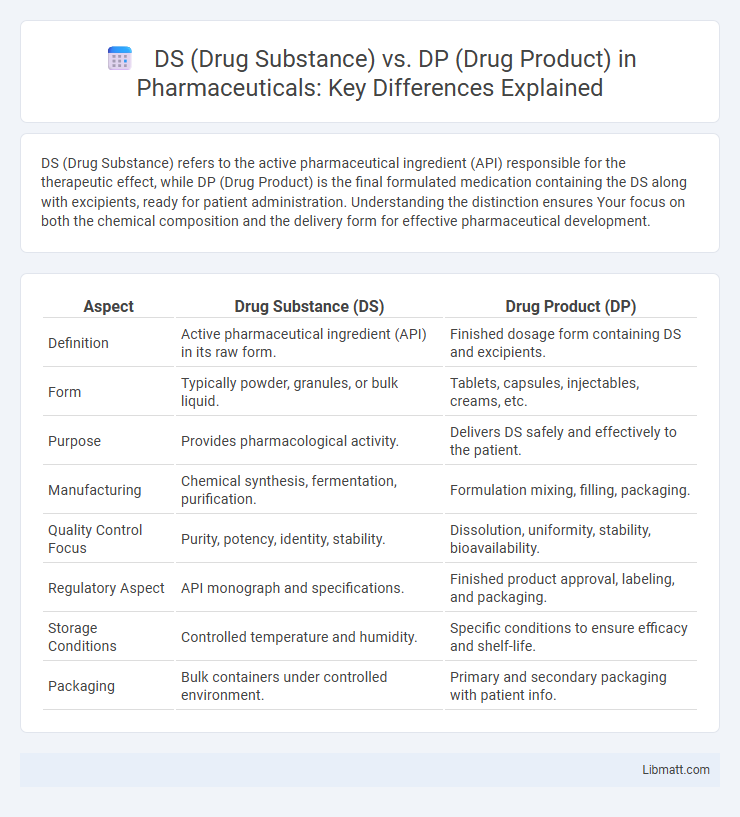

DS (Drug Substance) refers to the active pharmaceutical ingredient (API) responsible for the therapeutic effect, while DP (Drug Product) is the final formulated medication containing the DS along with excipients, ready for patient administration. Understanding the distinction ensures Your focus on both the chemical composition and the delivery form for effective pharmaceutical development.

Table of Comparison

| Aspect | Drug Substance (DS) | Drug Product (DP) |

|---|---|---|

| Definition | Active pharmaceutical ingredient (API) in its raw form. | Finished dosage form containing DS and excipients. |

| Form | Typically powder, granules, or bulk liquid. | Tablets, capsules, injectables, creams, etc. |

| Purpose | Provides pharmacological activity. | Delivers DS safely and effectively to the patient. |

| Manufacturing | Chemical synthesis, fermentation, purification. | Formulation mixing, filling, packaging. |

| Quality Control Focus | Purity, potency, identity, stability. | Dissolution, uniformity, stability, bioavailability. |

| Regulatory Aspect | API monograph and specifications. | Finished product approval, labeling, and packaging. |

| Storage Conditions | Controlled temperature and humidity. | Specific conditions to ensure efficacy and shelf-life. |

| Packaging | Bulk containers under controlled environment. | Primary and secondary packaging with patient info. |

Understanding Drug Substance (DS): Definition and Role

Drug Substance (DS) refers to the active pharmaceutical ingredient (API) responsible for the therapeutic effect in a medication. It undergoes rigorous chemical, physical, and biological characterization to ensure purity, potency, and stability before formulation. The role of DS is critical as it determines the efficacy and safety profile of the final Drug Product (DP), which combines DS with excipients for patient administration.

What is Drug Product (DP)? Key Concepts Explained

Drug Product (DP) refers to the final form of a medication that contains the Drug Substance (DS) combined with excipients, manufactured for patient administration. It encompasses tablets, capsules, injectables, or topical formulations, designed to deliver the active ingredient safely and effectively. Understanding DP is crucial for ensuring your medication meets quality, safety, and efficacy standards from production to patient use.

Core Differences Between DS and DP

Drug Substance (DS) refers to the active pharmaceutical ingredient (API) responsible for therapeutic effects, while Drug Product (DP) is the final dosage form containing the DS along with excipients for administration. DS undergoes chemical synthesis, purification, and characterization to ensure purity and potency, whereas DP involves formulation, manufacturing, packaging, and labeling for patient use. Regulatory requirements for DS focus on API quality and specifications, whereas DP regulations encompass stability, bioavailability, and efficacy of the complete medicinal product.

Regulatory Perspectives: DS vs DP

Regulatory perspectives distinguish Drug Substance (DS) as the active pharmaceutical ingredient (API) subject to strict quality control, manufacturing process documentation, and stability testing to ensure safety and efficacy before formulation. Drug Product (DP) regulations emphasize finished dosage form evaluation, including packaging, labeling, bioavailability, and compliance with Good Manufacturing Practices (GMP) for final consumer use. Both DS and DP require comprehensive regulatory submissions, but DS focuses on chemical characterization while DP centers on therapeutic performance and patient safety.

Manufacturing Process: From Drug Substance to Drug Product

The manufacturing process begins with the Drug Substance (DS), which is the active pharmaceutical ingredient synthesized through chemical, biological, or biotechnological methods. This DS undergoes formulation, blending, and packaging steps to create the Drug Product (DP), the final dosage form administered to patients. Your ability to ensure quality and consistency depends on precise control throughout the transition from DS to DP in the production workflow.

Quality Control Measures for DS and DP

Quality control measures for Drug Substance (DS) focus on verifying purity, potency, and consistency through rigorous analytical testing, including identification, assay, and impurity profiling, to ensure compliance with pharmacopeial standards. For Drug Product (DP), quality control extends to stability testing, dissolution, uniformity of dosage units, and microbial limits to guarantee safety, efficacy, and proper delivery of the medication. Your manufacturing process must integrate these DS and DP quality checks to maintain overall product integrity and regulatory compliance.

Analytical Testing: DS vs DP Approaches

Analytical testing of Drug Substance (DS) focuses on purity, identity, potency, and stability to ensure the raw active pharmaceutical ingredient meets stringent quality standards. Drug Product (DP) testing involves assessing formulation integrity, dosage accuracy, dissolution, and overall product performance to guarantee safety and efficacy for patient use. Your quality control strategy must balance these distinct testing approaches to maintain compliance throughout drug development and manufacturing.

Stability Considerations in DS and DP

Stability considerations in Drug Substance (DS) focus on maintaining the chemical, physical, and microbiological integrity of the active pharmaceutical ingredient (API) under various environmental conditions to ensure potency and safety over time. Drug Product (DP) stability encompasses not only the DS stability but also formulation factors, packaging interactions, and the final container-closure system, all crucial for preserving efficacy and preventing degradation or contamination throughout shelf life. Regulatory guidelines dictate rigorous stability testing protocols tailored to both DS and DP to confirm acceptable shelf life and storage conditions.

Documentation Requirements for DS and DP

Documentation requirements for Drug Substance (DS) include detailed characterization data, manufacturing process descriptions, quality control tests, stability studies, and impurity profiles to ensure consistent identity, purity, and potency. Drug Product (DP) documentation demands comprehensive formulation details, container closure system specifications, manufacturing batch records, in-process controls, and finished product specifications to guarantee safety, efficacy, and quality throughout shelf life. Regulatory submissions require both DS and DP documentation to comply with ICH guidelines, GMP standards, and country-specific requirements for market approval.

Challenges and Best Practices in DS and DP Management

Managing Drug Substance (DS) involves stringent control of raw material quality, synthesis reproducibility, and stability to ensure consistent active pharmaceutical ingredient (API) production. Drug Product (DP) management focuses on formulation challenges, dosage form integrity, and packaging to maintain efficacy and patient safety throughout shelf life. Best practices include implementing robust quality by design (QbD) frameworks, real-time analytical monitoring, and cross-functional collaboration between DS and DP development teams to minimize risks and optimize supply chain reliability.

DS (Drug Substance) vs DP (Drug Product) Infographic

libmatt.com

libmatt.com