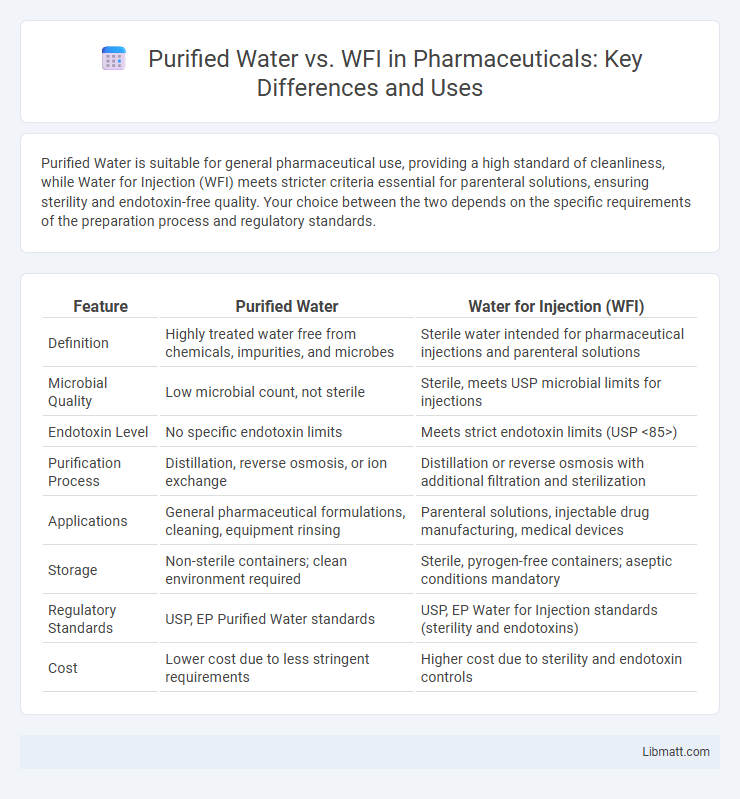

Purified Water is suitable for general pharmaceutical use, providing a high standard of cleanliness, while Water for Injection (WFI) meets stricter criteria essential for parenteral solutions, ensuring sterility and endotoxin-free quality. Your choice between the two depends on the specific requirements of the preparation process and regulatory standards.

Table of Comparison

| Feature | Purified Water | Water for Injection (WFI) |

|---|---|---|

| Definition | Highly treated water free from chemicals, impurities, and microbes | Sterile water intended for pharmaceutical injections and parenteral solutions |

| Microbial Quality | Low microbial count, not sterile | Sterile, meets USP microbial limits for injections |

| Endotoxin Level | No specific endotoxin limits | Meets strict endotoxin limits (USP <85>) |

| Purification Process | Distillation, reverse osmosis, or ion exchange | Distillation or reverse osmosis with additional filtration and sterilization |

| Applications | General pharmaceutical formulations, cleaning, equipment rinsing | Parenteral solutions, injectable drug manufacturing, medical devices |

| Storage | Non-sterile containers; clean environment required | Sterile, pyrogen-free containers; aseptic conditions mandatory |

| Regulatory Standards | USP, EP Purified Water standards | USP, EP Water for Injection standards (sterility and endotoxins) |

| Cost | Lower cost due to less stringent requirements | Higher cost due to sterility and endotoxin controls |

Introduction to Purified Water and WFI

Purified Water is water that has undergone filtration and purification processes to remove impurities, making it suitable for pharmaceutical and laboratory use. Water for Injection (WFI) undergoes further stringent purification, including distillation or reverse osmosis, to meet strict sterile and endotoxin-free standards required for injections and parenteral solutions. Understanding the differences between Purified Water and WFI ensures Your compliance with regulatory standards for specific pharmaceutical applications.

Definition and Classification

Purified water is defined as water that has been treated to remove chemicals and impurities to meet specific quality standards for pharmaceutical and laboratory use. Water for Injection (WFI) is a higher grade of purified water, produced through distillation or reverse osmosis to ensure it is free from pyrogens and suitable for parenteral drug preparation. Both classifications are regulated under pharmacopeial standards such as the USP and EP, with WFI requiring more stringent microbial and endotoxin limits.

Key Differences in Quality Standards

Purified water and WFI (Water for Injection) differ significantly in quality standards, with WFI meeting the highest purity requirements for pharmaceutical applications requiring endotoxin-free water. Purified water typically undergoes processes like reverse osmosis and UV treatment but does not meet the stringent standards for microbial and endotoxin levels essential in sterile preparations. Your selection between purified water and WFI should depend on the specific regulatory guidelines and the critical nature of your pharmaceutical or medical use.

Production Methods and Technologies

Purified Water is typically produced using methods such as reverse osmosis, deionization, or distillation, ensuring removal of most organic and inorganic impurities to meet pharmaceutical-grade standards. Water for Injection (WFI) undergoes more stringent production technologies like multi-stage distillation or membrane filtration coupled with ultrafiltration to achieve pyrogen-free and endotoxin-free quality. Understanding these production methods helps you select the appropriate water grade for specific pharmaceutical or laboratory applications, ensuring compliance with regulatory requirements.

Microbiological and Chemical Specifications

Purified Water and Water for Injection (WFI) differ significantly in microbiological and chemical specifications, with WFI meeting stricter criteria to ensure sterility and minimize endotoxins for parenteral use. Purified Water allows higher microbial limits and total organic carbon (TOC) levels, while WFI requires near absence of endotoxins and lower conductivity. Understanding these differences is crucial for your pharmaceutical processes where compliance with pharmacopeial standards is mandatory for safety and efficacy.

Regulatory Requirements (USP, EP, JP)

Purified Water and Water for Injection (WFI) must comply with distinct regulatory requirements set by pharmacopeias such as USP, EP, and JP, which dictate specific purity standards based on their intended use. Purified Water is primarily regulated under USP <1231>, EP 0169, and JP standards, emphasizing microbial limits and chemical purity for non-injectable applications. WFI, governed by USP <1231>, EP 0169, and JP standards, demands higher purity levels with strict endotoxin limits, made suitable for parenteral administration, requiring specialized production and storage conditions to meet these stringent requirements.

Applications in Pharmaceutical Manufacturing

Purified Water is primarily used in pharmaceutical manufacturing for non-injectable formulations, cleaning, and equipment rinsing, meeting requirements for microbiological quality and chemical purity. Water for Injection (WFI) is essential for injectable drugs, parenteral solutions, and critical sterile processes, adhering to stricter endotoxin and microbial limits due to its higher purity standards. Both water types support compliance with regulatory guidelines such as USP and EP, but WFI demands more rigorous production and storage controls to ensure patient safety.

Storage and Distribution Considerations

Storage and distribution of Purified Water and Water for Injection (WFI) require stringent control to prevent contamination and maintain quality. Purified Water is typically stored in stainless steel tanks with proper sanitization protocols, while WFI demands more rigorous aseptic systems, including sterilized piping and continuous monitoring. Distribution loops for WFI must be maintained at higher temperatures, often with validated steam or heat-circulation methods to ensure endotoxin and microbial control.

Cost Implications and Economic Impact

Purified Water generally incurs lower production and maintenance costs compared to Water for Injection (WFI), making it a more cost-effective choice for industries with moderate purity requirements. WFI demands advanced purification technologies, stringent validation, and higher energy consumption, significantly increasing operational expenses. These cost differences influence economic decisions in pharmaceutical manufacturing, where the balance between compliance needs and budget constraints drives the selection between Purified Water and WFI systems.

Choosing Between Purified Water and WFI

Choosing between Purified Water and Water for Injection (WFI) depends on the intended pharmaceutical application and regulatory requirements. Purified Water is suitable for non-sterile formulations, cleaning, and general manufacturing processes, whereas WFI must meet stringent endotoxin and sterility standards for parenteral and injectable products. Understanding the differences in production methods, such as distillation or reverse osmosis for Purified Water versus distillation or ultrafiltration for WFI, is critical in selecting the appropriate grade to ensure compliance with pharmacopeial standards like USP and EP.

Purified Water vs WFI Infographic

libmatt.com

libmatt.com