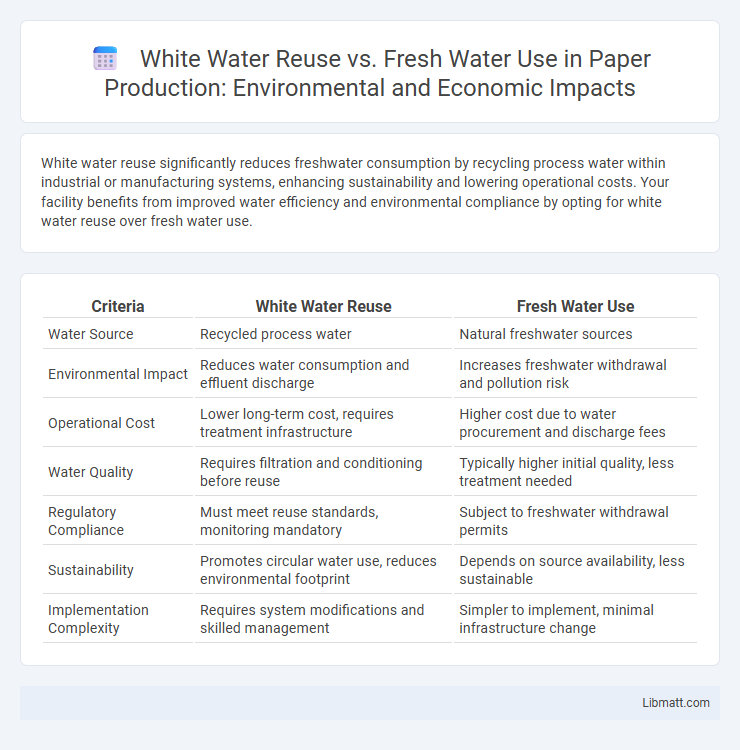

White water reuse significantly reduces freshwater consumption by recycling process water within industrial or manufacturing systems, enhancing sustainability and lowering operational costs. Your facility benefits from improved water efficiency and environmental compliance by opting for white water reuse over fresh water use.

Table of Comparison

| Criteria | White Water Reuse | Fresh Water Use |

|---|---|---|

| Water Source | Recycled process water | Natural freshwater sources |

| Environmental Impact | Reduces water consumption and effluent discharge | Increases freshwater withdrawal and pollution risk |

| Operational Cost | Lower long-term cost, requires treatment infrastructure | Higher cost due to water procurement and discharge fees |

| Water Quality | Requires filtration and conditioning before reuse | Typically higher initial quality, less treatment needed |

| Regulatory Compliance | Must meet reuse standards, monitoring mandatory | Subject to freshwater withdrawal permits |

| Sustainability | Promotes circular water use, reduces environmental footprint | Depends on source availability, less sustainable |

| Implementation Complexity | Requires system modifications and skilled management | Simpler to implement, minimal infrastructure change |

Introduction to Water Use in Industry

Industrial processes rely heavily on water, with fresh water traditionally serving as the primary source for cooling, cleaning, and manufacturing. White water reuse, the practice of recycling treated wastewater or process water within the facility, significantly reduces fresh water intake and minimizes environmental impact. Implementing white water reuse can enhance sustainability and lower operational costs while conserving vital fresh water resources for Your industry.

Defining White Water Reuse

White water reuse involves recycling wastewater within industrial or residential processes to reduce reliance on fresh water sources. This sustainable approach treats and repurposes greywater or treated wastewater for non-potable applications such as irrigation, cooling, and toilet flushing. Implementing white water reuse significantly conserves fresh water, reduces environmental impact, and supports water management strategies in water-scarce regions.

Understanding Fresh Water Consumption

White water reuse significantly reduces fresh water consumption by recycling process water, minimizing the need for continuous withdrawal from natural sources. Understanding fresh water consumption involves analyzing the volume of water used in industrial or domestic operations versus the amount recycled through white water systems. Your efforts to implement white water reuse can drastically lower environmental impact and water scarcity concerns.

Environmental Impacts of White Water Reuse

White water reuse significantly reduces freshwater extraction, lowering strain on natural water bodies and preserving aquatic ecosystems. This practice decreases wastewater discharge into rivers and oceans, minimizing pollution and eutrophication risks. Implementing white water reuse also curtails energy consumption associated with freshwater treatment and distribution, contributing to decreased greenhouse gas emissions.

Environmental Impacts of Fresh Water Use

Fresh water use often leads to habitat depletion, reduced biodiversity, and increased pollution in aquatic ecosystems. White water reuse minimizes these environmental impacts by reducing the demand for fresh water extraction and limiting wastewater discharge into natural bodies. Your sustainable water management strategy can significantly decrease ecological strain by prioritizing white water reuse over fresh water consumption.

Economic Benefits of White Water Reuse

White water reuse significantly reduces water procurement costs by minimizing reliance on expensive fresh water sources. Implementing white water recycling systems decreases wastewater treatment expenses and lowers energy consumption, resulting in substantial operational savings. Companies adopting white water reuse practices also benefit from reduced environmental compliance costs and enhanced sustainability credentials, providing long-term economic advantages.

Cost Considerations of Fresh Water Sourcing

Fresh water sourcing often incurs higher costs due to expenses related to extraction, treatment, and distribution infrastructure, which can strain municipal budgets and industrial operations. In contrast, white water reuse reduces reliance on new freshwater supplies, lowering operational costs by minimizing water purchase fees and decreasing the need for extensive treatment processes. Investing in white water reuse systems promotes economic sustainability by optimizing resource use and mitigating financial risks associated with fresh water scarcity and regulatory pressures.

Technological Solutions for White Water Reuse

Advanced filtration technologies, such as membrane bioreactors and reverse osmosis, effectively treat white water for reuse by removing contaminants and ensuring high water quality. Integration of real-time monitoring systems and automated controls enhances efficiency and reduces operational costs in white water recycling processes. Implementation of these technological solutions significantly lowers fresh water consumption in industrial and manufacturing sectors, promoting sustainable water management practices.

Regulatory Compliance and Water Management

White water reuse significantly enhances regulatory compliance by reducing discharge volumes and meeting stringent wastewater treatment standards, thereby lowering environmental impact and avoiding potential fines. Efficient water management benefits from white water reuse through decreased demand for fresh water sources, promoting sustainable resource utilization and cost savings. This approach supports compliance with water quality regulations while optimizing operational water cycles in industrial and municipal settings.

Future Trends in Industrial Water Practices

Industries increasingly prioritize white water reuse to reduce reliance on fresh water, driven by regulatory pressures and sustainability goals. Advanced treatment technologies such as membrane filtration and biological processes enhance the viability of white water reuse by improving water quality and minimizing contaminants. The future of industrial water management emphasizes closed-loop systems and real-time monitoring to optimize efficiency and reduce environmental impact.

White water reuse vs fresh water use Infographic

libmatt.com

libmatt.com