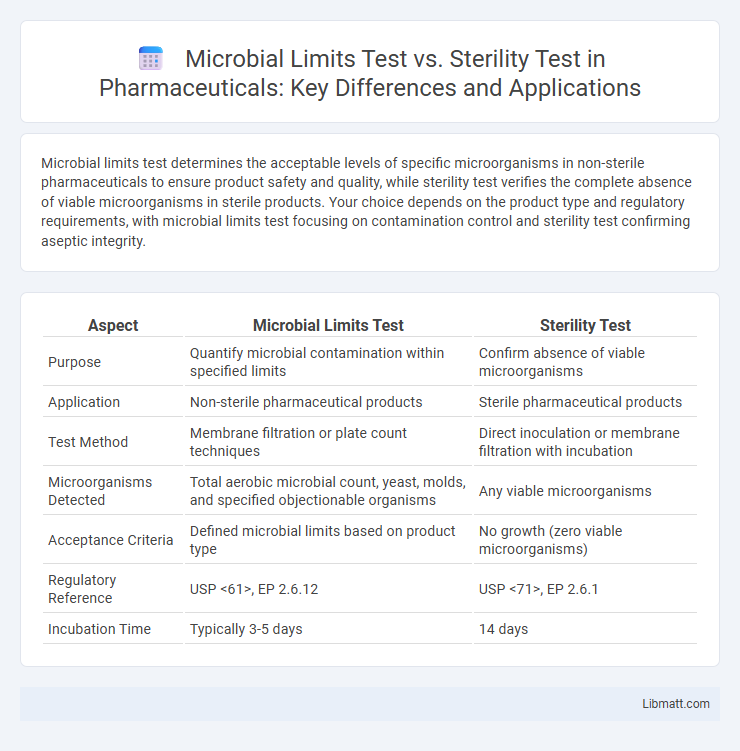

Microbial limits test determines the acceptable levels of specific microorganisms in non-sterile pharmaceuticals to ensure product safety and quality, while sterility test verifies the complete absence of viable microorganisms in sterile products. Your choice depends on the product type and regulatory requirements, with microbial limits test focusing on contamination control and sterility test confirming aseptic integrity.

Table of Comparison

| Aspect | Microbial Limits Test | Sterility Test |

|---|---|---|

| Purpose | Quantify microbial contamination within specified limits | Confirm absence of viable microorganisms |

| Application | Non-sterile pharmaceutical products | Sterile pharmaceutical products |

| Test Method | Membrane filtration or plate count techniques | Direct inoculation or membrane filtration with incubation |

| Microorganisms Detected | Total aerobic microbial count, yeast, molds, and specified objectionable organisms | Any viable microorganisms |

| Acceptance Criteria | Defined microbial limits based on product type | No growth (zero viable microorganisms) |

| Regulatory Reference | USP <61>, EP 2.6.12 | USP <71>, EP 2.6.1 |

| Incubation Time | Typically 3-5 days | 14 days |

Introduction to Microbial Limits Test and Sterility Test

Microbial Limits Test quantifies the presence of specified microorganisms in non-sterile pharmaceutical products, ensuring compliance with pharmacopeial limits to prevent contamination risks. Sterility Test verifies the absence of viable microorganisms in sterile pharmaceutical products, guaranteeing product safety for injection or implant use. Both tests are critical quality control measures aligned with regulatory standards to ensure microbiological safety and efficacy.

Importance in Pharmaceutical Quality Control

Microbial limits test and sterility test are critical components of pharmaceutical quality control, ensuring product safety and compliance with regulatory standards. The microbial limits test quantifies the acceptable level of microbial contamination in non-sterile products, protecting patients from potential infections. Your pharmaceutical product's sterility test confirms the absence of viable microorganisms in sterile products, crucial for maintaining efficacy and preventing harm in sensitive applications like injectables.

Definitions: Microbial Limits Test vs Sterility Test

Microbial Limits Test assesses the quantity and types of microorganisms present in non-sterile products to ensure they fall within acceptable safety standards. Sterility Test evaluates pharmaceutical products or medical devices to confirm the complete absence of viable microorganisms, guaranteeing product sterility. Your choice between these tests depends on whether the product is intended to be sterile or non-sterile.

Key Objectives and Applications

The Microbial Limits Test quantifies the total viable microbial count and detects specified objectionable microorganisms in non-sterile products to ensure safety and compliance with pharmacopeial standards. The Sterility Test confirms the absence of viable microorganisms in sterile pharmaceutical products, guaranteeing product sterility and patient safety. While microbial limits testing applies mainly to non-sterile formulations like creams and oral solids, sterility testing is crucial for injectable solutions, ophthalmic preparations, and surgical implants.

Methodologies: Procedures and Techniques

Microbial limits tests involve quantitative procedures such as membrane filtration, plate count, and most probable number (MPN) to enumerate total viable aerobic microorganisms, fungi, and specific objectionable microbes in non-sterile pharmaceutical products. Sterility tests utilize qualitative methods like direct inoculation and membrane filtration, designed specifically to detect the presence or absence of viable microorganisms, ensuring the product is free from contamination. Both techniques employ incubation at controlled temperatures and durations, but sterility tests demand rigorous aseptic conditions and validated media to confirm complete absence of microbial growth.

Regulatory Standards and Guidelines

Microbial limits tests are governed by regulatory standards such as USP <61> and EP 2.6.12, which specify acceptable microbial counts for pharmaceutical products to ensure safety and quality. Sterility tests follow stringent guidelines outlined in USP <71>, EP 2.6.1, and relevant pharmacopoeias, requiring absence of viable microorganisms in sterile products. Both tests are integral for compliance with FDA and EMA regulations, ensuring products meet prescribed microbial contamination control limits throughout manufacturing and shelf life.

Sensitivity and Specificity Comparison

The Microbial Limits Test offers broader detection by quantifying a wide range of microorganisms but may have lower sensitivity for specific pathogens compared to the Sterility Test, which is highly sensitive and specifically designed to detect the presence or absence of viable microorganisms in sterile products. Sterility Tests employ incubation methods optimized for detecting even minimal contamination, providing higher specificity in ensuring product sterility, whereas Microbial Limits Tests can detect microbial load but may not confirm complete sterility. Your choice between these tests should consider whether detecting total microbial count or confirming absolute sterility aligns best with your product's safety requirements.

Interpretation of Results

Microbial limits test results indicate the total microbial count and presence of specific objectionable organisms, guiding whether a product meets regulatory microbial quality standards. Sterility test results determine the absence or presence of viable microorganisms, confirming if a product is sterile by yielding either no growth (pass) or microbial growth (fail). Your interpretation depends on these criteria, with microbial limits tests assessing contamination levels and sterility tests ensuring complete microbial exclusion.

Common Challenges and Limitations

Microbial limits tests often face challenges related to the detection of low-level contamination due to their sensitivity thresholds, leading to potential false negatives and variability in microbial recovery rates. Sterility tests are limited by their lengthy incubation periods and the inability to detect slow-growing or non-cultivable microorganisms, which can result in false assurances of sterility. Both tests struggle with the presence of antimicrobial agents in samples that can inhibit microbial growth, affecting accuracy and reliability.

Conclusion: Choosing the Appropriate Test

Selecting between the microbial limits test and sterility test depends on the product type and regulatory requirements; microbial limits tests quantify permissible microbial presence in non-sterile products, whereas sterility tests confirm the absence of viable microorganisms in sterile products. Regulatory guidelines from pharmacopeias such as USP <61> and <71> specify the appropriate testing based on the intended use and risk level of the pharmaceutical product. Ensuring compliance with these standards optimizes product safety and quality control in manufacturing processes.

Microbial limits test vs Sterility test Infographic

libmatt.com

libmatt.com