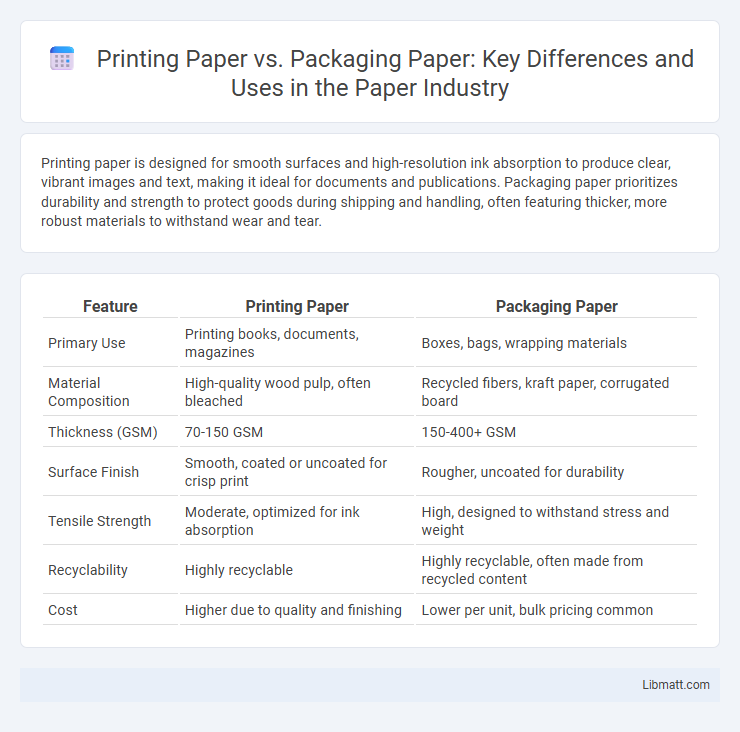

Printing paper is designed for smooth surfaces and high-resolution ink absorption to produce clear, vibrant images and text, making it ideal for documents and publications. Packaging paper prioritizes durability and strength to protect goods during shipping and handling, often featuring thicker, more robust materials to withstand wear and tear.

Table of Comparison

| Feature | Printing Paper | Packaging Paper |

|---|---|---|

| Primary Use | Printing books, documents, magazines | Boxes, bags, wrapping materials |

| Material Composition | High-quality wood pulp, often bleached | Recycled fibers, kraft paper, corrugated board |

| Thickness (GSM) | 70-150 GSM | 150-400+ GSM |

| Surface Finish | Smooth, coated or uncoated for crisp print | Rougher, uncoated for durability |

| Tensile Strength | Moderate, optimized for ink absorption | High, designed to withstand stress and weight |

| Recyclability | Highly recyclable | Highly recyclable, often made from recycled content |

| Cost | Higher due to quality and finishing | Lower per unit, bulk pricing common |

Introduction to Printing Paper and Packaging Paper

Printing paper is specifically designed for high-quality image reproduction and smooth ink absorption, often used in books, magazines, and office documents. Packaging paper is engineered for durability and strength, enabling it to protect goods during shipping and handling with materials like kraft paper or corrugated fiberboard. Both types differ significantly in weight, texture, and functional properties tailored to their distinct applications.

Key Differences Between Printing Paper and Packaging Paper

Printing paper features a smooth surface and high brightness to ensure clear text and vibrant image reproduction, while packaging paper prioritizes strength, durability, and thickness to protect goods during transit. The cellulose fiber composition in printing paper is finer for better ink absorption, whereas packaging paper uses coarser fibers to enhance tear resistance and load-bearing capacity. Printing paper typically has lower grammage (60-120 gsm) compared to packaging paper, which ranges from 150 gsm to over 300 gsm to withstand heavy-duty packaging requirements.

Common Uses of Printing Paper

Printing paper is primarily used for producing books, magazines, brochures, and office documents due to its smooth surface and high print quality. It is designed to absorb ink efficiently, ensuring clear text and vibrant images that enhance readability and visual appeal. Unlike packaging paper, printing paper is often lighter and thinner, optimized for everyday printing tasks and professional publishing needs.

Common Uses of Packaging Paper

Packaging paper is commonly used for wrapping, cushioning, and protecting goods during shipping and storage, ensuring products remain intact and undamaged. It serves applications such as grocery bags, cardboard boxes, and protective layers for fragile items. Your choice of packaging paper directly impacts the durability and sustainability of the packaging solution.

Material Composition and Manufacturing Processes

Printing paper is primarily made from wood pulp with a fine, smooth surface achieved through bleaching and calendaring processes, designed for high ink absorption and clarity. Packaging paper, such as corrugated or kraft paper, uses thicker fibers and incorporates recycled materials, undergoing fewer chemical treatments to enhance strength and durability. Your choice between the two depends on whether you prioritize visual quality or structural integrity in the final product.

Durability and Strength Comparison

Printing paper is generally lighter and less durable, designed for smooth ink absorption and high-quality image reproduction, while packaging paper prioritizes strength and toughness to withstand handling and protect contents. Your choice between the two should consider the required durability, as packaging paper often features higher tear resistance and tensile strength to endure shipping stresses. This makes packaging paper ideal for heavy-duty uses, whereas printing paper suits environments where surface quality and print clarity are critical.

Printability and Surface Quality

Printing paper offers superior printability with smooth surfaces designed for sharp image reproduction and vibrant color accuracy, ensuring crisp text and detailed graphics. Packaging paper prioritizes durability and strength, often with a coarser surface which can affect print quality but enhances resistance to wear and tear during handling and shipping. Your choice depends on whether you need high-definition prints for marketing materials or robust, functional packaging for product protection.

Environmental Impact and Sustainability

Packaging paper is typically designed with higher recycled content and biodegradability to reduce environmental impact, making it a more sustainable choice compared to many types of printing paper that often rely on virgin fibers. Printing paper tends to consume more water and energy during production, and its shorter lifecycle contributes to greater waste unless recycled effectively. To enhance your eco-friendly practices, opting for packaging paper made from sustainably sourced materials supports waste reduction and lowers carbon emissions significantly.

Cost Considerations for Businesses

Printing paper generally incurs lower upfront costs compared to packaging paper due to its lighter weight and simpler production process. Packaging paper, designed for durability and protection, often demands higher material and manufacturing expenses, impacting your overall supply chain budget. Businesses must evaluate cost-effectiveness by balancing the price differences with the functional requirements of each paper type to optimize operational expenses.

Choosing the Right Paper for Your Needs

Choosing the right paper depends on your specific application, with printing paper designed for clarity, smoothness, and ink absorption, while packaging paper prioritizes durability, thickness, and resistance to tearing. Printing paper typically features a finer grain and bright white finish to enhance text and image quality, making it ideal for documents, magazines, and flyers. Packaging paper is engineered for strength and protection, often using kraft or corrugated varieties to securely cushion and transport goods, ensuring your products arrive intact.

Printing paper vs packaging paper Infographic

libmatt.com

libmatt.com