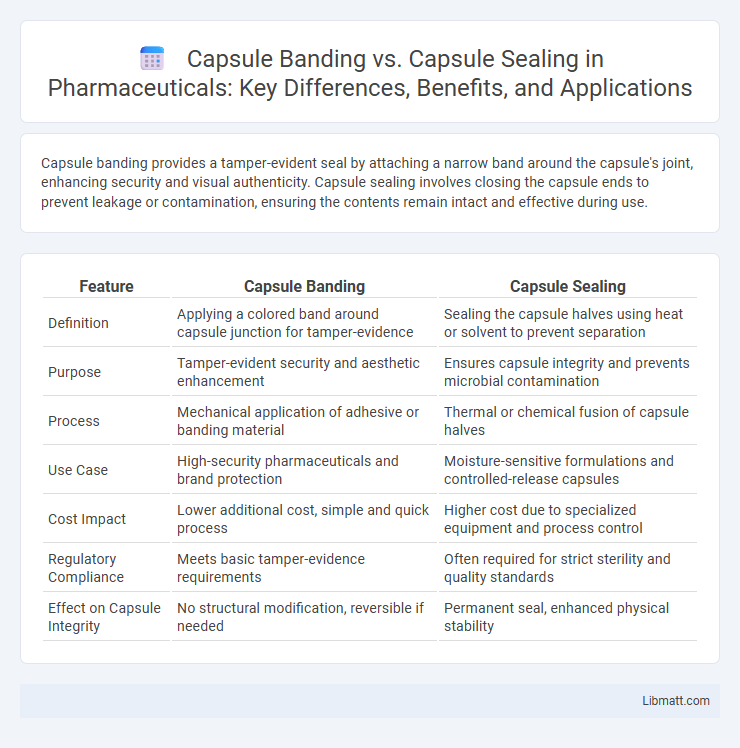

Capsule banding provides a tamper-evident seal by attaching a narrow band around the capsule's joint, enhancing security and visual authenticity. Capsule sealing involves closing the capsule ends to prevent leakage or contamination, ensuring the contents remain intact and effective during use.

Table of Comparison

| Feature | Capsule Banding | Capsule Sealing |

|---|---|---|

| Definition | Applying a colored band around capsule junction for tamper-evidence | Sealing the capsule halves using heat or solvent to prevent separation |

| Purpose | Tamper-evident security and aesthetic enhancement | Ensures capsule integrity and prevents microbial contamination |

| Process | Mechanical application of adhesive or banding material | Thermal or chemical fusion of capsule halves |

| Use Case | High-security pharmaceuticals and brand protection | Moisture-sensitive formulations and controlled-release capsules |

| Cost Impact | Lower additional cost, simple and quick process | Higher cost due to specialized equipment and process control |

| Regulatory Compliance | Meets basic tamper-evidence requirements | Often required for strict sterility and quality standards |

| Effect on Capsule Integrity | No structural modification, reversible if needed | Permanent seal, enhanced physical stability |

Introduction to Capsule Banding and Capsule Sealing

Capsule banding involves applying a secure band around the joint of two capsule halves to enhance tamper evidence and ensure product integrity in pharmaceutical packaging. Capsule sealing, on the other hand, uses a liquid or heat method to bond the capsule halves, providing an airtight seal to protect the contents from contamination and improve shelf life. Understanding the differences between capsule banding and sealing helps you select the appropriate method for your product's safety and quality requirements.

Understanding the Purpose of Capsule Banding

Capsule banding involves applying a colored or printed band around the capsule body and cap, enhancing product security by preventing tampering and ensuring authenticity. This technique maintains capsule integrity during manufacturing and transport, which is crucial for preserving medication efficacy and safety. Understanding the purpose of capsule banding helps you choose packaging solutions that protect your pharmaceutical products and build consumer trust.

Overview of Capsule Sealing Techniques

Capsule sealing techniques primarily involve heat sealing and banding methods designed to improve capsule integrity and prevent tampering. Heat sealing uses a controlled application of heat to fuse the cap and body, creating a tamper-evident seal, while banding applies a polymer or gelatin band around the capsule joint for enhanced security. Both methods enhance product stability and extend shelf life by protecting against moisture, contamination, and leakage.

Key Differences Between Capsule Banding and Sealing

Capsule banding involves applying a colored band around the joint of two capsule halves to enhance tamper-evidence and improve structural integrity, while capsule sealing uses a sealing solution or heat to bond the capsule halves, ensuring complete closure and preventing contamination. The key difference lies in their purpose and application method--banding primarily adds a visual security feature without altering capsule composition, whereas sealing permanently locks the capsule, enhancing protection against leakage and tampering. Your choice between capsule banding and sealing depends on the desired level of protection, branding requirements, and production efficiency.

Material Choices for Banding and Sealing

Capsule banding typically uses a flexible, heat-shrinkable material such as PVC or PETG, providing a tamper-evident seal that can accommodate varying capsule shapes and sizes. Capsule sealing often involves applying a biodegradable or edible polymer-based film to create a secure, airtight closure that enhances product freshness and integrity. Your choice between banding and sealing should consider the compatibility of these materials with your product's storage requirements and regulatory standards.

Advantages of Capsule Banding

Capsule banding offers enhanced tamper-evidence and improved security by firmly securing the capsule halves, reducing the risk of contamination and ensuring product integrity. The band creates a visible seal that assures consumers of the capsule's authenticity and freshness, which is particularly beneficial for pharmaceuticals and nutraceuticals. Your products benefit from increased shelf life and consumer trust through the reliable protection provided by capsule banding.

Benefits of Capsule Sealing

Capsule sealing offers enhanced protection by preventing capsule contents from leaking or tampering, which ensures product purity and extends shelf life. This method improves dosage accuracy and maintains the integrity of sensitive ingredients by creating a secure airtight seal. Your supplements benefit from increased stability and consumer trust through consistent quality and reduced risk of contamination.

Applications in Pharmaceutical Manufacturing

Capsule banding enhances tamper evidence and prevents capsule separation, making it ideal for high-dose or extended-release pharmaceutical products. Capsule sealing provides a more secure hermetic closure, protecting sensitive formulations from moisture and contamination in capsules containing powders or liquids. Your choice influences product stability, dosage accuracy, and regulatory compliance in pharmaceutical manufacturing.

Quality Control Considerations

Capsule banding offers enhanced tamper-evidence and visual quality control through the seamless application of bands that securely join capsule halves, reducing risks of contamination and product integrity compromise. Capsule sealing involves heat or ultrasonic sealing techniques that create airtight barriers, ensuring extended shelf life and preventing leakage or cross-contamination during storage and transport. Quality control processes for banding emphasize precise alignment and adhesion strength, while sealing requires rigorous temperature monitoring and seal integrity testing to guarantee consistent performance.

Choosing Between Capsule Banding and Capsule Sealing

Choosing between capsule banding and capsule sealing depends on your packaging needs and product type. Capsule banding offers tamper-evidence and branding opportunities by applying a printed band around the capsule, ideal for products requiring clear safety indicators. Capsule sealing provides a secure, airtight closure, enhancing freshness and shelf life, making it suitable for perishable goods and pharmaceuticals.

Capsule Banding vs Capsule Sealing Infographic

libmatt.com

libmatt.com