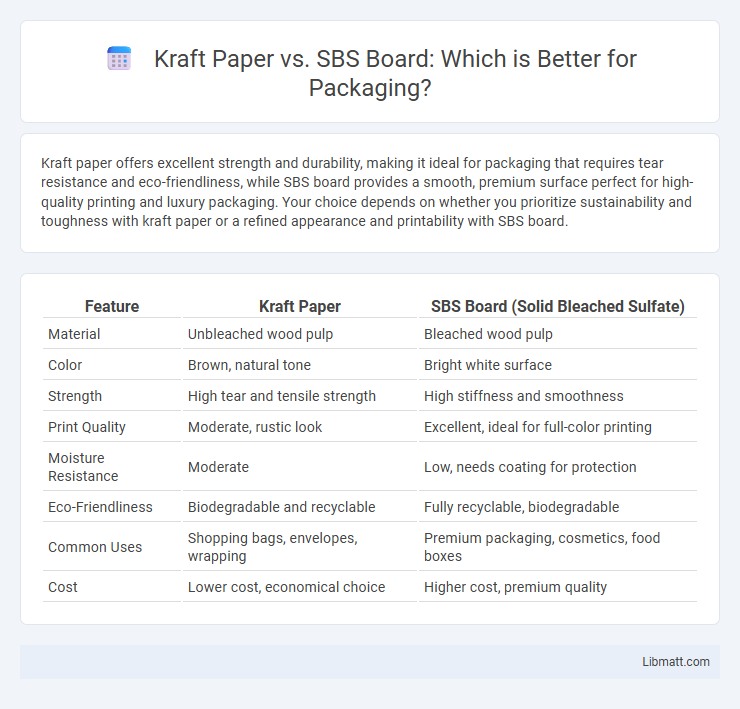

Kraft paper offers excellent strength and durability, making it ideal for packaging that requires tear resistance and eco-friendliness, while SBS board provides a smooth, premium surface perfect for high-quality printing and luxury packaging. Your choice depends on whether you prioritize sustainability and toughness with kraft paper or a refined appearance and printability with SBS board.

Table of Comparison

| Feature | Kraft Paper | SBS Board (Solid Bleached Sulfate) |

|---|---|---|

| Material | Unbleached wood pulp | Bleached wood pulp |

| Color | Brown, natural tone | Bright white surface |

| Strength | High tear and tensile strength | High stiffness and smoothness |

| Print Quality | Moderate, rustic look | Excellent, ideal for full-color printing |

| Moisture Resistance | Moderate | Low, needs coating for protection |

| Eco-Friendliness | Biodegradable and recyclable | Fully recyclable, biodegradable |

| Common Uses | Shopping bags, envelopes, wrapping | Premium packaging, cosmetics, food boxes |

| Cost | Lower cost, economical choice | Higher cost, premium quality |

Introduction to Kraft Paper and SBS Board

Kraft paper is a durable, unbleached paper material primarily used for packaging, known for its high tear resistance and eco-friendly properties due to its natural wood pulp composition. SBS (Solid Bleached Sulfate) board is a premium, white, coated paperboard favored in luxury packaging and printing because of its smooth surface and superior printability. Understanding the differences between Kraft paper and SBS board helps you choose the right material for sustainable packaging solutions and high-quality visual presentation.

Composition and Manufacturing Process

Kraft paper is made from wood pulp through the kraft process, involving chemical treatment that removes lignin and strengthens fibers, resulting in durable, recyclable paper. SBS (Solid Bleached Sulfate) board is composed of bleached virgin wood fibers produced via a sulfate pulping method, with a smooth, bright white surface ideal for premium packaging. Understanding the composition and manufacturing differences helps you select the right material for strength, appearance, and sustainability needs.

Physical Properties Comparison

Kraft paper exhibits high tensile strength and excellent tear resistance due to its long fiber cellulose content, making it ideal for packaging requiring durability and flexibility. SBS (Solid Bleached Sulfate) board offers superior smoothness, brightness, and stiffness because it is made from bleached virgin fibers, enhancing print quality and structural integrity. Your choice depends on whether you prioritize the robust physical durability of Kraft paper or the refined surface and rigidity of SBS board for specific packaging or printing needs.

Strength and Durability

Kraft paper is known for its high tensile strength and excellent tear resistance due to its long fibers and minimal processing, making it ideal for packaging requiring flexibility and durability. SBS (Solid Bleached Sulfate) board offers superior stiffness and surface smoothness, providing greater crush resistance and durability for premium packaging applications. While Kraft paper excels in strength for heavy-duty uses, SBS board delivers enhanced rigidity and durability for protective and high-quality display packaging.

Printability and Surface Finish

Kraft paper offers a natural, coarse surface that provides excellent ink absorption, making it ideal for rustic or eco-friendly packaging designs with a matte finish. SBS board features a smooth, high-quality surface with superior printability, producing sharp graphics and vibrant colors ideal for premium retail packaging. Choosing between them depends on your need for either a textured, organic look or a polished, professional appearance.

Environmental Impact and Sustainability

Kraft paper is highly sustainable due to its production from natural wood fibers using a chemical pulping process that results in strong, biodegradable, and recyclable material with low environmental footprint. SBS (Solid Bleached Sulfate) board, while also recyclable and widely used in packaging for its smooth, white surface, requires more intensive bleaching and chemical treatments, leading to higher energy consumption and environmental impact. Your choice between kraft paper and SBS board should consider the balance between eco-friendliness and packaging quality, with kraft paper typically offering superior sustainability benefits.

Cost Analysis: Kraft Paper vs SBS Board

Kraft paper offers a cost-effective packaging solution due to its lower production expenses and availability from recycled materials, making it ideal for budget-sensitive projects. SBS board, or Solid Bleached Sulfate board, carries higher manufacturing costs attributed to its premium virgin pulp content and superior whiteness, resulting in a more expensive but aesthetically appealing option. The choice between Kraft paper and SBS board hinges on balancing cost constraints against the desired packaging quality and visual impact.

Common Applications in Packaging

Kraft paper is widely used for packaging applications requiring durability and tear resistance, such as wrapping heavy goods, making paper bags, and protective cushioning. SBS (solid bleached sulfate) board is favored in high-end packaging for consumer products like cosmetics, pharmaceuticals, and food items due to its smooth surface, printability, and moisture resistance. Both materials serve distinct purposes, with kraft paper excelling in industrial and protective packaging and SBS board preferred for premium retail packaging.

Market Trends and Consumer Preferences

Kraft paper continues to gain popularity in sustainable packaging markets due to its eco-friendly properties and biodegradability, meeting increasing consumer demand for environmentally responsible products. SBS (Solid Bleached Sulfate) board remains preferred for premium packaging requiring high print quality and a smooth, white surface, appealing to brands targeting luxury and cosmetics sectors. Your choice between Kraft paper and SBS board should align with current market trends emphasizing sustainability and product presentation to capture consumer preferences effectively.

Choosing the Right Material for Your Needs

Kraft paper offers durability and eco-friendliness, making it ideal for packaging that requires strength and recyclability, while SBS board provides a smooth, high-quality surface perfect for printing and premium packaging applications. Choosing between kraft paper and SBS board depends on the product's protection needs, aesthetic appeal, and environmental considerations. For heavy-duty shipping, kraft paper excels, whereas SBS board suits retail packaging that demands visual impact and surface finish.

Kraft paper vs SBS board Infographic

libmatt.com

libmatt.com