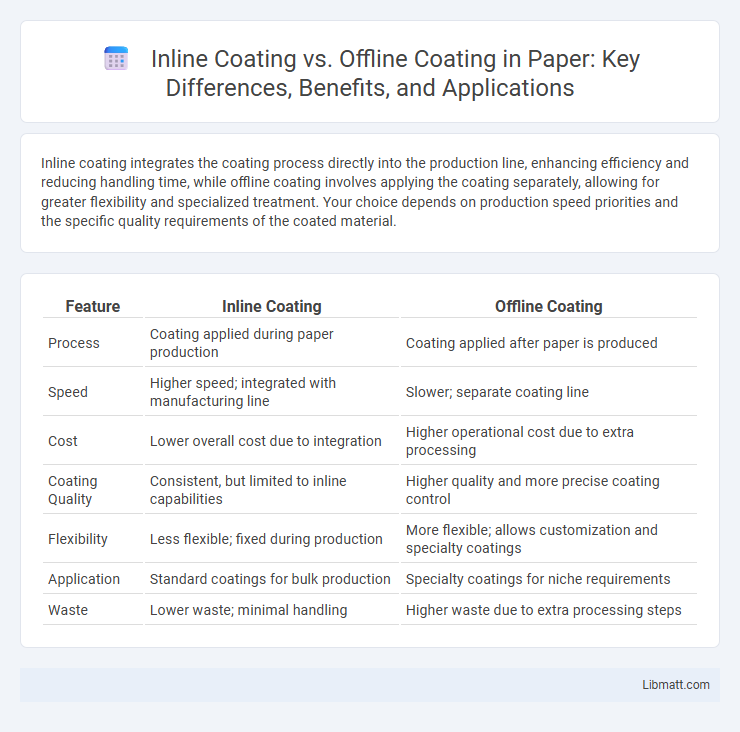

Inline coating integrates the coating process directly into the production line, enhancing efficiency and reducing handling time, while offline coating involves applying the coating separately, allowing for greater flexibility and specialized treatment. Your choice depends on production speed priorities and the specific quality requirements of the coated material.

Table of Comparison

| Feature | Inline Coating | Offline Coating |

|---|---|---|

| Process | Coating applied during paper production | Coating applied after paper is produced |

| Speed | Higher speed; integrated with manufacturing line | Slower; separate coating line |

| Cost | Lower overall cost due to integration | Higher operational cost due to extra processing |

| Coating Quality | Consistent, but limited to inline capabilities | Higher quality and more precise coating control |

| Flexibility | Less flexible; fixed during production | More flexible; allows customization and specialty coatings |

| Application | Standard coatings for bulk production | Specialty coatings for niche requirements |

| Waste | Lower waste; minimal handling | Higher waste due to extra processing steps |

Introduction to Inline and Offline Coating

Inline coating integrates the coating process directly into the production line, enhancing efficiency by applying coatings immediately after web formation or printing. Offline coating occurs separately from the main production line, allowing for greater flexibility in coating techniques and customized finishes but often involves additional handling and time. Your choice between inline and offline coating depends on production speed requirements, coating precision, and operational workflow.

Definition of Inline Coating

Inline coating refers to the process where coatings are applied directly during the manufacturing or production line, integrating coating steps with other processing stages to enhance efficiency and reduce handling time. This method allows for continuous application of coatings on materials such as paper, film, or metal substrates immediately after forming or printing. Inline coating improves adhesion, consistency, and productivity by synchronizing coating application with upstream and downstream operations in a single production setup.

Understanding Offline Coating

Offline coating involves applying a protective or decorative layer to materials after the initial production process, allowing for greater customization and quality control. This method enables precise adjustments to coating thickness, texture, and color without interrupting the main manufacturing line. Your choice of offline coating can enhance product durability and aesthetic appeal, ensuring superior performance tailored to specific industry requirements.

Key Differences Between Inline and Offline Coating

Inline coating integrates the coating process directly into the production line, enabling real-time application and immediate quality control, which boosts efficiency and reduces handling errors. Offline coating is performed separately from the main production process, allowing more precise control over coating parameters and the use of specialized equipment for complex finishes. Key differences include process integration, speed, quality control flexibility, and equipment complexity, impacting overall production cost and turnaround time.

Advantages of Inline Coating

Inline coating integrates the coating process directly within the production line, significantly reducing production time and operational costs. This method enhances product consistency by minimizing material handling and exposure to contaminants, leading to higher quality finishes. Furthermore, inline coating allows for real-time process adjustments, improving efficiency and reducing waste in manufacturing.

Benefits of Offline Coating

Offline coating offers enhanced flexibility and precision by allowing for specialized coating applications after the primary manufacturing process, reducing downtime on main production lines. It enables the use of a broader range of coating materials and techniques, improving product customization and performance. This method also facilitates thorough quality control and testing, ensuring higher consistency and reduced defects in the final product.

Challenges of Inline Coating

Inline coating presents challenges such as maintaining consistent coating thickness at high production speeds, which can lead to uneven application and product defects. Equipment calibration must be precise to avoid downtime and ensure quality control, complicating integration with existing manufacturing lines. Additionally, inline systems face difficulty managing drying times and substrate variability, impacting overall process efficiency.

Limitations of Offline Coating

Offline coating faces significant limitations such as increased production costs and longer lead times due to separate processing steps after primary manufacturing. It lacks real-time quality control, leading to higher risks of coating defects and inconsistent finishes. The need for additional equipment and handling also heightens the possibility of contamination and damage to substrates during transport between processes.

Application Areas: Inline vs Offline Coating

Inline coating is predominantly used in high-speed manufacturing environments such as flexible packaging, labels, and paper products, where continuous production and immediate coating application enhance efficiency and reduce handling errors. Offline coating is preferred in specialized applications requiring complex, multi-layer coatings or precise surface treatments, commonly found in automotive parts, electronics, and specialty films, allowing for greater process control and customization. Industries prioritize inline coating for streamlined, volume-driven processes, whereas offline coating is selected when quality and flexibility in coating properties are critical.

Choosing the Right Coating Process

Selecting the appropriate coating process depends on production speed, quality requirements, and equipment compatibility; inline coating integrates directly into the production line for faster throughput and consistent application, while offline coating provides greater flexibility and precision for specialized finishes. Inline coating is ideal for high-volume manufacturing with minimal downtime, ensuring seamless integration and cost efficiency. Offline coating suits smaller batches or complex coatings where meticulous control and post-processing are essential for achieving superior product performance.

Inline coating vs offline coating Infographic

libmatt.com

libmatt.com