HD flexo offers higher resolution and sharper image quality compared to conventional flexo, enhancing print detail and color vibrancy. Your packaging or labels will benefit from improved consistency and faster turnaround times due to advanced plate-making and printing technology.

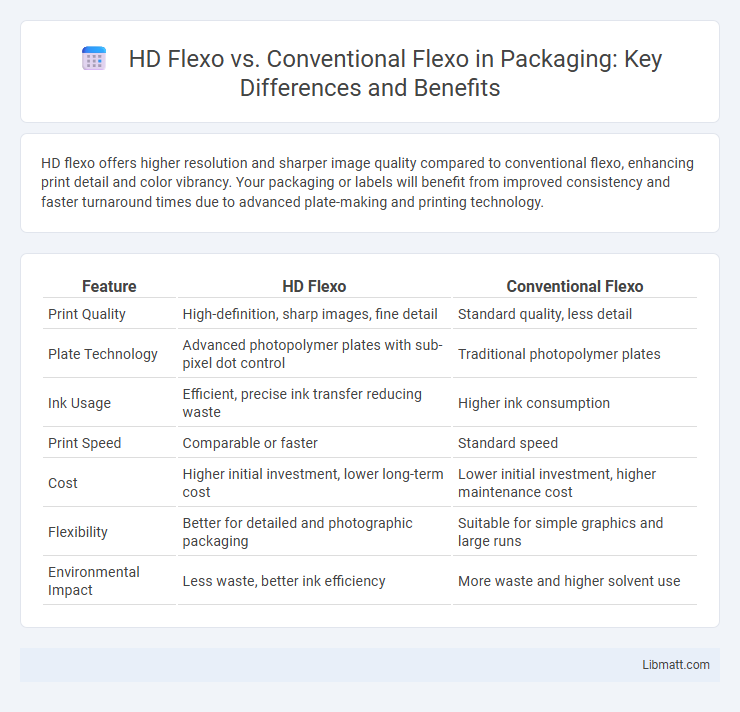

Table of Comparison

| Feature | HD Flexo | Conventional Flexo |

|---|---|---|

| Print Quality | High-definition, sharp images, fine detail | Standard quality, less detail |

| Plate Technology | Advanced photopolymer plates with sub-pixel dot control | Traditional photopolymer plates |

| Ink Usage | Efficient, precise ink transfer reducing waste | Higher ink consumption |

| Print Speed | Comparable or faster | Standard speed |

| Cost | Higher initial investment, lower long-term cost | Lower initial investment, higher maintenance cost |

| Flexibility | Better for detailed and photographic packaging | Suitable for simple graphics and large runs |

| Environmental Impact | Less waste, better ink efficiency | More waste and higher solvent use |

Introduction to Flexographic Printing

Flexographic printing utilizes flexible relief plates to transfer ink onto various substrates, with HD Flexo offering higher resolution and sharper image quality compared to conventional flexo. HD Flexo employs advanced digital screening and precise dot placement, enabling finer details and smoother gradients for packaging and labels. Conventional flexo, while cost-effective for large runs, generally produces lower resolution and less vibrant prints, making HD Flexo the preferred choice for premium print quality.

What is Conventional Flexo Printing?

Conventional flexo printing uses rubber or photopolymer plates with lower resolution to transfer ink onto various substrates, producing less detailed images compared to HD flexo. It relies on aniline dyes or conventional inks, resulting in broader halftones and less precise color reproduction. Your packaging or label might show more visible screening and softer image quality under conventional flexo methods.

Understanding HD Flexo Technology

HD Flexo technology utilizes advanced plate-making techniques and high-resolution printing components to deliver sharper images and finer detail compared to conventional flexo. Your prints benefit from enhanced color vibrancy and consistent quality, thanks to improved ink transfer and precise dot reproduction. This innovation streamlines production efficiency while maintaining cost-effectiveness in packaging and label printing applications.

Key Differences Between HD Flexo and Conventional Flexo

HD flexo offers superior image resolution with finer dots and smoother gradients compared to conventional flexo, resulting in sharper and more detailed prints. The advanced photopolymer plates used in HD flexo provide better ink control and reduced dot gain, enhancing overall print quality. You will notice increased consistency and vibrancy in packaging and label production when choosing HD flexo over conventional flexo methods.

Print Quality Comparison

HD flexo printing delivers significantly higher resolution and sharper image detail compared to conventional flexo, utilizing advanced screening technology that achieves finer dot structures and smoother gradients. This enhanced print quality results in more accurate color reproduction and improved consistency, especially on challenging substrates. Conventional flexo, while cost-effective, often produces lower definition prints with less precise color transitions and visible halftone dot patterns.

Efficiency and Workflow Advancements

HD flexo offers significantly higher efficiency compared to conventional flexo by utilizing advanced digital plate-making technology that reduces setup times and minimizes waste. Your workflow benefits from faster job changes and improved print consistency, leading to increased productivity and cost savings. Enhanced precision in HD flexo accelerates quality control processes, streamlining operations across the entire print production cycle.

Cost Implications: HD Flexo vs Conventional Flexo

HD Flexo printing typically involves higher initial costs due to advanced imaging technology and finer screen rulings that increase plate production expenses. Conventional Flexo remains more cost-effective for short runs and less complex designs because of simpler plate making and lower equipment investment. Over time, HD Flexo can reduce waste and improve print quality, offering better value in high-volume, detail-oriented applications despite higher upfront costs.

Environmental Impact and Sustainability

HD flexo printing significantly reduces environmental impact by using less ink and generating minimal waste compared to conventional flexo. Its advanced ink transfer technology lowers VOC emissions and conserves resources, promoting greater sustainability. You can achieve eco-friendly production goals while maintaining high-quality print output with HD flexo.

Industry Applications and Use Cases

HD flexo technology offers superior print quality and finer details, making it ideal for packaging in the food, beverage, and pharmaceutical industries where high-resolution images and accurate color reproduction are critical. Conventional flexo remains widely used for labels, corrugated cartons, and newspapers due to its cost-effectiveness and faster setup times. Your choice between HD flexo and conventional flexo depends on the specific industry requirements for print precision, production speed, and budget constraints.

Choosing the Right Flexo Printing Solution

HD flexo printing delivers higher resolution and finer detail compared to conventional flexo, making it ideal for premium packaging requiring sharp images and vibrant colors. Conventional flexo remains cost-effective for large runs with simpler designs, offering reliable quality with faster setup times. Businesses must evaluate production volume, image quality demands, and budget constraints to choose the right flexo printing solution.

HD flexo vs conventional flexo Infographic

libmatt.com

libmatt.com