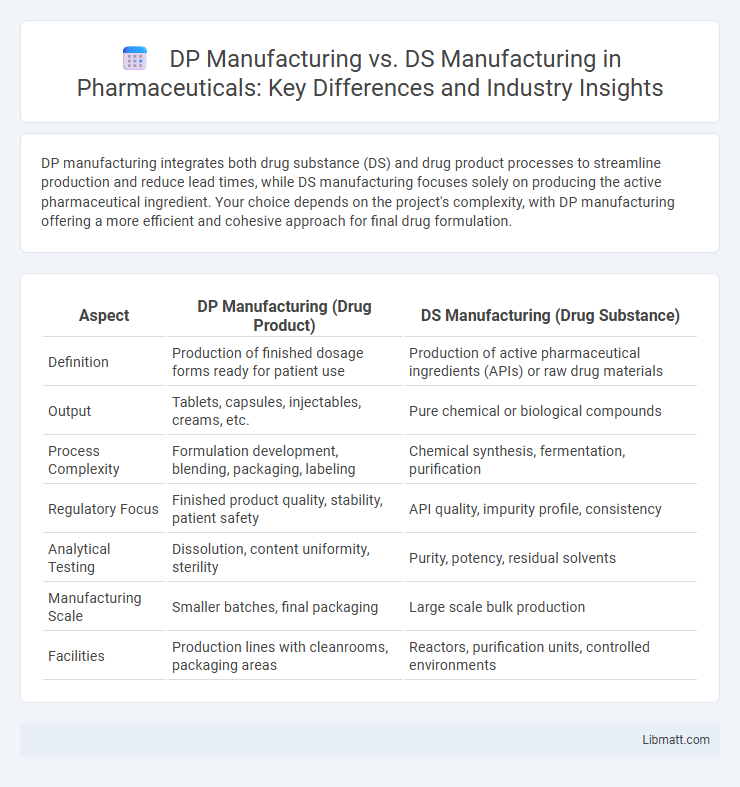

DP manufacturing integrates both drug substance (DS) and drug product processes to streamline production and reduce lead times, while DS manufacturing focuses solely on producing the active pharmaceutical ingredient. Your choice depends on the project's complexity, with DP manufacturing offering a more efficient and cohesive approach for final drug formulation.

Table of Comparison

| Aspect | DP Manufacturing (Drug Product) | DS Manufacturing (Drug Substance) |

|---|---|---|

| Definition | Production of finished dosage forms ready for patient use | Production of active pharmaceutical ingredients (APIs) or raw drug materials |

| Output | Tablets, capsules, injectables, creams, etc. | Pure chemical or biological compounds |

| Process Complexity | Formulation development, blending, packaging, labeling | Chemical synthesis, fermentation, purification |

| Regulatory Focus | Finished product quality, stability, patient safety | API quality, impurity profile, consistency |

| Analytical Testing | Dissolution, content uniformity, sterility | Purity, potency, residual solvents |

| Manufacturing Scale | Smaller batches, final packaging | Large scale bulk production |

| Facilities | Production lines with cleanrooms, packaging areas | Reactors, purification units, controlled environments |

Introduction to DP and DS Manufacturing

Drug Product (DP) manufacturing involves the final formulation, filling, and packaging of a medicinal product ready for patient use, ensuring stability, efficacy, and compliance with regulatory standards. Drug Substance (DS) manufacturing focuses on the synthesis and purification of the active pharmaceutical ingredient (API), which serves as the core therapeutic component in medication. Understanding the distinctions in processes, quality control, and regulatory requirements between DP and DS manufacturing is crucial for optimizing your pharmaceutical production pipeline.

Defining Drug Product (DP) Manufacturing

Drug Product (DP) manufacturing involves the final formulation, filling, and packaging of a pharmaceutical product, ensuring dose uniformity, stability, and patient compliance. Unlike Drug Substance (DS) manufacturing, which focuses on the synthesis and purification of the active pharmaceutical ingredient (API), DP manufacturing integrates excipients and delivers the medication in its final, administrable form. Your understanding of DP manufacturing is essential for quality control, regulatory compliance, and successful drug delivery to patients.

Defining Drug Substance (DS) Manufacturing

Drug Substance (DS) manufacturing involves the production of the active pharmaceutical ingredient (API) through chemical synthesis or biotechnological processes, ensuring purity, potency, and quality before formulation. This phase emphasizes the control of critical process parameters, raw material quality, and compliance with regulatory standards such as GMP to maintain consistency and efficacy. Unlike Drug Product (DP) manufacturing, which focuses on formulation and packaging, DS manufacturing is strictly concerned with the creation and characterization of the therapeutic molecule itself.

Key Differences Between DP and DS Manufacturing

DP manufacturing involves the production of finished drug products like tablets, capsules, or injectables, whereas DS manufacturing focuses on the creation of active pharmaceutical ingredients (APIs) or bulk drugs. DP manufacturing requires stringent packaging, labeling, and formulation processes to ensure dosage accuracy and patient safety, while DS manufacturing emphasizes chemical synthesis, purification, and quality control of raw drug materials. Your understanding of these key differences is crucial for optimizing pharmaceutical production workflows and ensuring regulatory compliance.

Core Processes in Drug Substance Manufacturing

Core processes in Drug Substance (DS) manufacturing involve complex biochemical or chemical synthesis, fermentation, purification, and crystallization to produce the active pharmaceutical ingredient with high purity and potency. Drug Product (DP) manufacturing focuses on formulating the DS into a final dosage form, including blending, granulation, filling, and packaging to ensure stability, dose accuracy, and patient compliance. Your understanding of these core processes is critical for optimizing quality control and regulatory compliance throughout the pharmaceutical production lifecycle.

Core Processes in Drug Product Manufacturing

Core processes in Drug Product (DP) manufacturing involve formulation, blending, granulation, and final dosage form production, ensuring precise drug concentration and stability. Drug Substance (DS) manufacturing focuses on active pharmaceutical ingredient (API) synthesis, purification, and crystallization, emphasizing chemical consistency and purity. Your choice between DP and DS manufacturing impacts downstream processing complexity and regulatory compliance requirements.

Quality Control in DS vs DP Manufacturing

Quality control in Drug Substance (DS) manufacturing emphasizes rigorous purity, potency, and stability testing to ensure the active pharmaceutical ingredient (API) meets regulatory standards before formulation. Drug Product (DP) manufacturing quality control involves comprehensive release testing, including dosage accuracy, uniformity, and packaging integrity to guarantee patient safety and product efficacy. Both processes require strict adherence to Good Manufacturing Practice (GMP) guidelines, but DS quality control focuses more on chemical and biological characterization, while DP quality control prioritizes final product performance and compliance with labeling specifications.

Regulatory Considerations for DS and DP

Regulatory considerations for Drug Substance (DS) manufacturing emphasize stringent control over raw material quality, process validation, and impurity profiling to ensure batch consistency and drug safety. In Drug Product (DP) manufacturing, compliance focuses on formulation stability, container closure integrity, and Good Manufacturing Practices (GMP) to maintain product efficacy and patient safety. Your regulatory strategy must address both DS and DP requirements to streamline approval and ensure seamless market access.

Challenges in Scaling Up DS and DP Manufacturing

Scaling up Drug Substance (DS) manufacturing often encounters challenges such as maintaining consistent purity, yield, and impurity profiles due to complex chemical synthesis or bioprocess variations. Drug Product (DP) manufacturing scaling introduces difficulties in ensuring uniformity, stability, and proper dosage form integrity while adapting to larger batch sizes and regulatory requirements. Your ability to coordinate process optimization and rigorous quality control is crucial to overcoming these hurdles efficiently.

Future Trends in DP and DS Manufacturing

Future trends in Drug Product (DP) manufacturing emphasize continuous manufacturing technologies, real-time quality monitoring, and modular facilities to enhance flexibility and efficiency. Drug Substance (DS) manufacturing is increasingly adopting single-use systems and intensified bioprocessing to reduce contamination risks and accelerate production timelines. Both sectors are leveraging AI-driven process optimization and digital twins to improve scalability and ensure consistent quality in pharmaceutical production.

DP manufacturing vs DS manufacturing Infographic

libmatt.com

libmatt.com