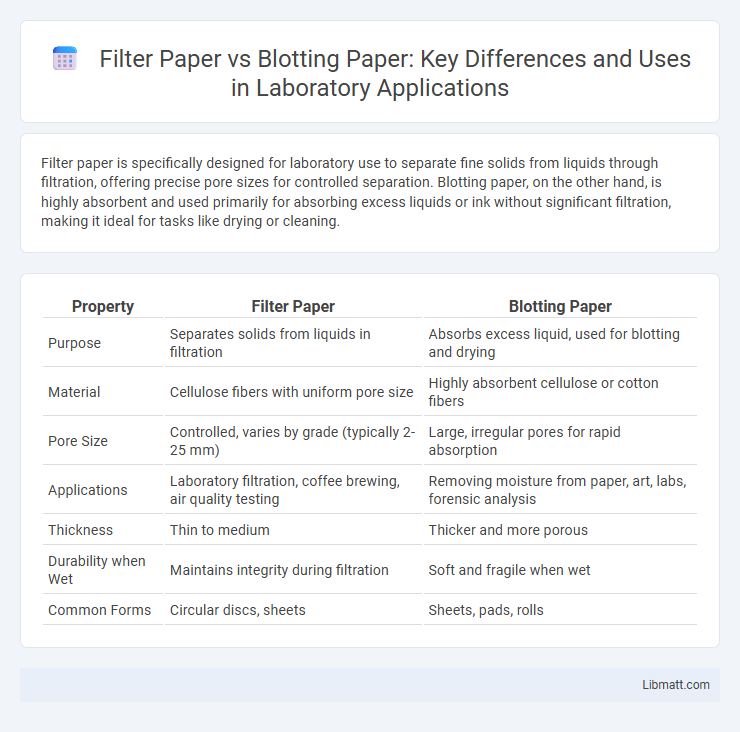

Filter paper is specifically designed for laboratory use to separate fine solids from liquids through filtration, offering precise pore sizes for controlled separation. Blotting paper, on the other hand, is highly absorbent and used primarily for absorbing excess liquids or ink without significant filtration, making it ideal for tasks like drying or cleaning.

Table of Comparison

| Property | Filter Paper | Blotting Paper |

|---|---|---|

| Purpose | Separates solids from liquids in filtration | Absorbs excess liquid, used for blotting and drying |

| Material | Cellulose fibers with uniform pore size | Highly absorbent cellulose or cotton fibers |

| Pore Size | Controlled, varies by grade (typically 2-25 mm) | Large, irregular pores for rapid absorption |

| Applications | Laboratory filtration, coffee brewing, air quality testing | Removing moisture from paper, art, labs, forensic analysis |

| Thickness | Thin to medium | Thicker and more porous |

| Durability when Wet | Maintains integrity during filtration | Soft and fragile when wet |

| Common Forms | Circular discs, sheets | Sheets, pads, rolls |

Introduction to Filter Paper and Blotting Paper

Filter paper and blotting paper are both specialized types of absorbent paper used in scientific and artistic applications. Filter paper, typically made from cellulose fibers, is designed to separate fine solids from liquids during filtration, ensuring clarity in laboratory experiments, while blotting paper is engineered to absorb excess liquids, such as ink or moisture, without spreading. Your choice between these papers depends on whether you need precise filtration or rapid absorption for tasks like chromatography or drying.

Defining Filter Paper

Filter paper is a highly porous, cellulose-based material specifically designed for separating fine solids from liquids or gases during filtration processes in laboratories. Its uniform pore size allows for consistent particle retention, making it ideal for analytical, qualitative, and quantitative applications. You can distinguish filter paper from blotting paper by its primary function in filtration and its controlled permeability.

Defining Blotting Paper

Blotting paper is highly absorbent paper designed to quickly soak up excess liquids, such as ink or oils, without spreading or smudging. Unlike filter paper, which traps solid particles during filtration, blotting paper is primarily used for drying and absorbing purposes in laboratories and art applications. Its porous structure enables rapid liquid absorption, making it essential for blotting processes where precision and speed are critical.

Key Material Differences

Filter paper is made from cellulose fibers designed for precise filtration, featuring uniform pore sizes to separate solids from liquids effectively. Blotting paper, also cellulose-based, is highly absorbent with a coarser texture, optimized to soak up liquids rather than filter them. Understanding these key material differences helps you select the right paper for tasks involving liquid absorption or particle filtration.

Manufacturing Processes Compared

Filter paper is manufactured through controlled, uniform pulping followed by precision refining and calendaring to create consistent porosity for effective filtration. Blotting paper production emphasizes soft, highly absorbent fibers and often undergoes less pressing to maintain thick, porous texture for rapid liquid absorption. Your choice depends on whether precise filtration or fast absorption suits your application best.

Primary Uses of Filter Paper

Filter paper is primarily used in laboratory settings for separating fine particles from liquids through filtration processes, crucial in chemical analysis, microbiology, and environmental testing. It effectively isolates precipitates during titrations, clarifies solutions, and supports vacuum filtration. Its porous structure and varying pore sizes make it ideal for capturing solids while allowing liquids to pass, distinguishing it from blotting paper's absorption-focused applications.

Primary Uses of Blotting Paper

Blotting paper is primarily used to absorb excess ink or oil from surfaces such as writing paper or skin, making it essential in art, calligraphy, and cosmetic applications. Unlike filter paper, which is designed for separating fine particles from liquids in laboratory filtration processes, blotting paper features a highly absorbent, coarse texture tailored for quick moisture absorption. Your ability to keep ink smudges and oily residues under control depends on the unique properties of blotting paper in contrast to the more specialized filtering function of filter paper.

Filtration vs Absorption: Functional Contrasts

Filter paper is specifically designed for filtration, allowing liquids to pass while trapping solid particles, making it essential in laboratory and industrial applications. Blotting paper primarily serves absorption purposes, quickly soaking up excess liquids like ink or moisture without filtering solids. Your choice between the two depends on whether you need to separate substances by filtration or simply absorb and remove liquids.

Advantages and Limitations of Each Paper Type

Filter paper excels in precise particle retention and chemical compatibility, making it ideal for laboratory filtration and analytical applications, but it may clog easily with dense suspensions and lacks absorbency for large spills. Blotting paper offers superior absorbency and moisture control, effectively managing ink and liquid spills while being less suitable for fine particulate filtration due to its porous, less uniform structure. The choice depends on the specific task requirements: filter paper for accurate separation and chemical analysis, blotting paper for rapid liquid absorption and surface drying.

Choosing the Right Paper: Practical Guidelines

Filter paper is designed for precise particle retention during filtration, making it ideal for laboratory applications requiring clear liquid separation, while blotting paper excels at absorbing excess moisture or ink in art and medical settings. Selecting the appropriate paper depends on the task: use filter paper for chemical analysis, environmental testing, or microbiology, and choose blotting paper for drying, oil absorption, or ink blotting. Consider factors such as absorption rate, particle retention size, thickness, and porosity to ensure optimal performance for your specific application.

filter paper vs blotting paper Infographic

libmatt.com

libmatt.com