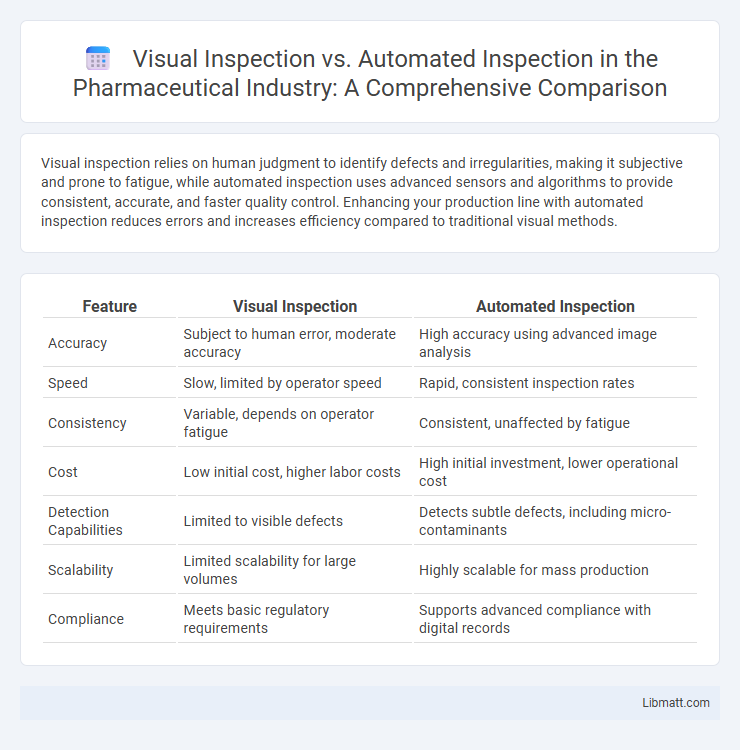

Visual inspection relies on human judgment to identify defects and irregularities, making it subjective and prone to fatigue, while automated inspection uses advanced sensors and algorithms to provide consistent, accurate, and faster quality control. Enhancing your production line with automated inspection reduces errors and increases efficiency compared to traditional visual methods.

Table of Comparison

| Feature | Visual Inspection | Automated Inspection |

|---|---|---|

| Accuracy | Subject to human error, moderate accuracy | High accuracy using advanced image analysis |

| Speed | Slow, limited by operator speed | Rapid, consistent inspection rates |

| Consistency | Variable, depends on operator fatigue | Consistent, unaffected by fatigue |

| Cost | Low initial cost, higher labor costs | High initial investment, lower operational cost |

| Detection Capabilities | Limited to visible defects | Detects subtle defects, including micro-contaminants |

| Scalability | Limited scalability for large volumes | Highly scalable for mass production |

| Compliance | Meets basic regulatory requirements | Supports advanced compliance with digital records |

Introduction to Inspection Methods

Visual inspection relies on human senses to detect defects, making it highly flexible for complex tasks but limited by subjective judgment and fatigue. Automated inspection employs advanced technologies like machine vision and AI algorithms to perform consistent, high-speed analysis, increasing accuracy and efficiency. Both methods are integral in quality control, with automated systems increasingly supplementing human inspection to optimize defect detection in manufacturing processes.

Defining Visual Inspection

Visual inspection involves the manual examination of products or components by trained inspectors to identify defects, inconsistencies, or quality issues using human vision and judgement. This process relies heavily on the inspectors' expertise to detect surface abnormalities, color variations, or structural flaws that may impact product functionality. Visual inspection remains a critical quality control method in many industries despite the rise of automated inspection technologies.

Understanding Automated Inspection

Automated inspection employs advanced technologies such as machine vision, AI algorithms, and sensors to detect defects and inconsistencies in products with high precision and speed. Unlike visual inspection, which relies on human judgment and is prone to fatigue and inconsistency, automated inspection ensures repeatability, scalability, and detailed data collection for quality control. Integrating automated inspection systems enhances manufacturing efficiency by reducing inspection time and improving defect detection accuracy.

Advantages of Visual Inspection

Visual inspection offers the advantage of human intuition and adaptability, allowing inspectors to detect subtle defects and irregularities that automated systems may miss. It is cost-effective for small-scale operations or areas with complex geometries where automation setup is impractical. Furthermore, visual inspection provides immediate feedback and flexibility in changing inspection criteria without the need for reprogramming equipment.

Limitations of Visual Inspection

Visual inspection has inherent limitations such as human error, fatigue, and inconsistent judgment that reduce accuracy and reliability. It often struggles with detecting minute defects and requires significant time and skilled labor, leading to higher operational costs and variability. Your quality control process can benefit from automated inspection systems that provide consistent, rapid, and precise defect detection beyond human capabilities.

Benefits of Automated Inspection

Automated inspection offers consistent accuracy and speed that surpass manual visual inspection, reducing human error and variability in quality control processes. Advanced technologies like machine learning and computer vision enable detection of defects at a micro-level, ensuring higher reliability and traceability in manufacturing. Your production line benefits from increased throughput and cost savings by minimizing downtime and eliminating subjective judgment in inspections.

Challenges with Automated Inspection

Automated inspection faces challenges such as high initial setup costs and complexity in programming systems to accurately identify defects across diverse product variations. Sensitivity to environmental factors like lighting and vibrations can impact the reliability and consistency of automated systems. Your inspection process may also struggle with nuanced quality issues that require human judgment and adaptability, limiting automation effectiveness in certain applications.

Key Differences: Visual vs Automated Inspection

Visual inspection relies on human senses to detect defects and irregularities, offering flexibility but limited consistency and speed. Automated inspection employs advanced technologies like machine vision and AI, ensuring higher accuracy, repeatability, and real-time data analysis. Your choice between the two depends on factors such as inspection complexity, volume, and quality standards.

Choosing the Right Inspection Method

Choosing the right inspection method depends on factors such as inspection speed, accuracy requirements, and complexity of the products. Visual inspection offers flexibility and human judgment for identifying subtle defects, while automated inspection leverages advanced technologies like machine vision and AI for consistent, high-speed defect detection. Prioritizing inspection goals and resource availability ensures an optimal balance between cost efficiency and quality assurance.

Future Trends in Inspection Technologies

Future trends in inspection technologies are rapidly shifting towards increased automation and integration of artificial intelligence, enhancing accuracy and speed beyond traditional visual inspection methods. Automated inspection systems equipped with machine learning algorithms enable real-time defect detection and predictive maintenance, reducing human error and operational costs. Your manufacturing processes will benefit significantly from adopting these advanced inspection technologies that ensure higher quality control and efficiency.

Visual inspection vs automated inspection Infographic

libmatt.com

libmatt.com