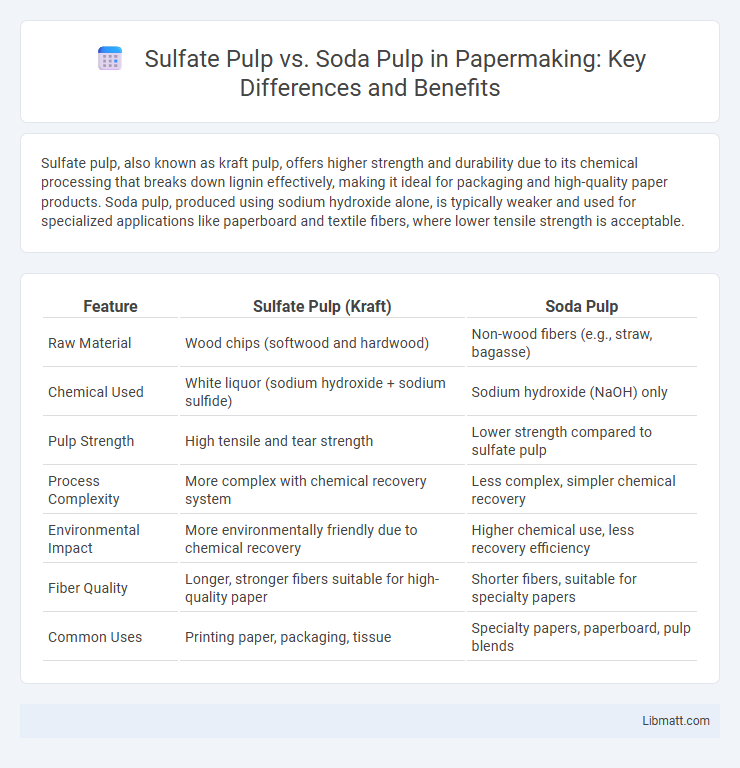

Sulfate pulp, also known as kraft pulp, offers higher strength and durability due to its chemical processing that breaks down lignin effectively, making it ideal for packaging and high-quality paper products. Soda pulp, produced using sodium hydroxide alone, is typically weaker and used for specialized applications like paperboard and textile fibers, where lower tensile strength is acceptable.

Table of Comparison

| Feature | Sulfate Pulp (Kraft) | Soda Pulp |

|---|---|---|

| Raw Material | Wood chips (softwood and hardwood) | Non-wood fibers (e.g., straw, bagasse) |

| Chemical Used | White liquor (sodium hydroxide + sodium sulfide) | Sodium hydroxide (NaOH) only |

| Pulp Strength | High tensile and tear strength | Lower strength compared to sulfate pulp |

| Process Complexity | More complex with chemical recovery system | Less complex, simpler chemical recovery |

| Environmental Impact | More environmentally friendly due to chemical recovery | Higher chemical use, less recovery efficiency |

| Fiber Quality | Longer, stronger fibers suitable for high-quality paper | Shorter fibers, suitable for specialty papers |

| Common Uses | Printing paper, packaging, tissue | Specialty papers, paperboard, pulp blends |

Introduction to Sulfate Pulp and Soda Pulp

Sulfate pulp, also known as kraft pulp, is produced using the kraft process which employs sodium hydroxide and sodium sulfide to break down wood chips, resulting in strong, durable fibers ideal for packaging and high-quality paper production. Soda pulp is made through the soda pulping process where only sodium hydroxide is used as the cooking chemical, primarily applied to non-wood fibers like straw and bagasse, yielding pulp with lower strength and brightness compared to sulfate pulp. Your choice between sulfate and soda pulp depends on the raw material availability and the desired paper properties such as strength, brightness, and environmental impact.

Overview of the Pulping Process

Sulfate pulp, also known as kraft pulp, is produced through the kraft process involving the use of alkaline chemicals like sodium hydroxide and sodium sulfide to break down lignin and separate cellulose fibers, resulting in strong and durable pulp. Soda pulp is made using the soda process, which relies solely on sodium hydroxide for lignin removal, primarily applied to non-wood fibers and yielding pulp with lower strength compared to sulfate pulp. Understanding these differences in your choice of pulping process impacts fiber quality and production efficiency in papermaking.

Chemical Composition Differences

Sulfate pulp, also known as kraft pulp, contains higher amounts of lignin removal due to its use of sodium hydroxide and sodium sulfide in the cooking process, resulting in stronger fibers and less residual lignin compared to soda pulp. Soda pulp relies solely on sodium hydroxide, which leads to lower delignification efficiency and a higher hemicellulose content, producing weaker paper with less strength. Your choice between the two will depend on the desired chemical characteristics and strength properties for your paper products.

Raw Material Suitability

Sulfate pulp, also known as kraft pulp, is highly suitable for processing hardwood and softwood due to its ability to break down lignin while preserving cellulose fibers, making it ideal for high-strength paper products. Soda pulp primarily utilizes non-wood materials such as straw, bagasse, and other agricultural residues, offering an eco-friendly option but with lower fiber strength compared to sulfate pulp. Your choice depends on the raw material availability and the desired quality of the finished paper product.

Environmental Impact Comparison

Sulfate pulp production generates more sulfur emissions and odorous compounds, contributing significantly to air and water pollution compared to soda pulp processes that primarily use sodium hydroxide with fewer harmful byproducts. Soda pulp, derived mainly from non-wood plants, requires less energy and results in lower chemical waste, making it a more sustainable option for reducing your paper manufacturing environmental footprint. Choosing soda pulp supports better ecosystem health due to its milder effluent impact and reduced greenhouse gas emissions.

Strength and Quality of Produced Paper

Sulfate pulp, also known as kraft pulp, produces stronger and more durable paper due to its more effective lignin removal and longer fiber retention compared to soda pulp. Soda pulp results in paper with lower tensile strength and less resistance to wear, making it better suited for lightweight or specialty papers rather than heavy-duty applications. Understanding these differences can help you select the ideal pulp type to optimize the strength and quality of your paper products.

Cost Efficiency and Production Scale

Sulfate pulp production typically incurs higher operational costs due to advanced chemical recovery systems but benefits from greater production scale and consistent fiber quality, making it cost-efficient for large-scale manufacturing. Soda pulp processes have lower initial capital investment and simpler recovery systems, offering cost advantages for smaller-scale production but often face limitations in yield and fiber strength. The choice between sulfate and soda pulp hinges on balancing cost efficiency with production volume, where sulfate pulp is preferred for extensive industrial output and soda pulp suits niche or low-scale applications.

Applications and End Uses

Sulfate pulp, also known as kraft pulp, is widely used in the production of high-strength paper products, such as packaging materials, corrugated boards, and speciality papers due to its superior fiber strength and durability. Soda pulp, derived from softwoods and agricultural residues, is primarily utilized in disposable paper goods, tissue papers, and certain types of printing papers, benefiting from its cost-effectiveness and environmental advantages. Both pulps serve distinct industrial applications based on their chemical compositions, with sulfate pulp favored for heavy-duty uses and soda pulp for lightweight, softer paper products.

Advantages and Disadvantages of Each Method

Sulfate pulp, also known as kraft pulp, offers superior strength and durability due to its chemical lignin removal process, making it ideal for producing high-quality paper and packaging materials, but it has a higher environmental impact due to sulfur emissions and requires more complex recovery systems. Soda pulp, derived from sodium hydroxide cooking, is advantageous for non-wood fibrous materials and has lower sulfur emissions, making it more environmentally friendly, though it typically produces weaker fibers and is less effective for wood pulping. Both methods balance cost, environmental considerations, and end-product requirements, influencing industrial choice based on raw material and product specifications.

Future Trends in Pulping Technology

Future trends in pulping technology emphasize advancing sulfate pulp production through enhanced recovery boilers and cleaner kraft processes to reduce environmental impact and improve fiber quality. Innovations in enzyme-assisted pulping and chemical recycling are expected to increase the sustainability and efficiency of soda pulp manufacturing by minimizing chemical usage and energy consumption. Integration of biorefinery concepts promotes simultaneous extraction of valuable byproducts, positioning both sulfate and soda pulps for more sustainable industrial applications.

Sulfate pulp vs soda pulp Infographic

libmatt.com

libmatt.com