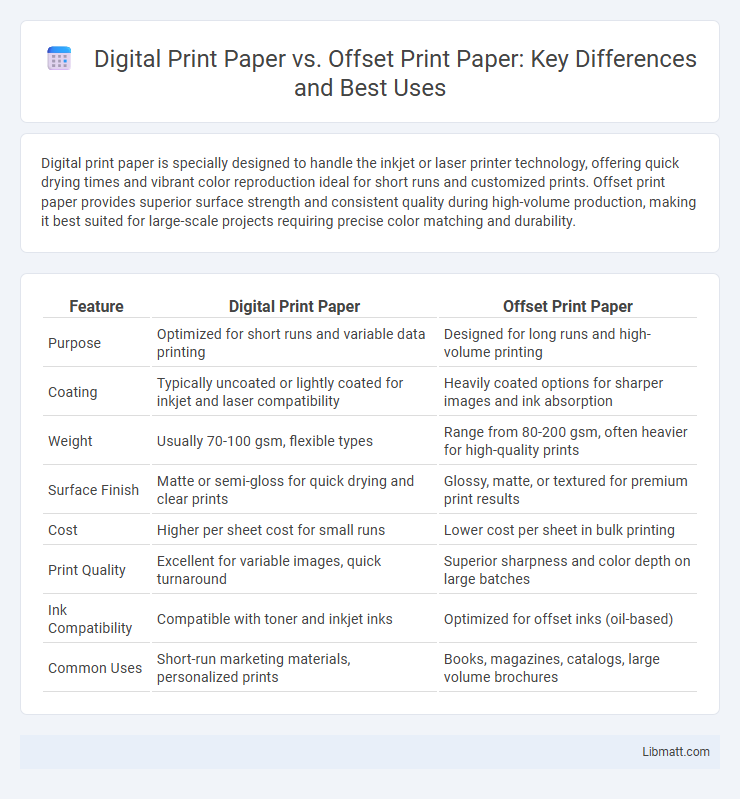

Digital print paper is specially designed to handle the inkjet or laser printer technology, offering quick drying times and vibrant color reproduction ideal for short runs and customized prints. Offset print paper provides superior surface strength and consistent quality during high-volume production, making it best suited for large-scale projects requiring precise color matching and durability.

Table of Comparison

| Feature | Digital Print Paper | Offset Print Paper |

|---|---|---|

| Purpose | Optimized for short runs and variable data printing | Designed for long runs and high-volume printing |

| Coating | Typically uncoated or lightly coated for inkjet and laser compatibility | Heavily coated options for sharper images and ink absorption |

| Weight | Usually 70-100 gsm, flexible types | Range from 80-200 gsm, often heavier for high-quality prints |

| Surface Finish | Matte or semi-gloss for quick drying and clear prints | Glossy, matte, or textured for premium print results |

| Cost | Higher per sheet cost for small runs | Lower cost per sheet in bulk printing |

| Print Quality | Excellent for variable images, quick turnaround | Superior sharpness and color depth on large batches |

| Ink Compatibility | Compatible with toner and inkjet inks | Optimized for offset inks (oil-based) |

| Common Uses | Short-run marketing materials, personalized prints | Books, magazines, catalogs, large volume brochures |

Introduction to Digital and Offset Print Papers

Digital print paper is engineered to withstand high heat and toner adhesion, offering smooth texture and consistent brightness optimal for laser and inkjet printers. Offset print paper is designed to absorb oil-based inks efficiently, providing superior ink holdout and durability suitable for high-volume printing presses. Both papers vary in weight, finish, and brightness, catering to different printing technologies and quality requirements.

Key Differences Between Digital and Offset Printing

Digital print paper is specially designed for short-run printing processes using toner or inkjet technology, offering quick turnaround and high-quality images on thinner, coated substrates. Offset print paper, however, suits long-run production with its durability and compatibility with oil-based inks, often thicker and uncoated to handle the heat and pressure of traditional offset presses. Your choice should consider the print volume, budget, and desired finish, as digital excels in flexibility and customization, while offset provides consistent color accuracy and cost-efficiency for large batches.

Paper Composition and Coating Types

Digital print paper typically features smooth, inkjet-optimized coatings such as microporous or resin-coated surfaces designed to absorb toner or liquid ink efficiently, enhancing color vibrancy and sharpness. Offset print paper commonly uses more traditional coatings like clay or calendered finishes, providing a uniform surface ideal for oil-based inks and higher production runs. The base fiber composition in both papers often involves high-quality wood pulp, but digital papers may include additives to prevent curling and improve feed-through in digital printers.

Surface Texture and Finishing Options

Digital print paper typically features a smoother surface texture designed to absorb toner or ink efficiently, ensuring sharp and vibrant images without smudging. Offset print paper offers a broader variety of surface textures, from matte to glossy, and supports diverse finishing options like varnishing, embossing, and coating, enhancing tactile appeal and durability. Choosing the right paper affects the final look and feel of your print project, with digital papers optimized for quick drying and offset papers providing premium finishing versatility.

Print Quality and Color Reproduction

Digital print paper is specifically designed to absorb toner or ink quickly, ensuring sharp print quality and vibrant color reproduction ideal for short runs and personalized prints. Offset print paper, often coated and smoother, provides superior ink adhesion and consistency, resulting in richer colors and finer detail suited for large volume runs. Your choice depends on whether you prioritize quick turnaround with vivid colors or high-quality, consistent prints for bulk production.

Paper Weight and Thickness Comparison

Digital print paper typically ranges from 60 to 110 gsm, offering thinner and lighter options suited for fast, short-run prints, while offset print paper often starts at 70 gsm and goes up to 300 gsm, providing thicker and heavier options ideal for high-volume, durable prints. Offset print paper thickness can vary between 0.07 mm to 0.3 mm or more, supporting better ink absorption and image quality, whereas digital print paper usually measures between 0.05 mm to 0.15 mm, balancing flexibility and compatibility with digital printers. Your choice depends on whether you prioritize the sturdiness and finish of offset printing or the convenience and economy of digital paper weight and thickness.

Cost Considerations for Print Projects

Digital print paper generally costs less per sheet for small print runs, making it ideal for personalized or short-run projects. Offset print paper can be more economical for large volumes due to bulk purchasing and economies of scale, despite higher initial setup costs. Understanding your project's print quantity helps determine whether digital or offset paper offers the best cost efficiency.

Suitability for Short-Run vs. Long-Run Printing

Digital print paper is ideal for short-run printing because it supports quick turnaround times and variable data printing with minimal setup costs, making it perfect for personalized or on-demand projects. Offset print paper excels in long-run printing due to its durability and cost-efficiency over large volumes, delivering consistent, high-quality results with precise color reproduction. Selecting the right paper depends on your print volume, with digital paper suited for flexibility and offset for large-scale, high-fidelity jobs.

Environmental Impact and Sustainability

Digital print paper typically generates less waste due to on-demand printing and reduced setup requirements, lowering its environmental footprint compared to offset print paper. Offset printing often involves higher energy use and the consumption of chemical-based inks and plates, impacting sustainability negatively. Sustainable initiatives in digital print paper include the use of recycled fibers and soy-based inks, while offset print paper manufacturers increasingly adopt eco-friendly forestry practices and biodegradable consumables to mitigate environmental harm.

Choosing the Right Paper for Your Printing Needs

Digital print paper is designed for short runs and variable data printing, offering fast drying times and smooth surfaces ideal for inkjet and laser printers. Offset print paper, on the other hand, provides superior color accuracy and durability, making it the preferred choice for high-volume projects requiring consistent quality. You should consider factors such as run length, color vibrancy, and paper finish to select the best paper that matches your specific printing needs.

digital print paper vs offset print paper Infographic

libmatt.com

libmatt.com