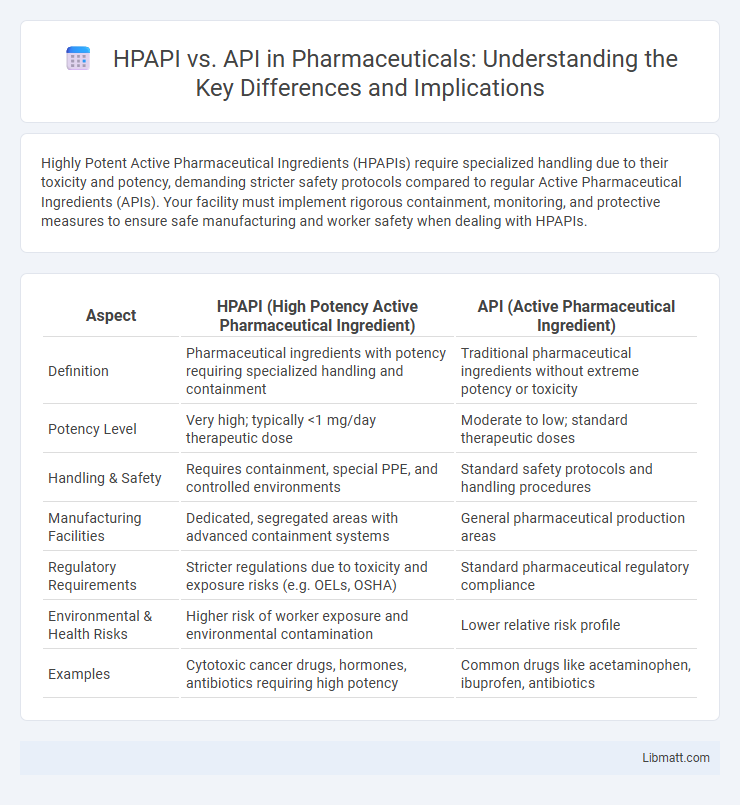

Highly Potent Active Pharmaceutical Ingredients (HPAPIs) require specialized handling due to their toxicity and potency, demanding stricter safety protocols compared to regular Active Pharmaceutical Ingredients (APIs). Your facility must implement rigorous containment, monitoring, and protective measures to ensure safe manufacturing and worker safety when dealing with HPAPIs.

Table of Comparison

| Aspect | HPAPI (High Potency Active Pharmaceutical Ingredient) | API (Active Pharmaceutical Ingredient) |

|---|---|---|

| Definition | Pharmaceutical ingredients with potency requiring specialized handling and containment | Traditional pharmaceutical ingredients without extreme potency or toxicity |

| Potency Level | Very high; typically <1 mg/day therapeutic dose | Moderate to low; standard therapeutic doses |

| Handling & Safety | Requires containment, special PPE, and controlled environments | Standard safety protocols and handling procedures |

| Manufacturing Facilities | Dedicated, segregated areas with advanced containment systems | General pharmaceutical production areas |

| Regulatory Requirements | Stricter regulations due to toxicity and exposure risks (e.g. OELs, OSHA) | Standard pharmaceutical regulatory compliance |

| Environmental & Health Risks | Higher risk of worker exposure and environmental contamination | Lower relative risk profile |

| Examples | Cytotoxic cancer drugs, hormones, antibiotics requiring high potency | Common drugs like acetaminophen, ibuprofen, antibiotics |

Introduction to APIs and HPAPIs

APIs (Active Pharmaceutical Ingredients) are the essential components in drug formulations responsible for therapeutic effects, while HPAPIs (Highly Potent Active Pharmaceutical Ingredients) are specialized APIs characterized by their increased potency and require stringent handling and containment procedures. The manufacturing and processing of HPAPIs demand advanced safety measures and specialized equipment to protect workers and prevent cross-contamination in pharmaceutical production facilities. Your understanding of the distinct regulatory and operational challenges between APIs and HPAPIs is crucial for effective pharmaceutical development and manufacturing compliance.

Defining HPAPI: What Makes an API “Highly Potent”?

Highly Potent Active Pharmaceutical Ingredients (HPAPIs) are substances characterized by their exceptional biological activity at very low concentrations, distinguishing them from conventional Active Pharmaceutical Ingredients (APIs). These compounds require specialized handling and containment measures due to their potential toxicity and potency, ensuring safety and efficacy in pharmaceutical manufacturing. Your understanding of HPAPIs involves recognizing their critical impact on drug formulation and the necessity for rigorous control protocols in production environments.

Key Differences Between HPAPI and Conventional API

HPAPI (Highly Potent Active Pharmaceutical Ingredient) differs from conventional API primarily in toxicity and handling requirements, with HPAPIs demanding specialized containment measures to protect workers from exposure due to their extreme potency. The manufacturing process for HPAPIs involves advanced engineering controls, such as isolators and closed systems, to ensure safety and prevent cross-contamination, whereas conventional APIs typically follow standard Good Manufacturing Practices (GMP). Your choice between HPAPI and conventional API depends on the therapeutic target and safety protocols required for drug production and formulation.

Importance of HPAPIs in Modern Pharmaceuticals

HPAPIs (Highly Potent Active Pharmaceutical Ingredients) are crucial in modern pharmaceuticals due to their ability to target diseases with increased efficacy at lower doses compared to standard APIs (Active Pharmaceutical Ingredients). Their potency demands specialized handling, manufacturing, and containment equipment to ensure safety for workers and patients. Your ability to safely manage HPAPIs directly impacts the development of advanced therapeutics and precision medicines.

Safety and Handling Considerations for HPAPIs

Highly Potent Active Pharmaceutical Ingredients (HPAPIs) require stringent safety and handling protocols due to their increased toxicity and potential health risks compared to standard APIs. Specialized containment systems, such as isolators and closed transfer devices, are crucial to prevent operator exposure and cross-contamination during manufacturing and processing. Rigorous personal protective equipment (PPE), comprehensive employee training, and validated cleaning procedures are essential components to ensure safe handling and maintain product integrity.

Manufacturing Challenges: HPAPI vs API

Manufacturing Challenges in handling High Potency Active Pharmaceutical Ingredients (HPAPI) versus Active Pharmaceutical Ingredients (API) primarily involve stringent containment and safety measures due to the toxicity and potency of HPAPIs. Specialized equipment, advanced engineering controls, and rigorous environmental monitoring are required to prevent cross-contamination and protect worker safety in HPAPI production. In contrast, API manufacturing often faces less complex containment requirements but still demands precise control over reaction conditions and purity standards to ensure product quality.

Regulatory Requirements for HPAPI Production

HPAPI (Highly Potent Active Pharmaceutical Ingredients) production demands stringent regulatory requirements due to their toxicity and potential health risks. Facilities must implement specialized containment strategies, validated cleaning procedures, and comprehensive risk assessments to prevent cross-contamination and ensure operator safety. Your manufacturing processes must comply with guidelines from agencies such as the FDA and EMA, emphasizing controlled environments and robust documentation to meet these rigorous standards.

Cost Implications: HPAPI versus Standard API

Highly Potent Active Pharmaceutical Ingredients (HPAPIs) incur significantly higher manufacturing and handling costs compared to standard APIs due to stringent containment systems, specialized equipment, and enhanced safety protocols required to prevent cross-contamination and ensure worker protection. The investment in advanced facilities and rigorous quality control measures elevates operational expenses, which impacts the overall drug development budget and pricing strategies. In contrast, standard APIs benefit from more conventional production environments and lower safety requirements, resulting in comparatively reduced cost implications.

Market Trends and Future Outlook for HPAPIs

The HPAPI (Highly Potent Active Pharmaceutical Ingredient) market is experiencing rapid growth driven by increased demand for targeted therapies in oncology, immunology, and rare diseases. Innovations in manufacturing technologies, such as containment systems and advanced delivery mechanisms, enhance safety and efficiency, positioning HPAPIs as critical components in personalized medicine. Your investment in HPAPI development aligns with a future where stringent regulatory frameworks and rising healthcare expenditures fuel sustained market expansion and innovation.

Conclusion: Choosing Between HPAPI and API for Drug Development

Selecting between HPAPI and API for drug development hinges on compound potency, safety requirements, and manufacturing capabilities. HPAPIs demand stricter containment and handling protocols due to their high toxicity, driving up production complexity and costs compared to APIs. Opting for HPAPI formulations suits targeted therapies requiring minimal dosage, while APIs remain ideal for less potent drugs with broader therapeutic windows.

HPAPI vs API Infographic

libmatt.com

libmatt.com