suitability for Each Printing Method

Silk screen printing is ideal for flat surfaces and works best with thicker inks on materials like cotton, polyester, and blends, providing vibrant and durable prints. Rotary screen printing excels in high-volume production on continuous fabrics such as knits, wovens, and technical textiles, offering speed and consistency for smooth, lightweight materials. Understanding your material's texture and production scale helps determine the most suitable printing method for optimal results.

Production Speed and Efficiency Comparison

Rotary screen printing offers significantly higher production speeds, reaching up to 1000 meters per hour, compared to traditional silk screen printing, which typically runs at 50-150 meters per hour. The continuous rotary process reduces downtime and waste, making it more efficient for large-volume textile and packaging projects. Silk screen printing provides greater color density and detail but is less suited for rapid, mass-production environments.

Cost Analysis: Silk Screen vs Rotary Screen Printing

Silk screen printing typically incurs higher setup costs due to labor-intensive stencil preparation and slower production speeds, making it less cost-effective for large-volume runs. Rotary screen printing, with automated continuous screens, offers lower per-unit costs and faster output, making it ideal for high-volume textile printing projects. Your choice between silk screen and rotary screen printing should consider production volume and budget constraints to optimize cost efficiency.

Print Quality and Design Capabilities

Silk screen printing offers high print quality with sharp, vibrant colors and excellent detail, making it ideal for intricate designs and small batches. Rotary screen printing excels in producing consistent prints on large volumes with smooth gradients and fine color transitions, suitable for seamless patterns and continuous designs. Your choice depends on whether you prioritize detailed, high-quality prints or efficient, large-scale production with versatile design capabilities.

Common Applications of Each Printing Technique

Silk screen printing is widely used for producing vibrant, high-quality designs on garments, posters, and promotional materials, making it ideal for small- to medium-sized runs with detailed color work. Rotary screen printing excels in high-volume textile production, particularly for apparel, home furnishings, and wallpaper, offering fast printing speeds and continuous patterns on fabric rolls. Each technique serves distinct market needs, with silk screen preferred for customization and rotary screen dominating mass production.

Choosing the Right Printing Method for Your Needs

Silk screen printing offers exceptional detail and vibrant colors, ideal for short runs and intricate designs on various materials. Rotary screen printing excels in high-volume production, providing continuous printing with faster output and lower unit costs. Evaluating your project's size, design complexity, and budget will help you determine whether silk screen or rotary screen printing is the perfect fit for your needs.

Silk screen vs rotary screen printing Infographic

libmatt.com

libmatt.com